| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 18V494

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components POWER TRAIN

Potential Number of Units Affected 702

Half Shaft Bearing Cage may Break

If the halfshaft bearing cage breaks, the halfshaft may not be able to transmit engine power, causing a loss of drive or it can allow the vehicle to move while in the “Park” position. Either condition may increase the risk of a crash.

Summary

Chrysler (FCA US LLC) is recalling certain 2018 Jeep

(FCA US LLC) is recalling certain 2018 Jeep Cherokee all-wheel-drive vehicles. The bearing cage for the right front halfshaft assembly may not have been properly heat treated, possibly resulting in the bearing cage breaking and a potential halfshaft assembly failure.

Cherokee all-wheel-drive vehicles. The bearing cage for the right front halfshaft assembly may not have been properly heat treated, possibly resulting in the bearing cage breaking and a potential halfshaft assembly failure.

Remedy

Chrysler will notify owners, and dealers will replace the front right halfshaft assemblies, free of charge. The recall began September 20, 2018. Owners may contact Chrysler

will notify owners, and dealers will replace the front right halfshaft assemblies, free of charge. The recall began September 20, 2018. Owners may contact Chrysler customer service at 1-800-853-1403. Chrysler

customer service at 1-800-853-1403. Chrysler ’s number for this recall is U78.

’s number for this recall is U78.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

September 2018

Dealer Service Instructions for:

Safety Recall U78 / NHTSA 18V-494

Right Front Halfshaft

Remedy Available

| 2018 | (KL) | Jeep Cherokee Cherokee |

NOTE: This recall applies only to the above vehicles equipped with all-wheeldrive built from October 30, 2017 through November 03, 2017 (MDH 103013 through 110311).

| IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. |

Subject

The right front halfshaft assembly on about 700 of the above vehicles was built with a bearing cage that was improperly heat treated which may result in the bearing cage breaking and a potential halfshaft assembly failure. A broken halfshaft bearing cage may lead to the loss of ability of the halfshaft assembly to transmit torque through the all-wheel-drive system which results in a loss of motive power if driving or the inability of the vehicle to maintain PARK if stationary. A sudden loss of motive power can cause vehicle crash without prior warning. An inability to maintain PARK may result in unintended vehicle movement which increases the risk of injury to vehicle occupants or bystanders, or can cause vehicle crash without prior warning.

Repair

Replace the right front halfshaft assembly on all affected vehicles.

Parts Information

| Description | Part Number |

|---|---|

| Halfshaft, Right | CSAJU781AA |

| Each package contains the following components: | |

| Description | Quantity |

| Halfshaft, Right | 1 |

| Nut, Lower Ball Joint | 1 |

| Nut, Hub Nut | 1 |

Parts Return

No parts return required for this campaign.

Special Tools

The following special tool is required to perform this repair:

| Press, Ball Joint |

| Front Hub Staking |

Service Procedure

Replace Right Front Halfshaft

NOTE: Never handle the halfshaft assembly by the inner or outer boots. This can cause damage to the boot, which will allow contaminants to enter the Constant Velocity (CV) joint.

NOTE: The inner tripod joint is designed with a retention feature that prevents the tripod rollers from coming out of the inner joint housing up to a specific load. If this feature is overcome and the rollers are pulled past the retention feature the joint will lock up and no longer function properly. The entire halfshaft assembly must be replaced if this occurs.

- Raise and support the vehicle.

- Remove the right front tire and wheel assembly.

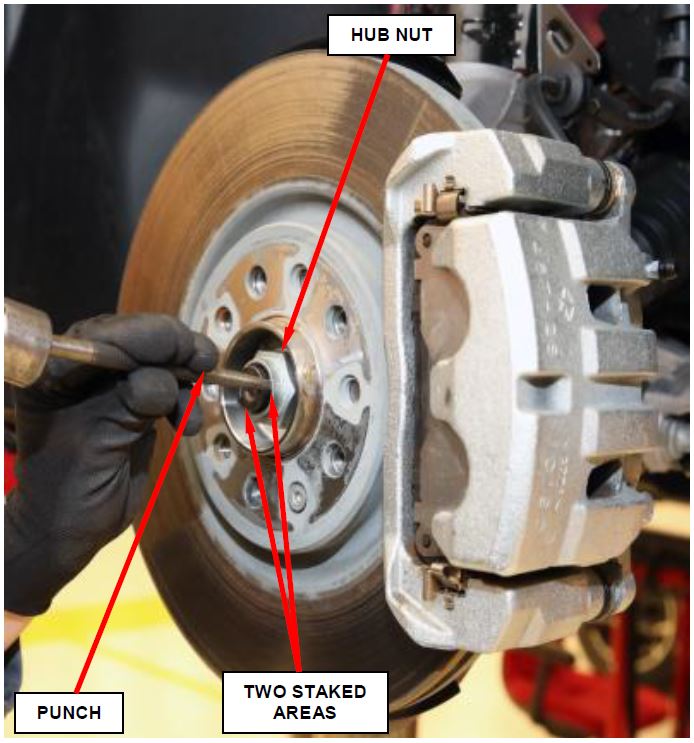

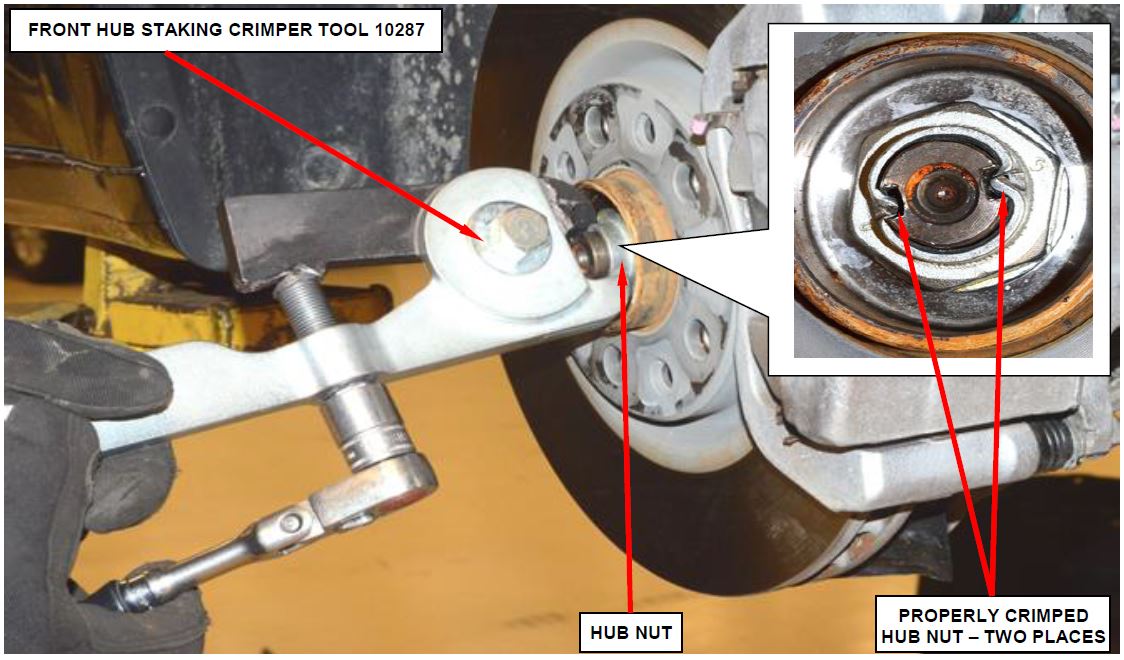

- Using a suitable punch, lift the two staked areas in the hub nut to avoid damaging the halfshaft (Figure 1).

- While a helper applies the brakes to keep the hub from rotating, remove and discard the hub nut from the halfshaft. The original hub nut is not reusable (Figure 1).

Figure 1 – Hub Nut

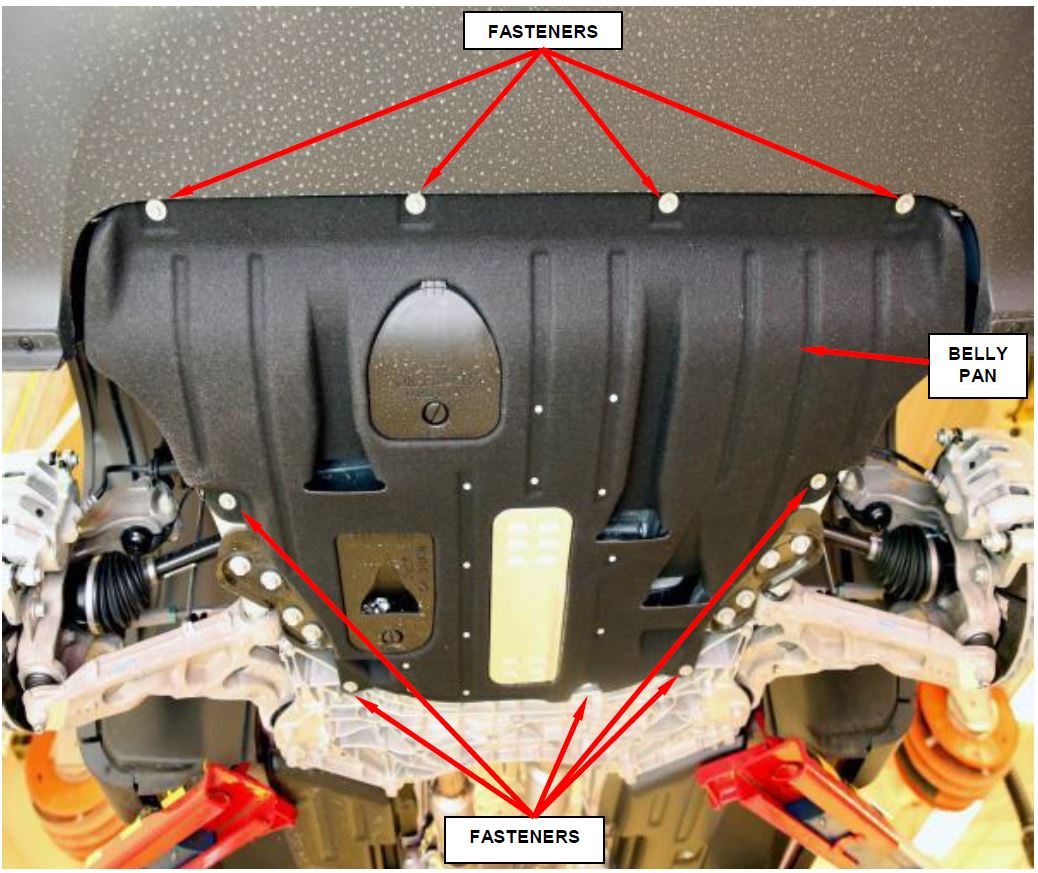

- Remove and save the nine engine belly pan fasteners and remove the belly pan, if equipped (Figure 2).

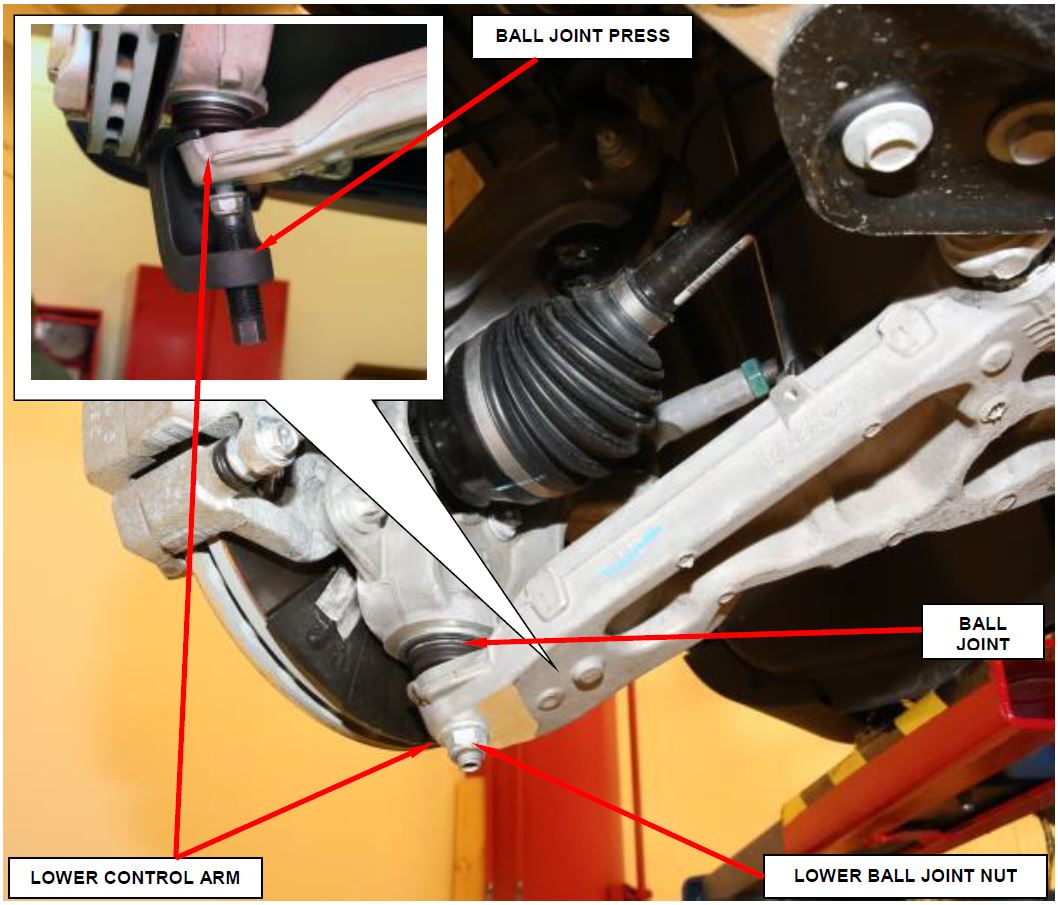

NOTE: Use care when separating the ball joint stud from the knuckle so the ball joint boot does not get cut.

Figure 2 – Belly Pan

- Remove and discard the lower ball joint nut (Figure 3).

NOTE: Hand start the lower ball joint nut to help protect the lower ball joint thread while using the Ball Joint Press.

- Using the Ball Joint Press C-4150A separate the ball joint stud from the lower control arm (Figure 3).

Figure 3 – Lower Ball Joint

NOTE: After separating the control arm from the knuckle, do not let it swing rapidly back up. This can tear the ball joint dust boot.

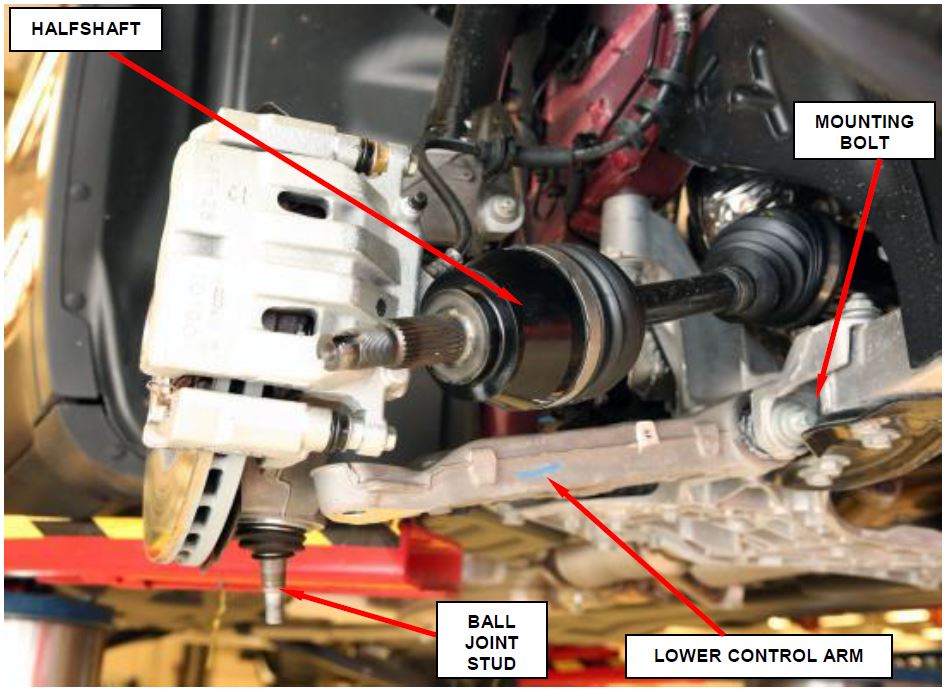

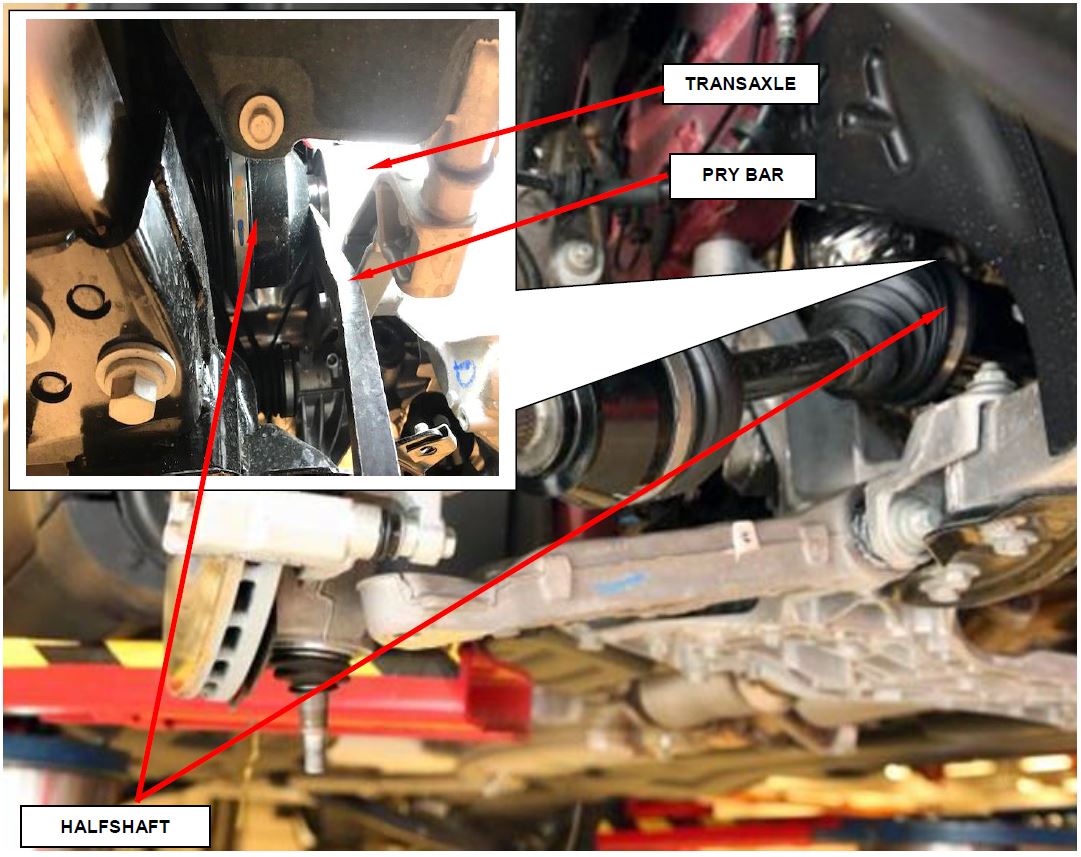

- Insert a pry bar in the opening between the control arm front mounting bolt and the front fascia support beam (Figure 4).

NOTE: The halfshaft may stick in the hub bearing during removal. A dead-blow or plastic hammer can be used to tap the halfshaft inward and out of the hub bearing.

- Pry down on the control arm until the ball joint stud is clear of the control arm. Position the knuckle assembly to the side until it is clear of the ball joint stud. Slowly release the control arm.

- Swing the steering knuckle outward and off the halfshaft end (Figure 4).

Figure 4 – Lower Control Arm

- Using a pry bar or equivalent tool release the halfshaft from the transaxle and remove the halfshaft from the vehicle (Figure 5).

Figure 5 – Halfshaft (Transaxle End)

- Position the NEW halfshaft under the vehicle and over the lower control arm.

NOTE: Lightly apply grease to the splines prior to installation.

NOTE: When installing the right halfshaft on All Wheel Drive (AWD) vehicles with a single speed Power Transfer Unit (PTU) and manual transaxle, use care when installing the halfshaft as the shaft must pass through multiple oil seals.

- Install the halfshaft into the transaxle and lightly twist until halfshaft spline slides all the way into the transaxle.

NOTE: If circlip is fully engaged, tripod joint will not be removable from transaxle by hand.

- Swing the steering knuckle outward and engage the halfshaft end into the hub bearing spline.

- Push the lower control arm downward until ball joint stud can enter the bottom of the knuckle.

- Insert the ball joint stud into the lower control arm.

- Install a NEW lower ball joint to control arm nut and tighten to 18 ft. lbs. Plus 175° (25 N•m Plus 175°) (Figure 3).

Figure 6 – Crimp Halfshaft Hub Nut with Special Tool 10287

NOTE: Always install a NEW hub nut. The original hub nut is one time use only and must be discarded when removed.

- Install a NEW hub nut and while a helper applies the brakes, tighten the nut to 148 ft. lbs. (200 N•m).

NOTE: Do not use air tools on staking tool while staking hub nut.

- Using the Tool, Front Hub Staking 10287, align the leading cutting edge of Tool, Front Hub Staking 10287 with the top left side channel on axle as shown. Tighten fastener on Tool, Front Hub Staking 10287 with hand tools until the threads bottom out completely (Figure 6).

NOTE: The hub nut must be staked so that it looks similar to Figure 6. Both edges must be split and bent into the shape shown (Figure 6). The staking must be opposite of the direction to tighten the nut.

- If equipped, install the engine belly pan and tighten the fasteners securely (Figure 2).

- Install the tire and wheel assembly and tighten the lugs to 96 ft. lbs. (130 N•m).

- Return the vehicle to the customer.

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments.

Use the following labor operations number and time allowances:

| Labor Operation Number | Time Allowance | |

|---|---|---|

| Replace right front halfshaft | 02-U7-81-82 | 0.5 hours |

| Floor Plan Reimbursement | 95-95-95-97 | Calculate See Below |

Floor Plan Reimbursement represents the vehicle’s average daily allowance (see table below) multiplied by the number of days the vehicle was in dealer inventory and not available for sale. This reimbursement is limited to the number of days from the date of the stop sale to the date that the remedy was made available. Note: If the vehicle was received by your dealership (KZX date) AFTER the stop sale date, you will use the KZX date instead of the stop sale date. For this Recall, the stop sale was initiated on 08/02/2018 and the remedy was made available on 09/20/2018, therefore, the number of days cannot exceed 49 days.

| Vehicle | Average Daily Allowance |

2018 (KL) Jeep Cherokee Cherokee |

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

This notice applies to your vehicle,

[Model Year and Model] VIN XXXXXXXXXXXXXXXXX U78/NHTSA 18V-494

LOGO

VEHICLE PICTURE

YOUR SCHEDULING OPTIONS

- RECOMMENDED OPTION Call your authorized Chrysler

/ Dodge

/ Dodge / Jeep

/ Jeep / RAM

/ RAM / Dealership

/ Dealership - Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can confirm part availability and help schedule an appointment

- Visit recalls.mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App.

QR Code

Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above.

DEALERSHIP INSTRUCTIONS

Please reference Safety Recall U78.

IMPORTANT SAFETY RECALL

Right Front Halfshaft

Dear [Name],

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

FCA has decided that a defect, which relates to motor vehicle safety, exists in certain [2018 Jeep Cherokee] vehicles.

It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers.

WHY DOES MY VEHICLE NEED REPAIRS?

The right front halfshaft assembly on your vehicle [1] was built with a bearing cage that was improperly heat treated which may result in the bearing cage breaking and a potential halfshaft assembly failure. A broken halfshaft bearing cage may lead to the loss of ability of the halfshaft assembly to transmit torque through the all-wheel-drive system which results in a loss of motive power if driving or the inability of the vehicle to maintain PARK if stationary. A sudden loss of motive power can cause vehicle crash without prior warning. An inability to maintain PARK may result in unintended vehicle movement which increases the risk of injury to vehicle occupants or bystanders, or can cause vehicle crash without prior warning.

HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE?

FCA will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will replace the right front halfshaft assemblies on all affected vehicles. In addition, your dealer will require your vehicle for proper check-in, preparation, and check-out during your visit. Your time is important to us; please be aware that these steps may require more time. The estimated repair time is two hours. We recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership.

TO SCHEDULE YOUR FREE REPAIR CALL

YOUR CHRYSLER, DODGE, JEEP OR RAM DEALER TODAY

WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED?

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed.

We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Assistance/Field Operations

Fiat Chrysler

Chrysler Automobiles US LLC

Automobiles US LLC

Mr. Mrs. Customer

1234 Main Street

Hometown, MI 48371

[1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information.

[2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-4249153), or go to safercar.gov.

[3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement.

Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

U78

September 2018

Loading...

Loading...

Owner Notification Letter

Loading...

Loading...

Safety Recall Advanced Communication – U78

08/02/2018

Loading...

Loading...

FCA US LLC Chronology

2018 Jeep Cherokee Halfshaft Bearing Cage Improper Heat Treat

Cherokee Halfshaft Bearing Cage Improper Heat Treat

Submitted on July 26, 2018

Loading...

Loading...

Recall Acknowledgement

August 9, 2018

Loading...

Loading...

Latest Recalls Documents

- Genuine OEM Dodge

/Mopar factory fit part

/Mopar factory fit part - The approved automatic transmission fluid for all vehicles factory filled with ATF+4.

- Do not use this transmission fluid for either Crossfire or Sprinter automatic transmissions.

- Caution: This product can expose you to chemicals which might cause cancer and birth defects or other reproductive harm.

- Genuine OEM Dodge

/Mopar factory

/Mopar factory

- Exceeds demands of automatic transmissions of most Chrysler

, Dodge

, Dodge , Ram

, Ram & other Stellantis vehicles

& other Stellantis vehicles - High-efficiency conditioners protect and prolong the elasticity of seals, preventing leaks

- Advanced technology reduces wear, foaming, and oxidation while protecting transmission performance

- Superior high & low temp performance supports transmission fluid in all weather & driving situations

- Full synthetic formula with advanced additives protects against transmission breakdown better than conventional fluids

- (1) MOPAR ATF plus 4, 1. 3 Gallon Bottle

- Part number: 68218058AC

- Package Weight: 4.241 kilograms

- Included components: 68218058AC

- For best performance, follow the manufacturer's recommendations in your vehicle owner’s manual.

- Genuine OEM Dodge

/Mopar factory fit part

/Mopar factory fit part

- Full Synthetic formula exceeds ATF plus3 requirements

- Certified and approved for all Chrysler

cars and trucks that require ATF plus4, Mopar ATF plus3, ATF plus2, ATF plus2 Type 7176, or ATF plus

cars and trucks that require ATF plus4, Mopar ATF plus3, ATF plus2, ATF plus2 Type 7176, or ATF plus - Technologically advanced, full synthetic formulation provides superior transmission life

- Engineered with superior base oils to ensure superb low and high temperature performance

- Meets or Exceeds Fiat

Chrysler

Chrysler ATF plus4 requirements

ATF plus4 requirements

- MOPAR Genuine Parts & Accessories

- Automatic Transmission Fluid

- Synthetic

- 5 Liter

- 1.3 Gallon

- Fully compatible with all transmissions that require Mopar ATF+, Mopar ATF+2 and Mopar ATF+3

- Improved thermal stability for longer fluid life

- Improved viscosity stability for consistent transmission operation

- Specific frictional properties for smooth clutch engagement

- Contains special additives to prevent rust corrosion and wear for longer life

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.