| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 15V115

Component(s): ELECTRICAL SYSTEM

Potential Number of Units Affected: 339,525

Manufacturer: Chrysler (FCA US LLC)

(FCA US LLC)

Fuel Pump Relay may Fail Resulting in Stall

A vehicle stall increases the risk of a crash.

SUMMARY:

Chrysler (FCA US LLC) is recalling certain model year 2012-2013 Jeep

(FCA US LLC) is recalling certain model year 2012-2013 Jeep Grand Cherokee vehicles manufactured September 17, 2010, to August 19, 2013, and equipped with a 3.6, 5.7 or 6.4 liter engine, and 2012-2013 Dodge

Grand Cherokee vehicles manufactured September 17, 2010, to August 19, 2013, and equipped with a 3.6, 5.7 or 6.4 liter engine, and 2012-2013 Dodge Durango vehicles manufactured January 18, 2011, to August 19, 2013, and equipped with a 3.6 or 5.7 liter engine.

Durango vehicles manufactured January 18, 2011, to August 19, 2013, and equipped with a 3.6 or 5.7 liter engine.

In the affected vehicles, the fuel pump relay inside the Totally Integrated Power Module (TIPM-7) may fail, causing the vehicle to stall without warning.

CONSEQUENCE:

A vehicle stall increases the risk of a crash.

REMEDY:

Chrysler will notify owners, and dealers will replace the fuel pump relay with one external to the TIPM.

will notify owners, and dealers will replace the fuel pump relay with one external to the TIPM.

The recall began on August 7, 2015.

Owners may contact Chrysler customer service at 1-800-853-1403.

customer service at 1-800-853-1403.

Chrysler ’s number for this recall is R09.

’s number for this recall is R09.

Note: This recall is an expansion of recall 14V-530.

NOTES:

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

July 2015

Dealer Service Instructions for:

Safety Recall R09 / NHTSA 15V-115 Fuel Pump Relay

Models

IMPORTANT: Many of the vehicles within the above build period have already been inspected or repaired and, therefore, have been excluded from this recall.

| IMPORTANT: Some of the involved vehicles may be in dealer used vehicle inventory. Dealers should complete this recall service on these vehicles before retail delivery. Dealers should also perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. |

Subject

The Totally Integrated Power Module (TIPM) on about 335,000 of the above vehicles contains an internal fuel pump relay that could operate intermittently or fail without warning. An intermittent or failed fuel pump relay could cause the engine to stall while driving and cause a crash without warning.

Repair

The TIPM internal fuel pump relay must be disabled and an external fuel pump relay must be installed.

Parts Information

| Description | Part Number |

|---|---|

| External Fuel Pump Relay Package | CBWPR091AA |

| Each package contains the following components: | |

| Description | Quantity |

| Relay, Fuel Pump | 1 |

| Harness, Wiring | 1 |

| Tube, Shrink | 3 |

| Crimp, Brass | 3 |

| Pin, Push | 1 |

| Strap, Plastic Tie | 3 |

Each dealer to whom vehicles in the recall were assigned will receive enough External Fuel Pump Relay Packages to service about 20% of those vehicles.

Special Tools

The following special tools are required to perform this repair:

| Wire splice crimp tool |

| Pick, Terminal |

* NOTE: One wire splice crimp tool was mailed to each Chrysler /Jeep

/Jeep /Dodge

/Dodge dealer free of charge in June, 2007.

dealer free of charge in June, 2007.

Additional wire splice crimp tools can be purchased, at dealer expense, by contacting Mopar Essential Tools and Service Equipment at 1-855-298-2687 or www.MoparEssentialTools.com during regular business hours. Contact Mopar Essential Tools regarding issues with any tools or equipment purchased or supplied through the Mopar tool and equipment program.

Service Procedure

A. Inspect for External Fuel Pump Relay

- Open hood.

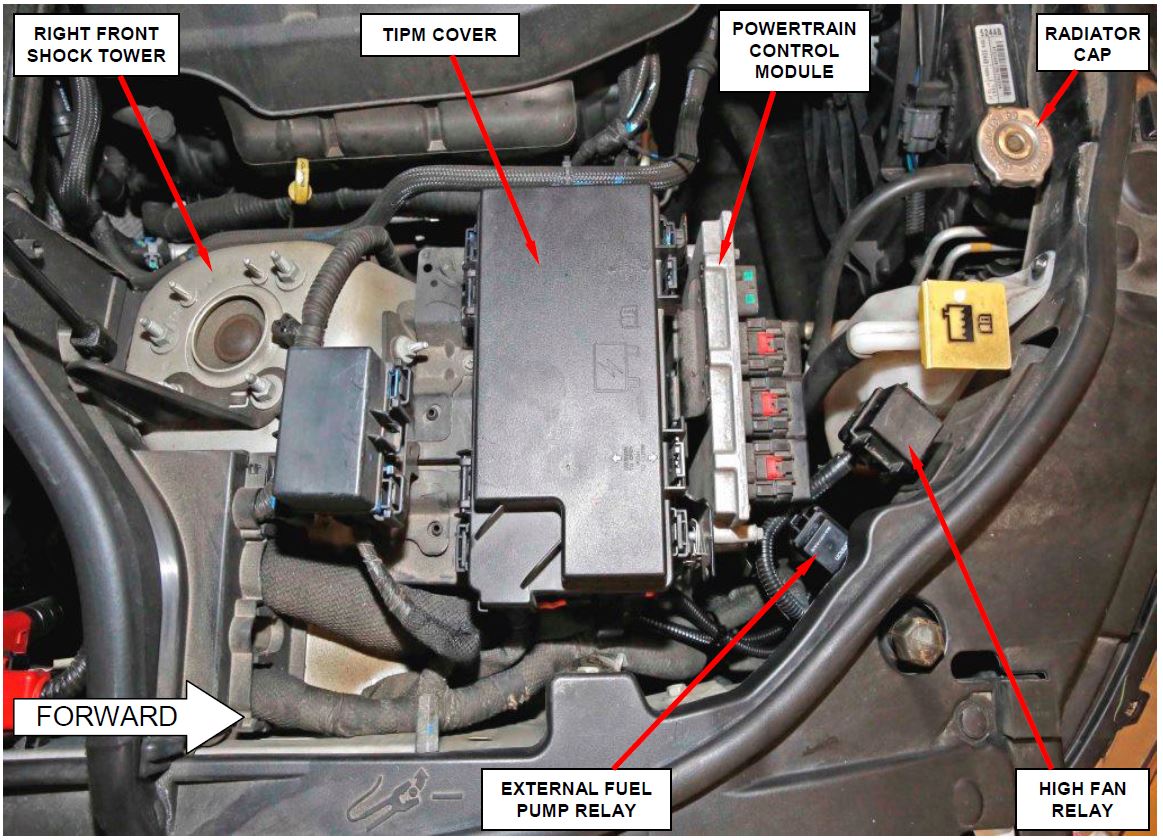

- Inspect for an external fuel pump relay (Figure 1):

- If there is an external fuel pump relay installed, no further action is required. Return the vehicle to the customer.

- If there is no external fuel pump relay, continue with Section B. Install External Fuel Pump Relay.

Figure 1 – Inspect for External Fuel Pump Relay

B. Install External Fuel Pump Relay

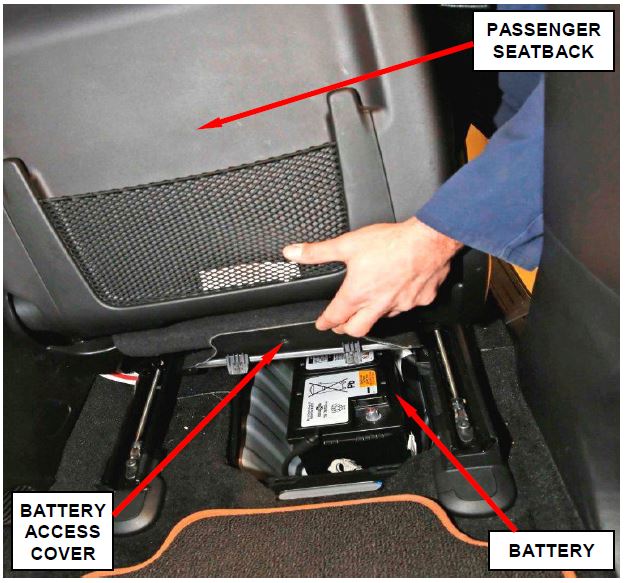

- Position the passenger seat fully forward.

- Open the battery access cover located under the passenger front seat and disconnect the negative battery cable (Figure 2).

Figure 2 – Battery Access

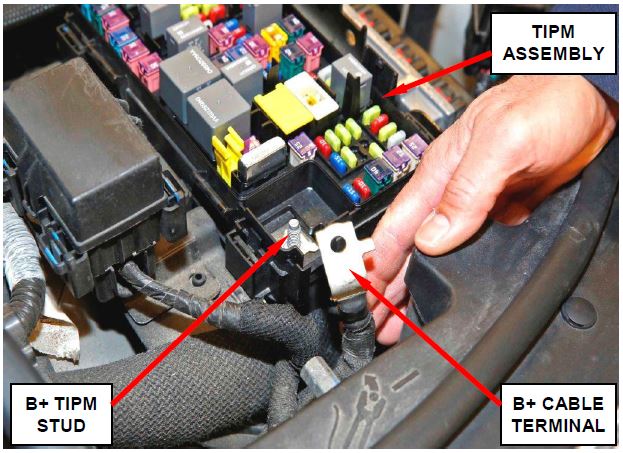

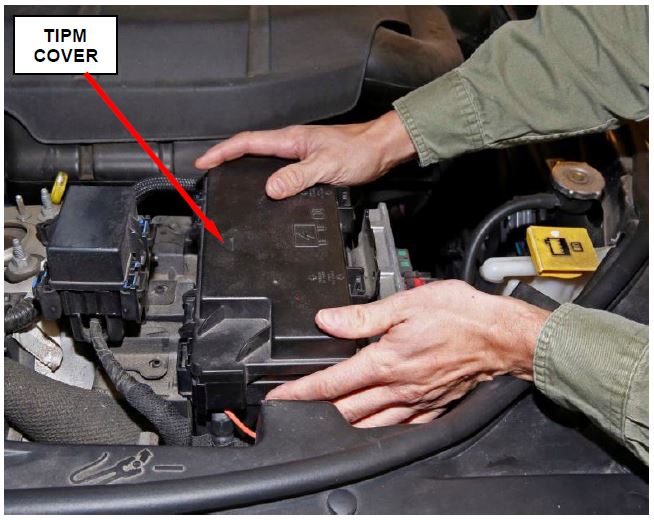

- Remove and save the Totally Integrated Power Module (TIPM) access cover.

- Remove and save the B+ cable terminal retaining nut.

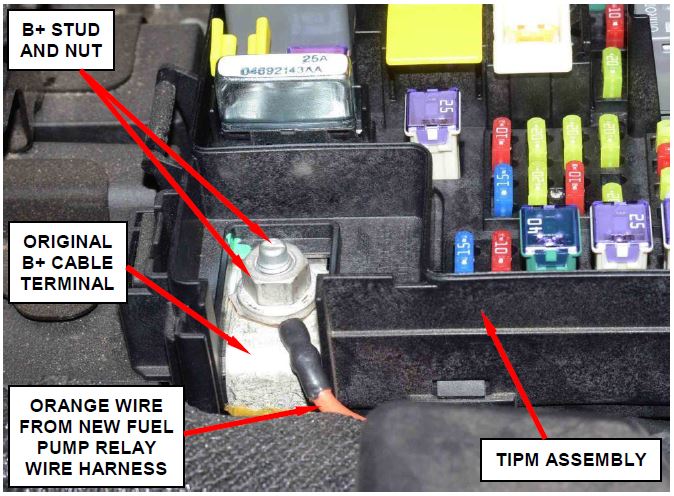

- Carefully separate the B+ cable terminal from the B+ TIPM stud (Figure 3).

Figure 3 – B+ Cable Terminal

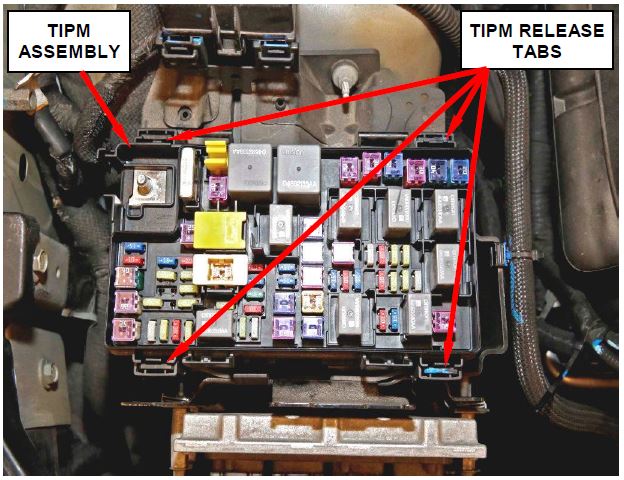

Figure 4 – TIPM Release Tabs

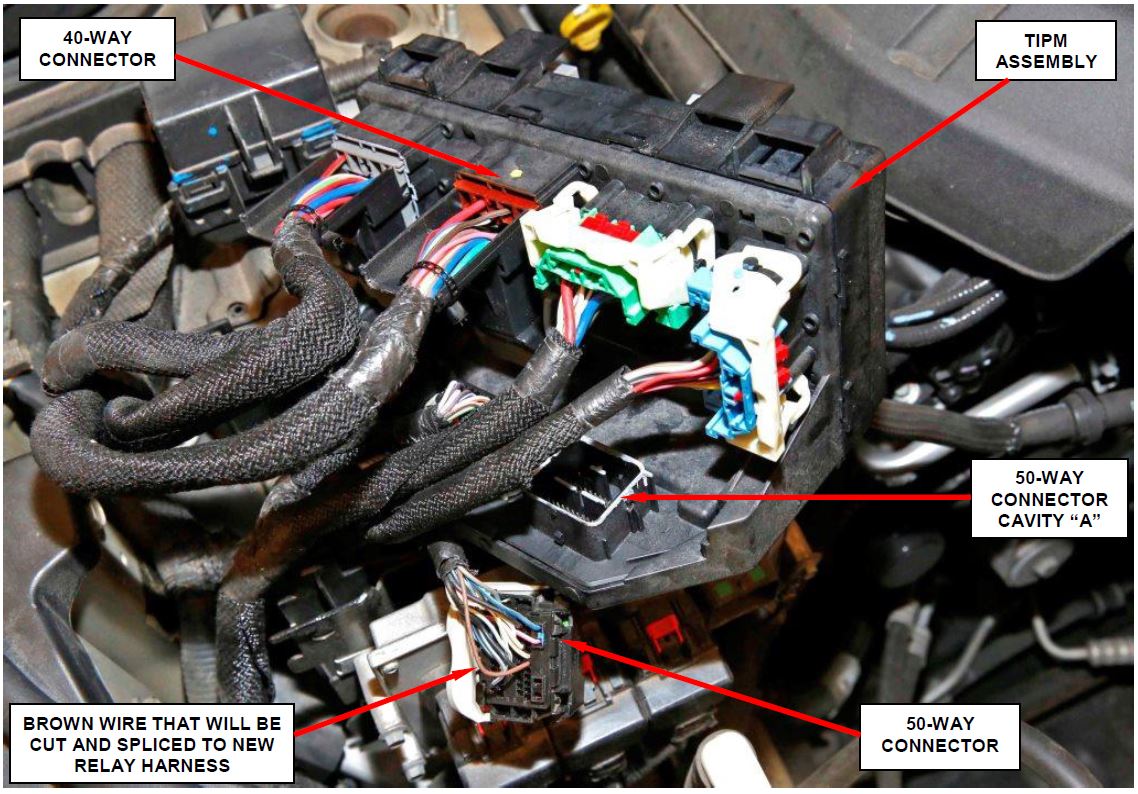

- Unplug the 50-way electrical connector from the bottom of the TIPM (Cavity “A”) (Figure 5).

Figure 5 – TIPM 50-Way Electrical Connector

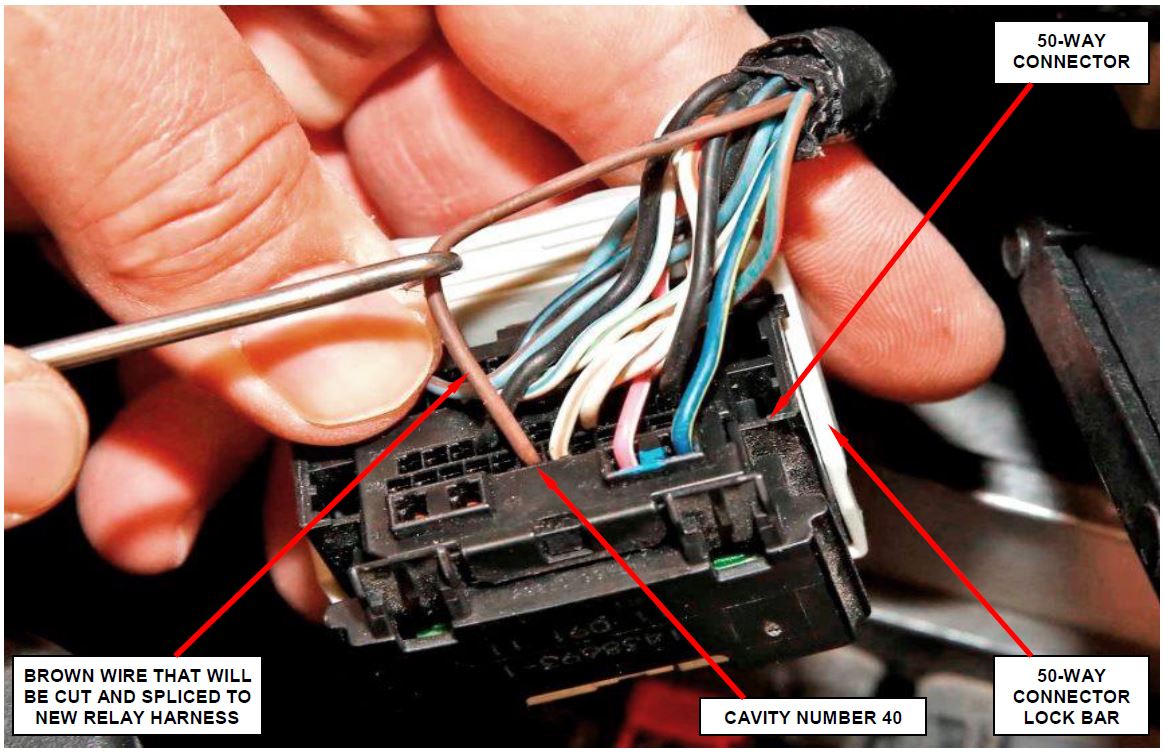

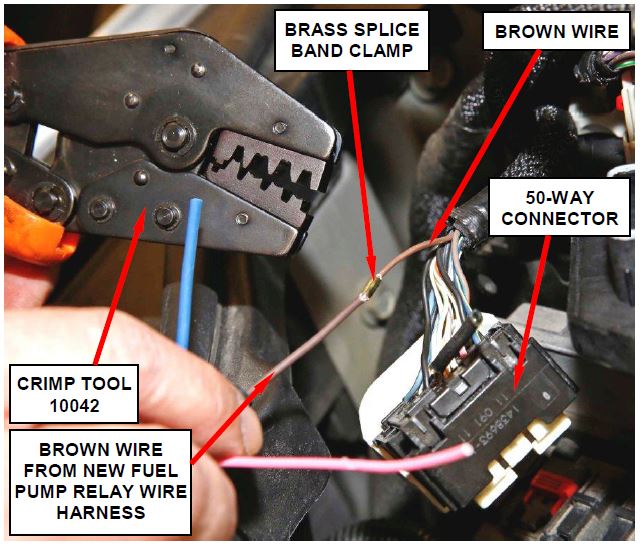

- Locate the brown wire in cavity number 40 of the 50-way electrical connector (Figure 6).

Figure 6 – Locate Brown Wire in 50-Way Connector

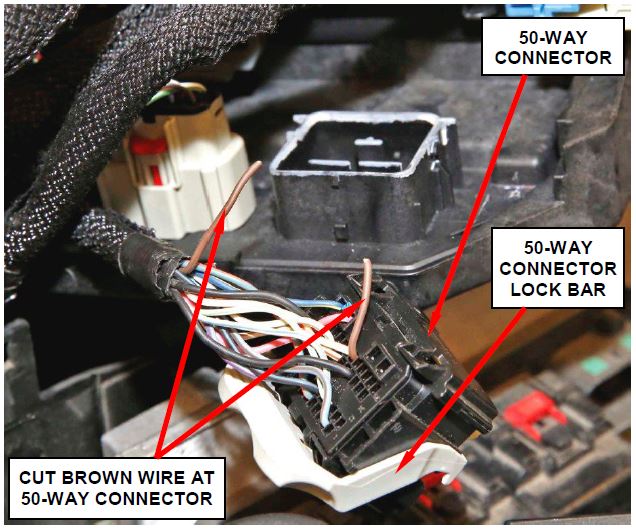

- Cut the brown wire one inch (25 mm) from the 50-way electrical connector (Figure 7).

Figure 7 – Cut the Brown Wire One Inch From Connector

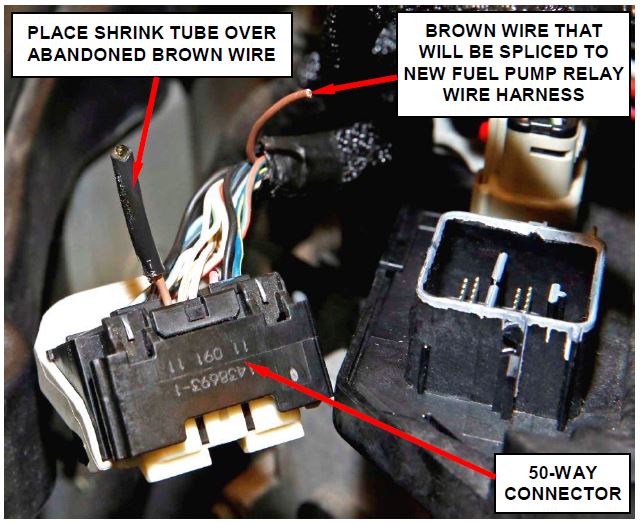

- Install shrink tube to the connector side brown wire to insulate the wire end. This wire will no longer be used (Figure 8).

Figure 8 – Insulate Brown Abandoned Wire

- Using the following procedure, splice the brown wire on the wire harness to the brown wire on the new fuel pump relay harness:

a. Strip approximately ½ inch (13 mm) of insulation from the end of the brown wire on the new fuel pump relay wire and the original brown wire.

b. Place a piece of black shrink tube, provided in the repair kit, over the cut brown wire.

c. Using the supplied brass splice band clamp and crimp tool 10042, crimp the brown wire on the wire harness side to the brown wire on the new fuel pump relay harness (Figure 9).

d. Solder the brass splice band clamp with rosin core solder.

e. Slide the shrink tube evenly over the soldered brass splice and apply heat to the shrink tube until glue comes out of both ends of the shrink tube.

Figure 9 – Crimp and Solder Brown Wires

- Carefully plug the 50-way electrical connector into the bottom of the TIPM.

CAUTION: Be sure that the 50-way connector lock bar is fully engaged.

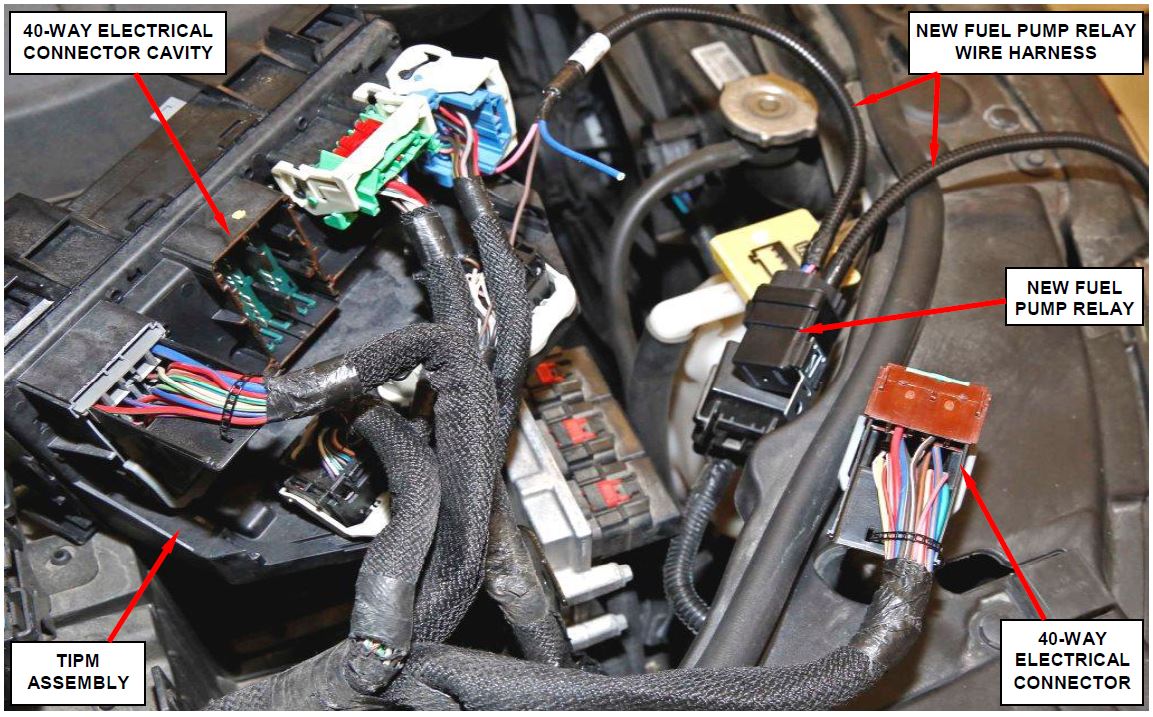

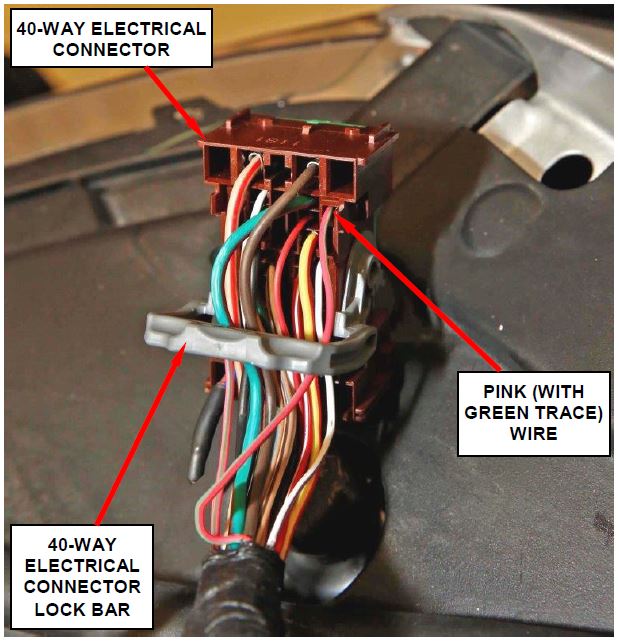

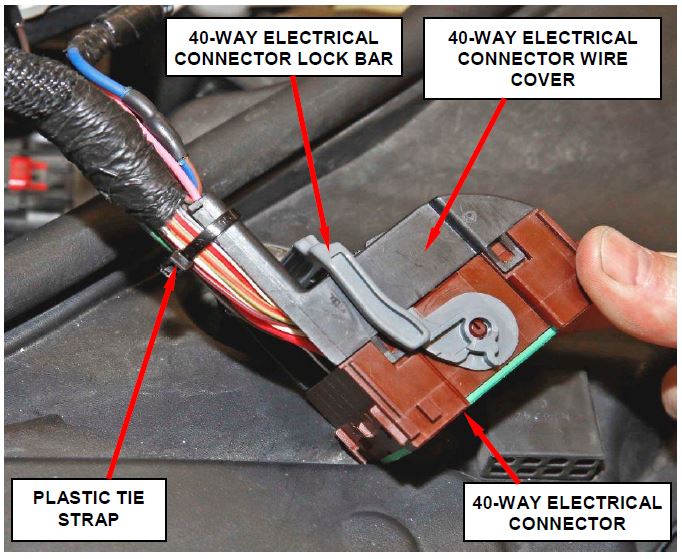

- Unplug the 40-way electrical connector located on the bottom side of the TIPM (Figure 10).

Figure 10 – TIPM 40-Way Electrical Connector

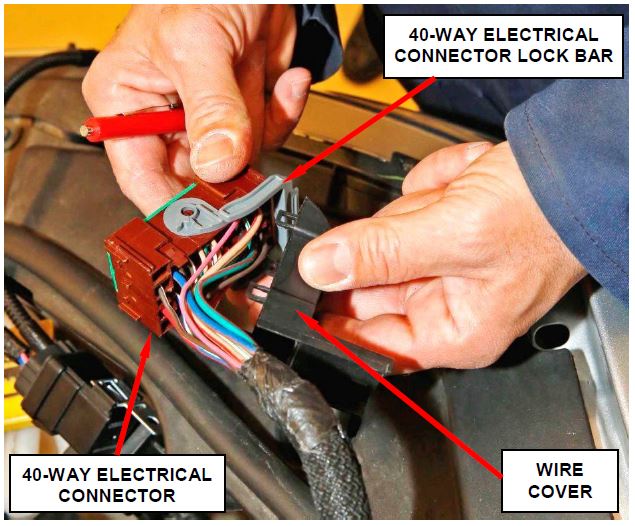

- Carefully remove and save the 40-way electrical connector wire cover located on the wire side of the connector (Figure 11).

NOTE: The plastic tie strap that holds the wire harness to the wire cover must be cut off and discarded (Figure 10).

Figure 11 – 40-Way Electrical Connector Wire Cover

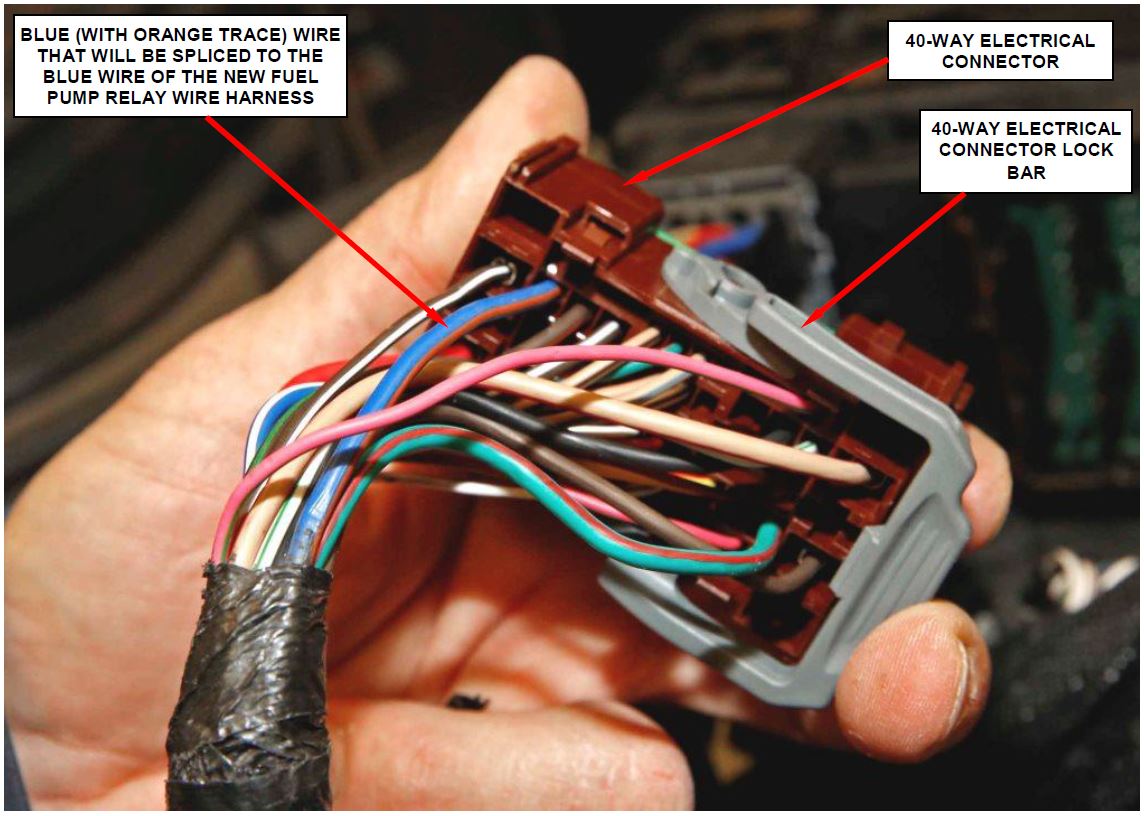

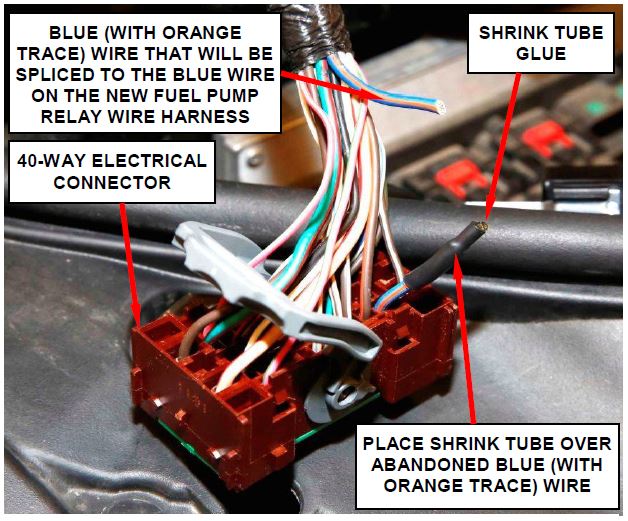

- Locate the blue (with an orange trace) wire in the 40-way electrical connector (Figure 12).

Figure 12 – Locate Blue with Orange Trace Wire in 40-Way Connector

- Cut the blue (with an orange trace) wire one inch (25 mm) from the 40-way electrical connector (Figure 13).

- Install shrink tube to the connector side blue (with an orange trace) wire to insulate the wire end. This wire will no longer be used (Figure 13).

Figure 13 – Cut the Blue (with Orange Trace) Wire

- Using the following procedure, splice the blue (with an orange trace) wire on the wire harness to the blue wire on the new fuel pump relay harness:

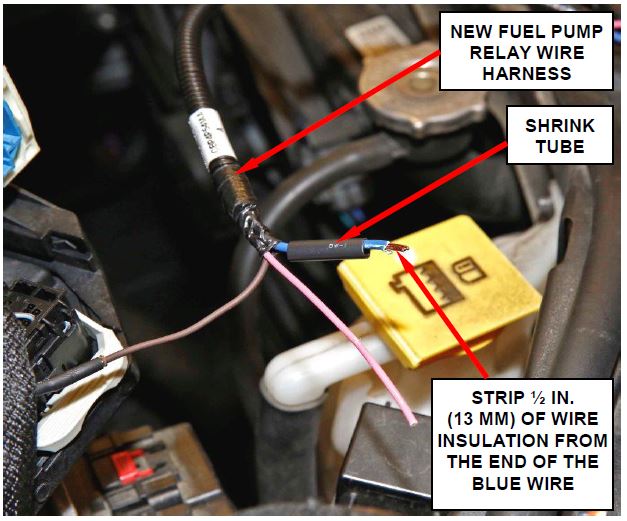

a. Strip approximately ½ inch (13 mm) of insulation from the end of the blue wire on the new fuel pump relay wire and the original blue (with an orange trace) wire (Figure 14).

b. Place the black shrink tube provided in the repair kit over the cut wire (Figure 14).

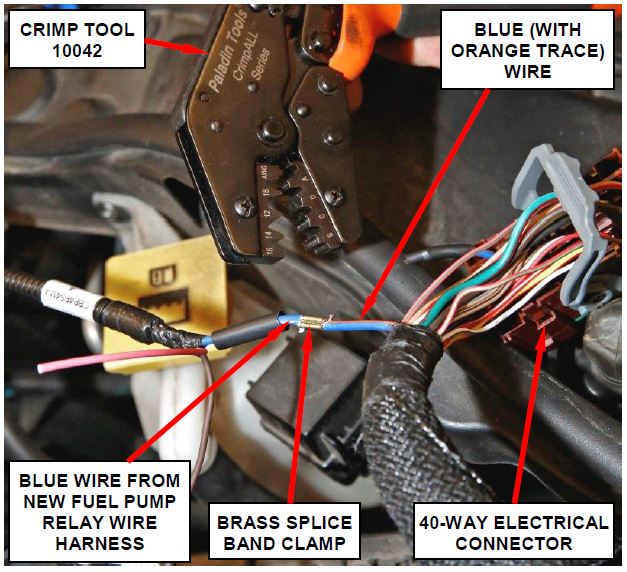

c. Using the supplied brass splice band clamps and crimp tool 10042, crimp the blue wire (with orange trace) on the wire harness side to the blue wire on the fuel pump relay wire harness (Figure 15).

d. Solder the brass splice band clamp with rosin core solder (Figure 15).

e. Slide the shrink tube evenly over the soldered brass splice band clamp and apply heat to the shrink tube until glue comes out of both ends of the shrink tube.

Figure 14 – Strip Wire and Install Shrink Tube

Figure 15 – Crimp and Solder Blue Wire to Blue Wire (with Orange Trace)

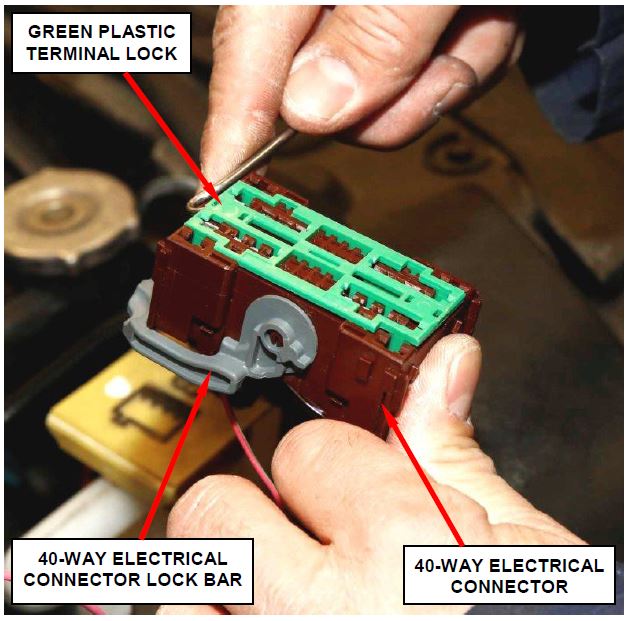

- Remove and save the 40-way electrical connector green plastic terminal lock (Figure 16).

Figure 16 – Green Connector Lock

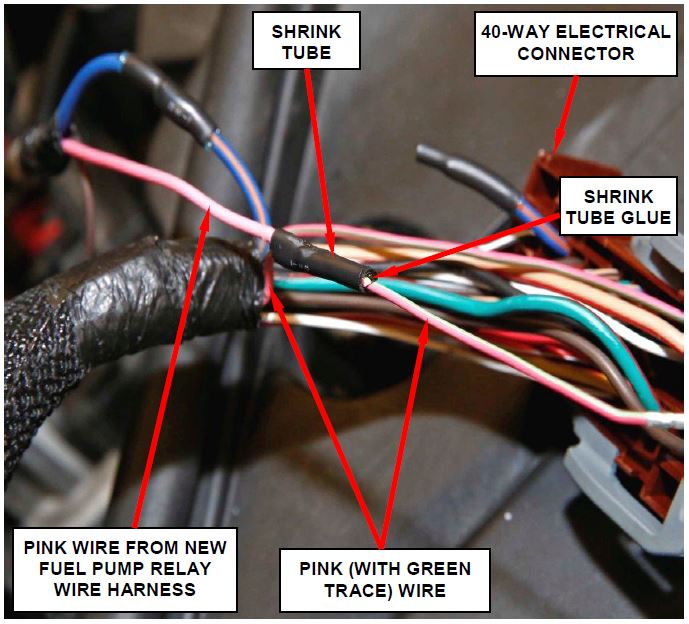

- Locate the pink (with green trace) wire in cavity 38 of the 40-way electrical connector (Figure 17).

Figure 17 – Pink (with Green Tracer) Wire Location

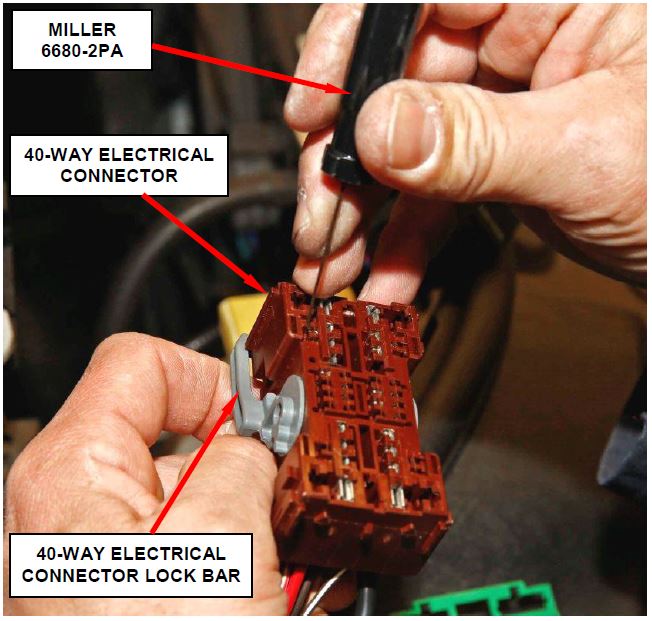

- Carefully remove the pink (with a green trace) from the 40-way connector (Figure 18).

NOTE: Use Miller Tool 6680-2PA terminal pick, or equivalent, to remove the wire terminal from the 40-way electrical connector.

Figure 18 – Remove Pink (with Green Trace) wire from 40-Way Connector

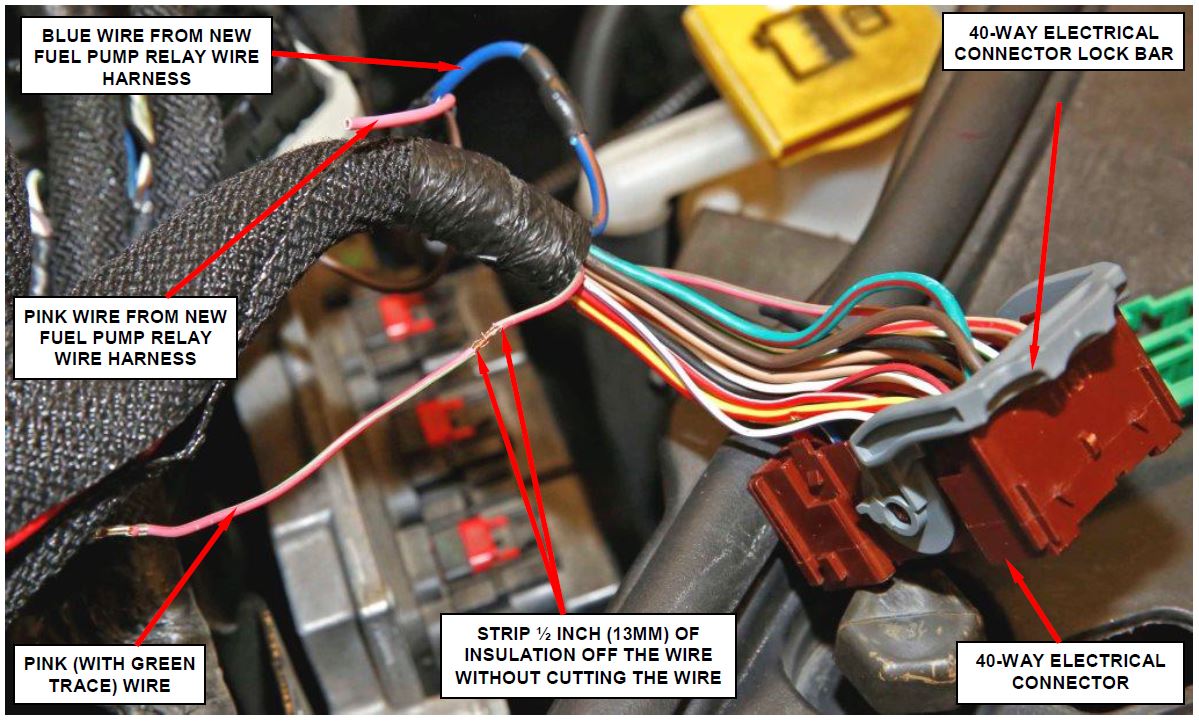

- Strip approximately ½ inch (13 mm) of insulation off the pink (with green trace) wire without cutting the wire (Figure 19).

Figure 19 – Remove Insulation without Cutting the Wire

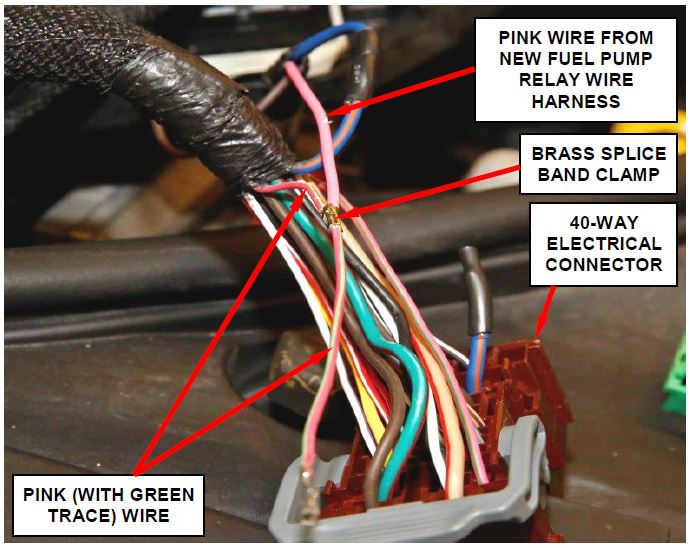

- Using the following procedure, splice the pink (with a green trace) wire to the pink wire on the new fuel pump relay harness:

a. Strip approximately ¾ inch (20 mm) of insulation from the end of the pink wire on the new fuel pump relay wire.

b. Wrap the pink wire from the new fuel pump relay wire harness around the pink (with green trace) wire at the location the insulation was removed (Figure 20).

c. Using the supplied brass splice band clamp and crimp tool 10042, crimp the fuel pump wire harness pink wire to the pink (with a green trace) wire on the vehicle wire harness (Figure 20).

d. Solder the brass splice band clamp with rosin core solder.

e. Slide the shrink tube evenly over the soldered brass splice band clamp and apply heat to the shrink tube until glue comes out of both ends of the shrink tube (Figure 21).

Figure 20 – Crimp and Solder Pink Wire to Pink (with Green Trace) Wire

Figure 21 – Install Shrink Tube

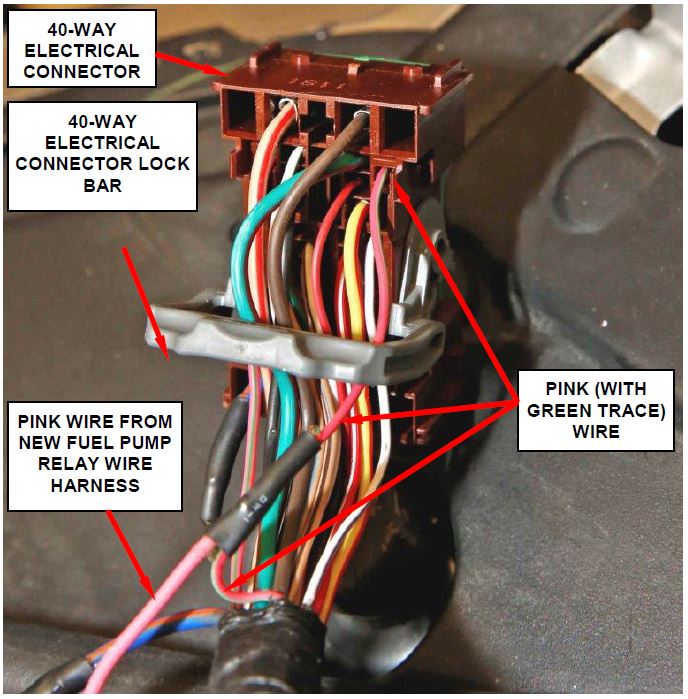

- Carefully install the wire terminal for the pink (with green trace) wire back into the same cavity (cavity 38) in the 40-way electrical connector that it was removed from (Figure 22).

Figure 22 – Install Pink (with Green Trace) Wire Terminal into the same cavity on the 40-Way Connector from which it was removed

- Install the 40-way electrical connector green plastic terminal lock (Figure 16).

- Install the 40-way electrical connector wire cover.

- Install a plastic tie strap to hold the wire harness in place on the back side of the 40-way electrical connector (Figure 23).

Figure 23 – Install Back Cover and Tie Strap

- Plug the 40-way electrical connector into the bottom of the TIPM assembly.

CAUTION: Be sure the 40-way electrical connector lock bar is fully engaged.

- Snap the TIPM assembly back into the TIPM support bracket.

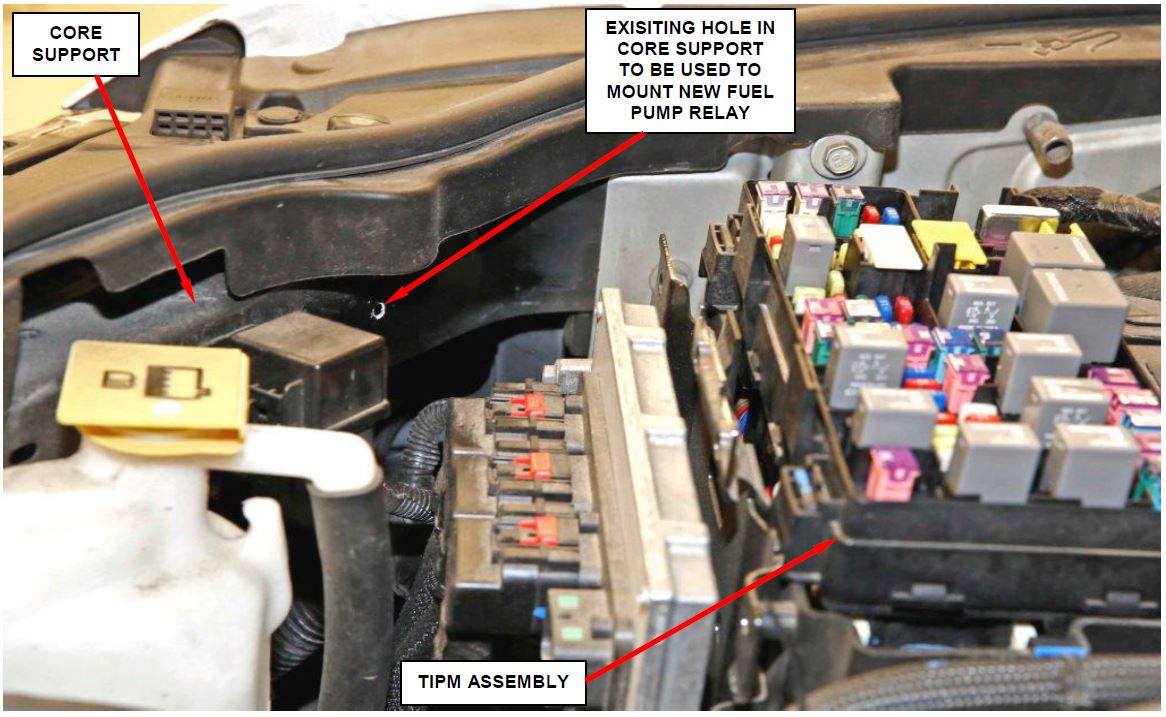

- Mount the new external fuel pump relay to the vehicle core support. Use the existing hole in the core support and the supplied plastic push pin (Figure 24).

Figure 24 – Mount New External Relay to Vehicle Core Support

- Connect the original B+ cable terminal to the TIPM B+ stud (Figure 25).

- Connect the wire eyelet on the orange wire of the new fuel pump relay wire harness to the TIPM B+ stud (Figure 25).

- Install the B+ cable terminal retaining nut. Tighten the nut to 14 ft. lbs. (19 N·m) (Figure 25).

Figure 25 – B+ Electrical Connection

- Push down on all the relays and fuses in the TIPM to ensure that they are all fully engaged.

- Using the provided plastic tie straps, secure the new fuel pump wire harness to the existing vehicle wire harness as required.

CAUTION: Be sure that the new fuel pump relay wire harness does not contact any sharp edges that may damage the new fuel pump relay wire harness.

- Carefully install the TIPM access cover (Figure 26).

Figure 26 – Install TIPM Cover

- Connect the negative battery cable to the negative battery terminal on the battery and close the battery access cover.

- Return the passenger seat to its original location.

- Return the vehicle to the customer.

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims submitted will be used by FCA to record recall service completions and provide dealer payments.

Use the following labor operation number and time allowance:

| Labor Operation Number | Time Allowance | |

|---|---|---|

| Inspect for external fuel pump relay | 08-R0-91-81 | 0.2 hours |

| Inspect and install external fuel pump relay | 08-R0-91-82 | 0.7 hours |

Add the cost of the recall parts package plus applicable dealer allowance to your claim.

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Enclosed with each owner letter is an Owner Notification postcard to allow owners to update our records if applicable.

Dealers are encouraged to consider alternative scheduling and servicing approaches for this recall. This repair does not require hoists or other full service facility special equipment and is a FCA Mobile Service approved repair.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

IMPORTANT SAFETY RECALL

R09 / NHTSA 15V-115

This notice applies to your vehicle (VIN: xxxxxxxxxxxxxxxxx).

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. Dear: (Name)

FCA has decided that a defect, which relates to motor vehicle safety, exists in certain 2012 and 2013 model year Dodge Durango and Jeep

Durango and Jeep Grand Cherokee vehicles.

Grand Cherokee vehicles.

| The problem is… | The Totally Integrated Power Module (TIPM) on your vehicle contains an internal fuel pump relay that could operate intermittently or fail without warning. An intermittent or failed fuel pump relay could cause the engine to stall while driving and cause a crash without warning. |

| What your dealer will do… | FCA will repair your vehicle free of charge. To do this, your dealer will install an external fuel pump relay. The work will take about one hour to complete. However, additional time may be necessary depending on service schedules. |

| What you must do to ensure your safety… | Simply contact your Chrysler , Jeep , Jeep , Dodge , Dodge or RAM or RAM dealer right away to schedule a service appointment. Ask the dealer to hold the parts for your vehicle or to order them before your appointment. Please bring this letter with you to your dealer. dealer right away to schedule a service appointment. Ask the dealer to hold the parts for your vehicle or to order them before your appointment. Please bring this letter with you to your dealer. |

| If you need help… | If you have questions or concerns which your dealer is unable to resolve, please contact the FCA Group Recall Assistance Center at either recalls.mopar.com or 1-800-853-1403. |

Please help us update our records by filling out the attached prepaid postcard if any of the conditions listed on the card apply to you or your vehicle. If you have further questions go to recalls.mopar.com.

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online or you can mail your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement. Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you’ve had previous repairs and/or reimbursement you may still need to have the recall repair performed on your vehicle.

If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to safercar.gov.

We’re sorry for any inconvenience, but we are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Services / Field Operations

FCA US LLC

Note to lessors receiving this recall: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

1500 Durango Grand Caravan for Chrysler Town & Country for Grand Cherokee" data-aawp-geotargeting="true">

Bestseller No. 1

1500 Durango Grand Caravan for Chrysler Town & Country for Grand Cherokee" data-aawp-geotargeting="true">

Bestseller No. 1

- 【Function】The fuel pump relay wiring kit functions as an automatic regulator, safety protector, circuit converter and switch. It can obtain a larger fuel supply on the basis of the conventional fuel system, ensure that the high-pressure fuel pump gets the required voltage, and prevent the overload of the electronic fuel pump from damaging the electrical system.

- 【Replaceable Part Number】Replaces 68269523AD 04727370AA 4727370AA CBWPR091AA CSZDV621AA CBP4P541AB.

- 【Compatibility】Compatible with Dodge

Durango 2011 2012 2013, with Dodge

Durango 2011 2012 2013, with Dodge Grand Caravan 2011,with Ram 1500 2011, with Chrysler

Grand Caravan 2011,with Ram 1500 2011, with Chrysler Town & Country 2011, with Jeep

Town & Country 2011, with Jeep Grand Cherokee 2011.

Grand Cherokee 2011. - 【Easy to install】Plug and play,The easy to install design allows the kit to be seamlessly matched to specific vehicle types.

- Compatible: This Fuel Pump Relay Wiring kit is compatible with a range of popular vehicle models, including Dodge Ram 1500, Durango, Grand Caravan, Chrysler Town & Country, and Jeep Grand Cherokee, ensuring a perfect fit.

- Replace OE: Designed to replace OE (Original Equipment) part numbers such as 68269523AD,CBWPR091AA, CSZDV621AA, CBP4P541AB, 04727370AA, and 4727370AA, this kit offers a cost-effective alternative to dealership replacements.

- High Quality: Crafted with precision and built to last, our Fuel Pump Relay Wiring Kit is made from top-quality materials to ensure reliability and longevity. It meets or exceeds OEM specifications.

- Function: It can obtain a larger fuel supply on the basis of the conventional fuel system, ensure that the high-pressure fuel pump gets the required voltage, and prevent the overload of the electronic fuel pump from damaging the electrical system.

- Package Includes:1PC Fuel Pump Relay Wiring,1PC Relay Block,4Pcs Heat Shrink Tube,4Pcs Cable Clip,3Pcs Cable Tie

- Compatible with: Dodge Durango 2011-2013; Chrysler Town Country 2011; Dodge Grand Caravan 2011; Grand Cherokee 2011; Ram 1500 2011

- Replacement Part Number: CBWPR091AA; CSZDV621AA; CBP4P541AB; 68269523AD; 04727370AA; 4727370AA

- Reliable Performance: Rely on our fuel pump relay wiring kit to ensure your fuel pump runs smoothly and reliably when you need it

- Reliable Fuel Supply: Our fuel pump relay wiring kits ensure a consistent and reliable connection to keep your vehicle's fuel system intact

- Package Included: One Fuel Pump Relay Wiring Kit

- Fitment:fit for Chrysler Town and Country 2008-2016, fit for VW Routan 2011-2012, fit for Jeep Grand Cherokee 2011-2013, fit for Wrangler 2007-2016, fit for Liberty 2007-2012, fit for Grand Caravan 2008-2016, fit for Dodge Ram 1500 2500 3500 2011-2012, fit for Durango 2011-2013, fit for Journey 2009-2010, fit for Nitro 2007-2011, fit for Grand Caravan 2008-2016.

- Function:When the fuel pump of your vehicle is defective, can you use this TIPM bypass cable to bypass the defective TIPM relay and supply power to the fuel pump from another power source, which will perfectly solve the problem of no start or battery depletion of Dodge/Jeep/Chrysler/Volkswagen.

- How we solve the problem:No skills are required if you can open the fuse box and your vehicle will be running again in less than 5 minutes.If you have a repair facility, having cables on hand can quickly test TIPM or fuel pump relay problems in Dodge/Chrysler/Jeep/Volkswagen vehicles without starting or battery drain symptoms.

- Features:The 400-strand silicone-jacketed wire allows these cables to be routed easily within the confines of the fuse box without worrying about pinching wires or straining the fuse socket , We use the highest quality 14 AWG silicone, high temperature (200c), for the best cables on the market.

- About us:Communication is the best way to solve the problem. If you have any question after purchasing, please contact us in time, before opening return or case.

- TIPM Bypass Cable Fits for: 2007-2016 Dodge/Jeep/Chrysler/VW, more information please check the description below.

- Fuel Pump Relay Kit Function: This TIPM bypass cable allow you to bypass the defective TIPM relay to provide power to the fuel pump from an another power source (like the M37 run/start fuse slot), which means your vehicle can still be started even with a defective fuel pump, perfectly solve the Dodge/Jeep/Chrysler/VW no start or dead battery problems.

- Well Performance: Made of high-quality material, continuous Relay Bypass Wire are made to meet the standard 14 AWG wire/20 amps, which provide safety as well as quality.

- Easy Installation: No special skill required.

- Package Includes: 1 piece of bypass cables , 5 pieces of fuse adapter and 1 piece Fuse Fuse Puller

- Fitment: Fit for Chrysler Town and Country 2008-2016 ; Fit for Jeep Grand Cherokee 2011-2013 ; Fit for Dodge Grand Caravan 2008-2016 ; Fit for Dodge Ram 1500, 2500, or 3500 2011-2012 ; Fit for Dodge Durango 2011-2013 ; Fit for Jeep Wrangler 2007-2016 ; Fit for Dodge Journey 2009-2010 ; Fit for Jeep Liberty 2007-2012 ; Fit for VW Routa 2011-2012 ; Fit for Dodge Nitro 2007-2011 .

- TIPM and Fuel Relay bypass cables are a simple way to test or bypass faulty fuel pump relay problems on many 2004 and newer for Dodge/for Jeep/for Chrysler vehicles. If your vehicle acts like it's out of gas and/or your fuel pump continues pumping after turning the vehicle off (draining your battery), you likely have a faulty fuel pump relay.

- Our TIPM Fuel Pump Relay Bypass works with most 2004-2016 Dodge Jeep Chrysler and some VW models. We provide the best cable on the market using the highest quality 14 AWG Silicone, High Temp (200c). Our 400 Strand Silicon Jacket wire allows these cables to route easily within the confines of your fuse box without having to worry about pinched wires or straining your fuse sockets. Our 14 AWG wire is upgraded to provide 20 amp capacity. Don't settle for a hacked solution to save a dollar or two.

- Our cable bypasses the TIPM/fuel pump relay saving hundreds of dollars in repair or replacement! No skills are necessary if you can open your fuse box and you'll have your vehicle running again in less than 5 minutes.

- [Premium Quality Assurance] Our automotive parts are crafted from top-tier materials and manufactured under stringent quality control protocols. Each item undergoes rigorous inspections and multiple tests to ensure reliability and performance. We are committed to delivering products that meet and exceed industry standards, providing you with the highest level of satisfaction.

- Emergency One-Pack Solution – Immediate Replacement in Case of Critical Relay Failure

- OEM Same Specs – Compatible with Mopar 68083380AA Terminal Layout and Load Capacity

- Prevents Overheating – Fits Radiator Fan Operation on Jeep Grand Cherokee (2014-2020)

- 35A High Efficiency Switch – Fits Fuel Pump Needs on Dodge Challenger (2015-2023)

- Compact SPST Design – Fits Factory Relay Box on Chrysler Pacifica (2017-2022)

- Troubleshoot: TIPM and Fuel Relay bypass cables are a simple way to test or bypass faulty fuel pump relay problems on many 2004 and newer Dodge/Je-ep/Chrysler/VW vehicles. If your vehicle acts like it's out of gas and/or your fuel pump continues pumping after turning the vehicle off (draining your battery), you likely have a faulty fuel pump relay

- Superior Quality: TIPM fuse bypass made from high quality materials, good bending performance, melting resistance and excellent electrical conductivity. Continuous cables are custom made (14 AWG wire, 20 amps), which are more thick and safe

- Simple Solution: The Fuel Relay bypass cables work by providing power to the fuel pump from an alternate power source (the M37 run/start fuse slot), which permits the vehicle to start when a defective fuel pump relay is present. You simply need to plug their cable into two fuse slots to resolve "crank no start" issues or dead batteries due to a stuck on relay

- Compatible Model: Compatible with Chrysler Town and Country 2008-2016; Compatible with VW Routan 2009-2014; Compatible with Je-ep Grand Cherokee 2011-2013; Compatible with Wrangler 2007-2018; Compatible with Liberty 2007-2012; Compatible with Grand Caravan 2008-2020; Compatible with Dodge Ram 1500 2500 3500 2011-2012; Compatible with Durango 2011-2013; Compatible with Journey 2009-2010; Compatible with Nitro 2007-2011, etc.

- Package Includes: 2Pcs TIPM bypass cable 8PCS 20A fuse and 2PCS 10A fuse. Our product is identified by the part number CBWPR091AA

- ➤Part number : Designed to replace OE part numbers such as 68269523AD,CBWPR091AA, CSZDV621AA, CBP4P541AB, 04727370AA, and 4727370AA,Please Be Very Careful to Check Our Photos, Make Sure The Photos Showed Is The Same as You Wanted.

- ➤Fuel Pump Relay Wiring Kit Fit for : This Fuel Pump Relay Wiring kit is fit for a range of popular vehicle models, including Dodge Ram 1500, Durango, Grand Caravan, Chrysler Town & Country, and Jeep Grand Cherokee, ensuring a perfect fit.

- ➤High quality :Made of high quality material, silver-plated contacts, this fuel pump relay wiring is anti-corrosion, solid, durable and has a long service life.

- ➤Packing :Fuel Pump Relay Wiring Kit 1 Relay, Fuel Pump 1 Harness, Wiring 3 Tube, Shrink 3 Crimp, Brass 1 Pin, Push 3 Strap, Plastic Tie

- ➤Warranty: For any reason, if you are not satisfied with Fuel Pump Relay Wiring Kit, please contact us directly. We offer half-year warranty, 100% satisfaction guarantee.

- Fit for Dodge Grand Caravan 2008-2016 ,Ram 1500 2011-2012,Ram 2500 2011-2012,Ram 3500 2011-2012,Durango 2011-2013 ,Journey 2009-2010 ,Nitro 2007-2011

- Fit for Jeep Wrangler 2007-2016 , for Jeep Liberty 2007-2012, for Jeep Grand Cherokee 2011-2013

- Fit for VW Routan 2011-2012, for Chrysler Town and Country 2008-2016

- Package Includes:1pc Fuel Pump Relay Bypass Cable Kit.You will get as pictured!

- Wish this high-quality aftermarket product kit would bring you a good experience.If there is any problem,please feel free to contact us

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.