| “This site contains affiliate links for which OEMDTC may be compensated” |

January 11, 2018

Fuel Line Separation may Cause Fire

If the fuel line separates, the engine may stall, increasing the risk of a crash. In addition, a fuel line separation increases the risk of an engine compartment fire and injury.

NHTSA Campaign Number: 18V048

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components FUEL SYSTEM, GASOLINE

Potential Number of Units Affected 1,242

Summary

Chrysler (FCA US LLC) is recalling certain 2018 Jeep

(FCA US LLC) is recalling certain 2018 Jeep Grand Cherokee Trackhawk vehicles equipped with a 6.2L Supercharged Engine. The fuel line may separate.

Grand Cherokee Trackhawk vehicles equipped with a 6.2L Supercharged Engine. The fuel line may separate.

Remedy

Chrysler will notify owners, and dealers will inspect and, as necessary, replace the fuel line, free of charge. The recall began February 23, 2018. Owners may contact Chrysler

will notify owners, and dealers will inspect and, as necessary, replace the fuel line, free of charge. The recall began February 23, 2018. Owners may contact Chrysler customer service at 1-800-853-1403. Chrysler

customer service at 1-800-853-1403. Chrysler ’s number for this recall is U02.

’s number for this recall is U02.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

February 2018

Dealer Service Instructions for:

Safety Recall U02 / NHTSA 18V-048 Fuel Supply Jumper Tube

Models

| 2018 | (WK) | Jeep ® Grand Cherokee Trackhawk ® Grand Cherokee Trackhawk |

NOTE: This recall applies only to the above vehicles equipped with a 6.2L V8 supercharged engine (sales code ESD) built from October 11, 2017 through December 11, 2017 (MDH 101105 through 121117).

| IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. |

Subject

The fuel line on about 1,200 of the above vehicles could separate resulting in an engine stall and/or a potential engine compartment fire. Either of these conditions could increase the likelihood of occupant injury, and an engine stall can cause a vehicle crash without prior warning.

Repair

The fuel supply jumper tube must be inspected and replaced as needed.

Alternate Transportation

Dealers should attempt to minimize customer inconvenience by placing the owner in a loaner vehicle if inspection determines that fuel supply jumper tube replacement is required and the vehicle must be held overnight.

Parts Information

| Description | Part Number |

|---|---|

| Jumper, Fuel Supply | 68305419AB |

Ordering of part number 68305419AB is restricted by VIN. Due to the small number of involved vehicles expected to require fuel supply jumper tube replacement, no parts will be distributed initially. The fuel supply jumper tube should be ordered only after inspection determines that repair is required. Very few vehicles are expected to require fuel supply jumper tube replacement.

NOTE: To order part number 68305419AB, dealer must send an email to Campaignteam@fcagroup.com provide the “VIN” the “Dealer Code” and state “vehicle inspection has determined that fuel supply jumper replacement is required”.

Save the packaging from new part to be reused for part return. Return of the old part is required for this campaign. Refer to the “Parts Return” section for part return instructions.

Parts Return

This recall part will be subject to parts return.

Part Return Requirements

Hold the part until the claim is paid. Once the claim is paid, go to the “Parts” tab and click on the “Return Material Utility” in “DealerCONNECT”. In the “Disposition” tab it will give a disposition of “Return”. In the “Tickets” tab under “UPS ground”, the claim will be listed. Select the ticket and follow the process to generate a “Part Return Document”, “UPS Shipping Label” and “UPS Receipt”. Place the failed part and the Part Return Document inside the box the new part came in. Attach the UPS Shipping label on the outside of the box and ship to:

Quality Engineering Center

2021 Executive Hills Blvd

Auburn Hills, MI 48326

Special Tools

The following special tools are required to perform this repair:

| wiTECH micro pod II |

| Laptop Computer |

| wiTECH Software |

Service Procedure

A. Fuel Supply Jumper Tube Inspection

- Open the engine compartment hood.

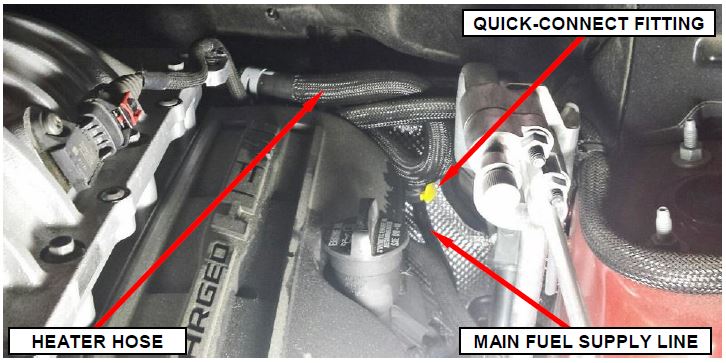

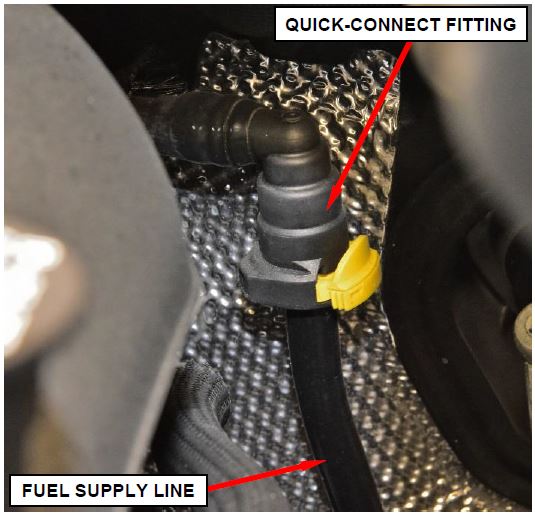

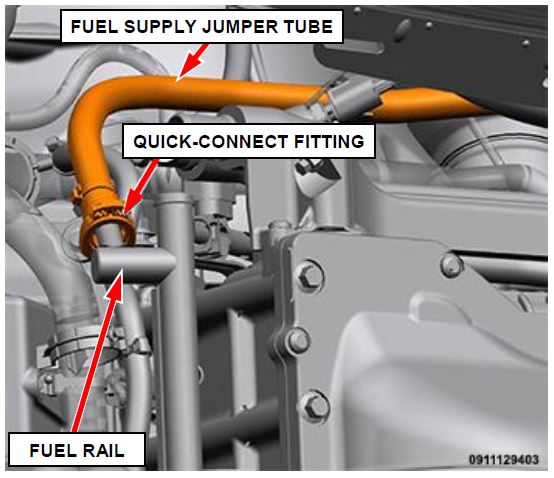

- Locate the fuel supply jumper quickconnect fitting near the cowl behind the left side of the engine (Figure 1).

Figure 1 – Fuel Supply Jumper Quick Connect Fitting

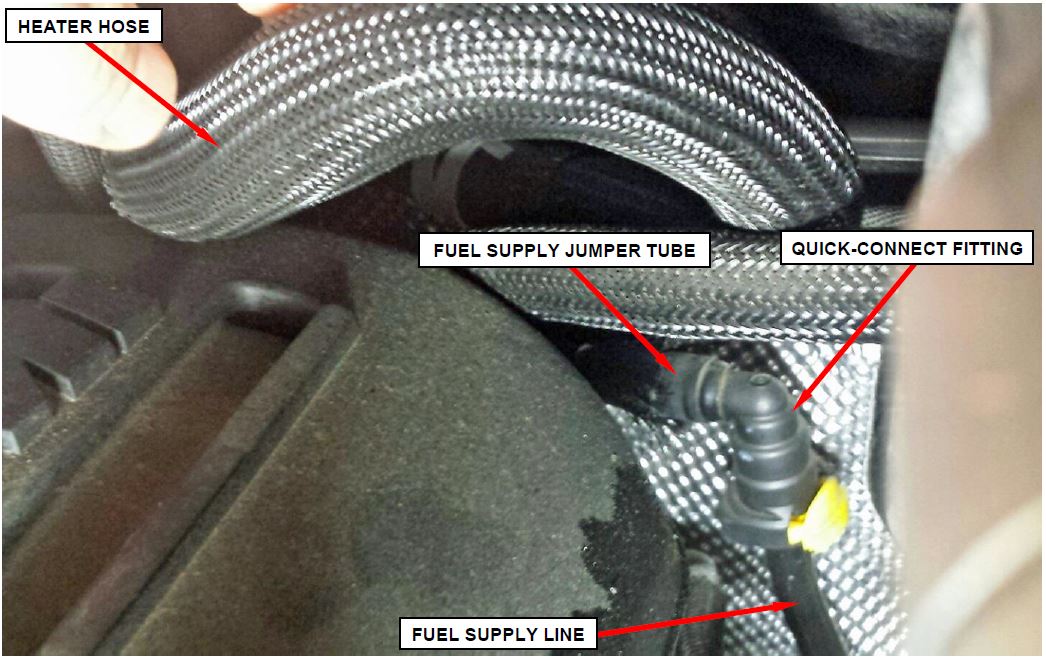

- Lift the heater hose out of the way in order to clearly view the area where the fuel supply jumper tube is attached to the quick-connect fitting (Figure 2).

Figure 2 – Fuel Supply Jumper Quick Connect Fitting

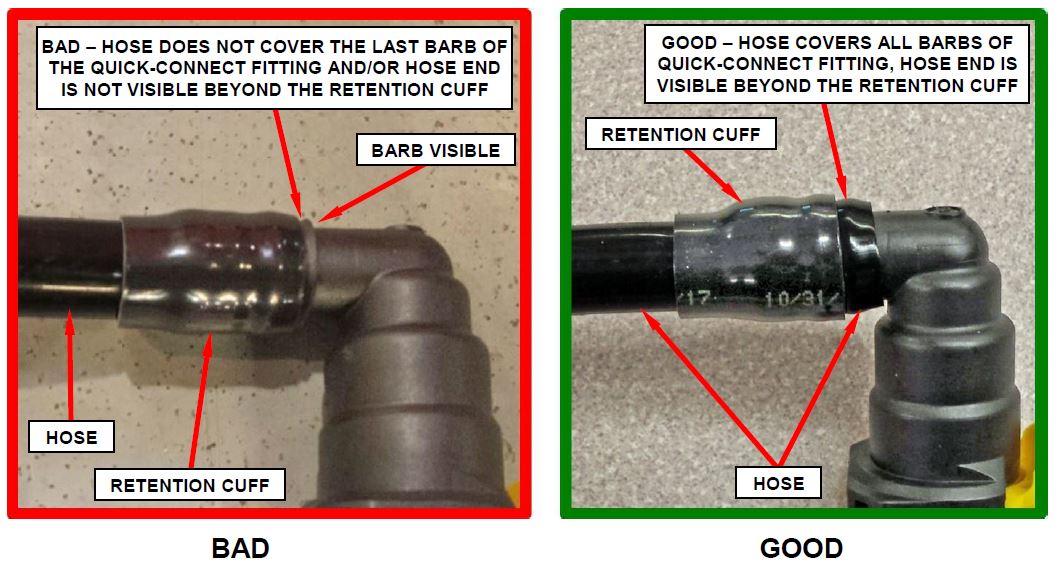

- Inspect the fuel supply jumper tube connection between the hose and quickconnect fitting. The hose must cover all the barbs on the quick connect fitting and hose end must be visible beyond the edge of the retention cuff. If the hose does not cover all barbs and/or is not visible beyond the edge of the retention cuff, then the fuel supply jumper tube must be replaced (Figure 3).

- GOOD – Fuel supply jumper tube hose covers all barbs of the quick-connect fitting and hose end is visible beyond the retention cuff. Position the heater hose back into its original location and close the engine compartment hood. This recall inspection is complete; claim the inspection LOP and return the vehicle to the customer.

- BAD – Fuel supply jumper tube hose does not cover all barbs of the quickconnect fitting and/or hose end is not visible beyond the retention cuff. The fuel supply jumper tube must be replaced.

Proceed to Section B. Fuel Supply Jumper Tube Replacement.

Figure 3 – Fuel Supply Jumper Tube – Inspect Hose Connection

NOTE: The opposite end of the fuel supply jumper tube where it attaches to the fuel rail on the right side of the engine does not require inspection.

B. Fuel Supply Jumper Tube Replacement

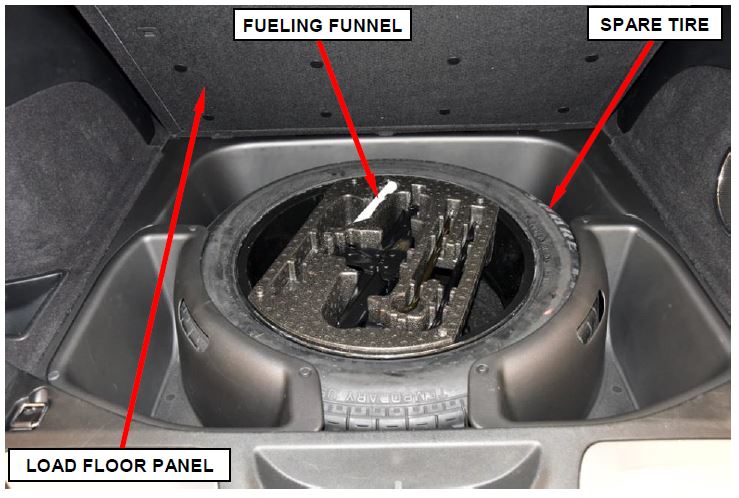

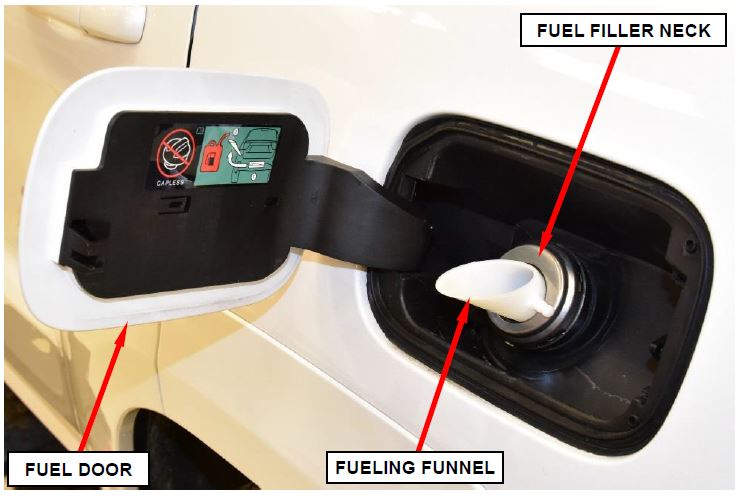

- Open the liftgate and raise the load floor panel, then locate the fueling funnel stored with the spare tire (Figure 4).

Figure 4 – Fueling Funnel Location

- Open the fuel door and insert the fueling funnel into the fuel filler neck to release any fuel tank pressure (Figure 5).

Figure 5 – Fuel Filler

- Take note of the customer’s preferred seat position then move the front passenger seat fully forward.

- Remove the battery compartment cover.

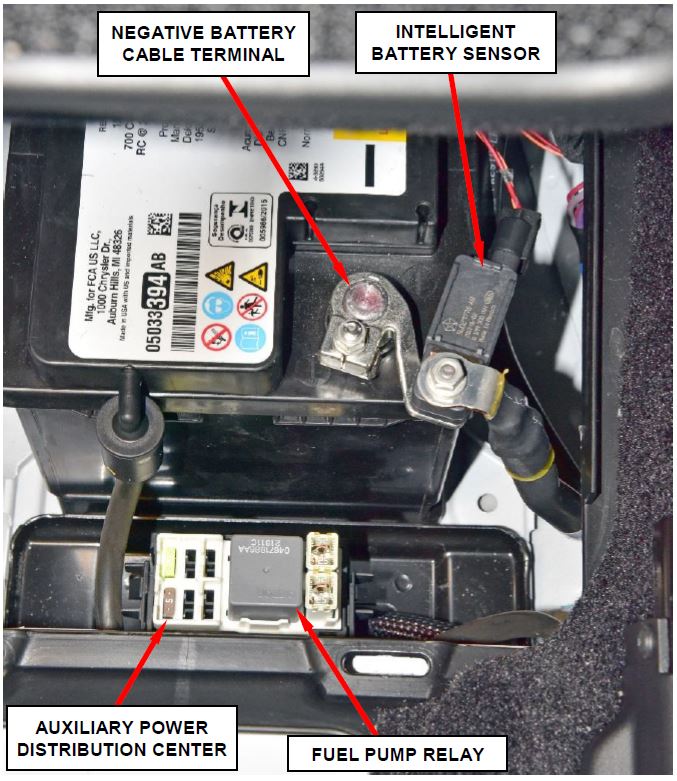

- Remove the fuel pump relay from the auxiliary power distribution center (Figure 6).

- Start and run the engine until it stalls.

- Attempt restarting the engine until it will no longer run.

Figure 6 – Fuel Pump Relay and Negative Battery Terminal

- Return the ignition push button to the “OFF” position.

- Disconnect and isolate the negative battery cable terminal from the vehicle battery. For vehicles equipped with a supplemental battery, also disconnect and isolate the negative battery cable terminal from the supplemental battery.

NOTE: If equipped with an Intelligent Battery Sensor (IBS), disconnect the IBS electrical connector first before disconnecting the negative battery cable terminal from the battery.

- Install the fuel pump relay in the auxiliary power distribution center (Figure 6).

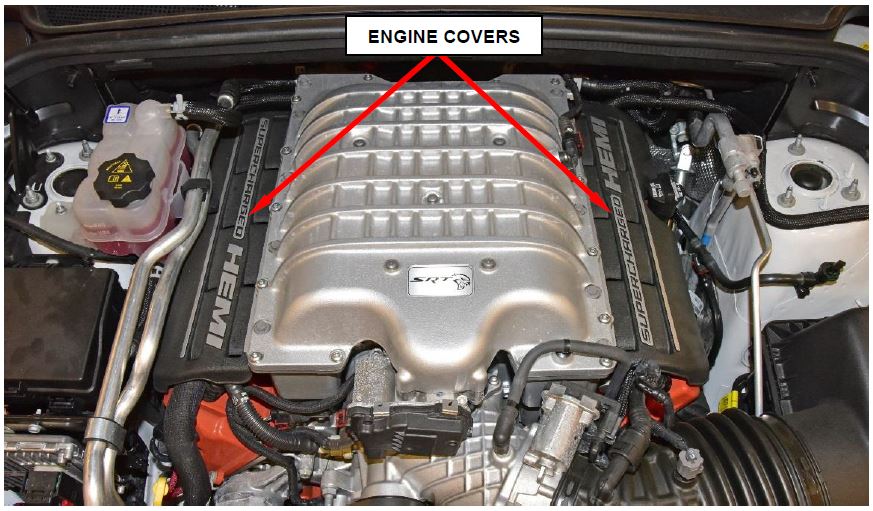

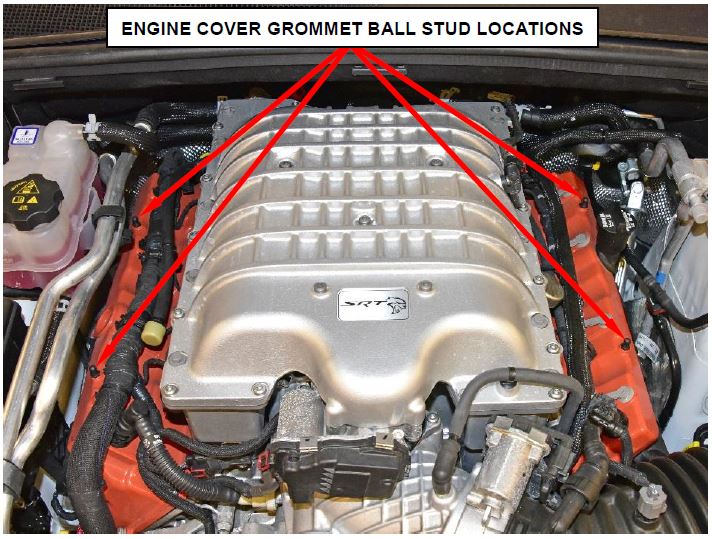

- Gently lift the engine covers vertically to release the engine cover grommets from the ball studs. Then remove the engine covers. The right-side engine cover will need to be slid forward toward the front of the engine to clear the coolant pipes (Figure 7).

Figure 7 – Engine Covers

- Place a rag or towel below the fuel supply jumper quick-connect fitting where it connects to the fuel supply line located near the cowl behind the left side of the engine (Figure 8).

WARNING: The catalytic converter is located directly below this fuel connection. To prevent a possible fire, ensure that the catalytic converter is not excessively hot before disconnecting this fuel connection.

Figure 8 – Fuel Supply Jumper Quick-Connect Fitting Left Side of Engine

- Perform the following steps to release the fuel supply jumper quickconnect fitting from the fuel supply line (Figure 9).

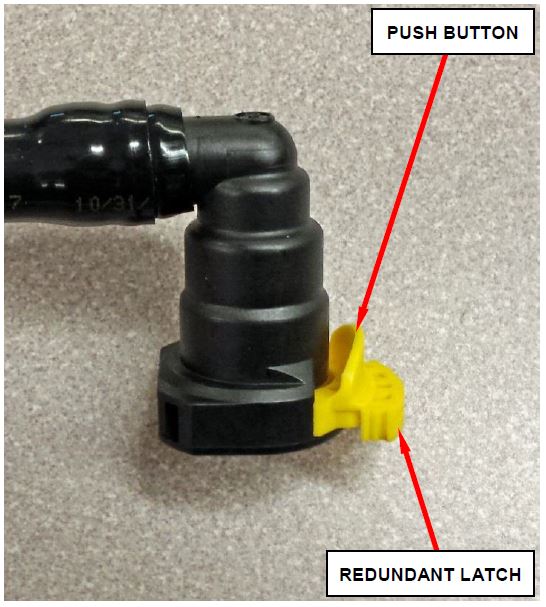

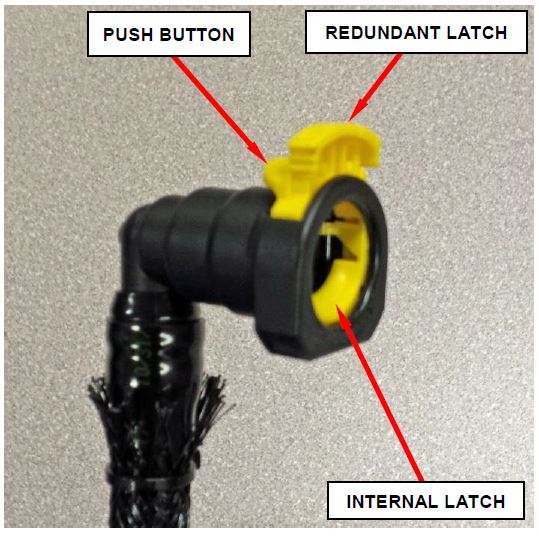

NOTE: This type of quick-connect fitting is equipped with a redundant latch and a single push button that releases the internal latch located in the quick-connect fitting. Special tools are not required for removal (Figure 10).

CAUTION: Do not pry or pull up on the push button as damage to the latch of the quick-connect fitting will occur.

a. Pull the redundant latch out away from the quick-connect fitting (Figure 10).

b. Press the push button to release the internal latch, then remove the quick-connect fitting from the fuel system component (Figure 10).

Figure 9 – Quick-Connect Fitting

Figure 10 – Quick-Connect Fitting

- Place a rag or towel below the fuel supply jumper quick-connect fitting where it connects to the fuel rail located near the cowl on the right side of the engine (Figure 11).

- Perform the procedure in Step 13 to release the fuel supply jumper quick-connect fitting from the fuel rail (Figure 11).

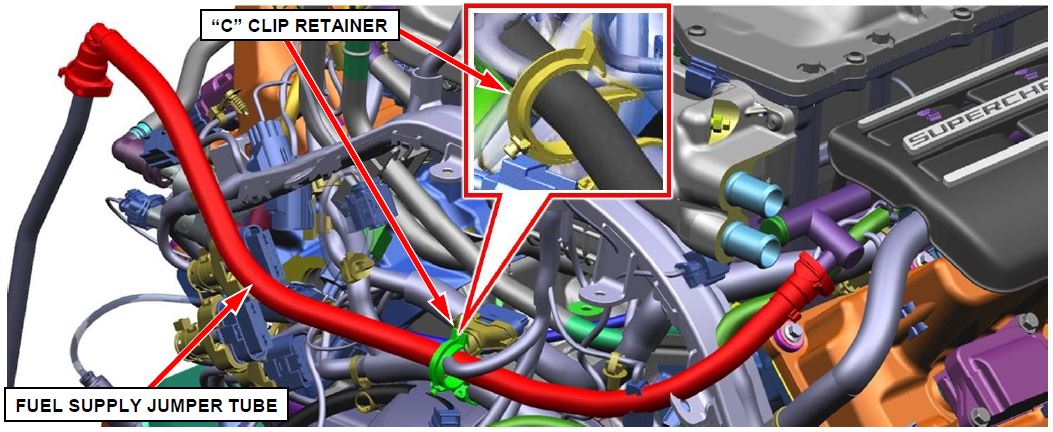

- Release the fuel supply jumper tube from the “C” clip retainer at the back of the engine (Figure 12).

Figure 11 – Fuel Supply Jumper QuickConnect Fitting Right Side of Engine

Figure 12 – Fuel Supply Jumper Tube “C” Clip Retainer

- Remove the fuel supply jumper tube from the engine then retain for part return. The fuel supply jumper tube is subject to parts return.

- Position the new fuel supply jumper tube to the engine.

- Install the fuel supply jumper tube into the “C” clip retainer at the back of the engine (Figure 12).

- Ensure that the fuel supply line and fuel rail connections are clean and free of debris before connecting the fuel supply jumper tube.

- Connect the fuel supply jumper tube to the fuel rail, then depress the redundant latch to secure the quick-connect fitting to the fuel rail (Figure 11).

- Connect the fuel supply jumper tube to the fuel supply line, then depress the redundant latch to secure the quick-connect fitting to the fuel supply line (Figure 8).

- Connect the negative battery cable terminal to the battery then tighten the clamp pinch-bolt hex nut to 5.5 N·m (50 In. Lbs.). For vehicles equipped with a supplemental battery, also connect the negative battery cable terminal to the supplemental battery (Figure 6).

NOTE: If equipped with an Intelligent Battery Sensor (IBS), connect the IBS electrical connector after connecting the negative battery cable terminal to the battery.

- Do not depress the brake pedal. Without starting the engine, place the ignition push button in the “RUN” position which will activate the fuel pump to pressurize the fuel system. Return the ignition push button to the “OFF” position.

NOTE: Repeat Step 24 three times to ensure that the fuel system is fully pressurized.

- Inspect the fuel supply jumper tube connections for any leaks. Correct any fuel leaks before continuing with the next step of this procedure.

- Position the engine covers with grommets over the ball studs (Figure 13). The right-side engine cover will need to be slid rearward toward the cowl to clear the coolant pipes.

Figure 13 – Engine Cover Studs

- Using hands only, gently push down on the engine covers until the grommets engage with the ball studs (Figure 7). Ensure grommet and ball stud retention by lightly lifting up around the edges of the engine cover to make certain that the cover is not loose and that all of the grommets are securely engaged.

- Close the engine compartment hood.

- Remove the fueling funnel from the fuel filler neck then close the fuel door (Figure 5).

- Return the fueling funnel to the storage area near the spare tire. Lower the load floor panel into position, then close the liftgate (Figure 4).

- Install the battery compartment cover.

- Return the front passenger seat to its original customer preferred position.

NOTE: One or more Diagnostic Trouble Codes (DTC)s may have been stored in the PCM memory due to fuel pump relay removal. The wiTECH diagnostic scan tool must be used to erase all DTCs.

- Connect the wiTECH micro pod II to the vehicle data link connector.

- Place the ignition in the “RUN” position.

- Open the wiTECH 2.0 website.

- Enter your “User id” your “Password” and your “Dealer Code”, then select “Finish” at the bottom of the screen.

- Starting at the “Vehicle Selection” screen, select the vehicle.

- From the “Topology” screen, select the “All DTCs” tab, then view and clear all DTCs.

- Place the ignition to the “OFF” position and remove the wiTECH micro pod II from the vehicle.

- Return the vehicle to the customer.

- Complete the proof of correction form for California residents.

Complete Proof of Correction Form for California Residents

This recall is subject to the State of California Registration Renewal/Emissions Recall Enforcement Program. Complete a Vehicle Emission Recall Proof of Correction Form (Form No. 81-016-1053) and supply it to vehicle owners residing in the state of California for proof that this recall has been performed when they renew the vehicle registration.

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments.

Use one of the following labor operation numbers and time allowances:

| Labor Operation Number | Time Allowance | |

|---|---|---|

| Inspect fuel supply jumper tube for separation | 14-U0-21-81 | 0.2 hours |

| Inspect and replace fuel supply jumper tube | 14-U0-21-82 | 0.5 hours |

Add the cost of the recall part plus applicable dealer allowance to your claim.

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

This notice applies to your vehicle,

[Model Year and Model] VIN XXXXXXXXXXXXXXXXX

U02/NHTSA 18V-048

LOGO

VEHICLE PICTURE

YOUR SCHEDULING OPTIONS

- RECOMMENDED OPTION Call your authorized Chrysler

/ Dodge

/ Dodge / Jeep

/ Jeep ® / RAM

® / RAM Dealership

Dealership - Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can confirm part availability and help schedule an appointment

- Visit recalls.mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App.

Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above.

DEALERSHIP INSTRUCTIONS Please reference Safety Recall U02.

IMPORTANT SAFETY RECALL

Fuel Supply Jumper Tube

Dear [Name],

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

FCA has decided that a defect, which relates to motor vehicle safety, exists in certain [2018 Model Year Jeep® Grand Cherokee Trackhawk] vehicles equipped with a 6.2L V8 supercharged engine.

It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers.

WHY DOES MY VEHICLE NEED REPAIRS?

The fuel line on your vehicle [1] could separate resulting in an engine stall and/or a potential engine compartment fire. Either of these conditions could increase the likelihood of occupant injury, and an engine stall can cause a vehicle crash without prior warning.

HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE?

FCA will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will inspect the fuel supplyjumper tube and replace it as needed. In addition, your dealer will require your vehicle for proper check-in, preparation, and check-out during your visit. Your time is important to us; please be aware that these steps may require more time. The estimated repair time is one hour. We recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership.

TO SCHEDULE YOUR FREE REPAIR CALL 1-800-853-1403

OR YOUR CHRYSLER , DODGE

, DODGE , JEEP

, JEEP OR RAM

OR RAM DEALER TODAY

DEALER TODAY

CALIFORNIA RESIDENTS

The State of California requires the completion of emission recall repairs prior to vehicle registration renewal. Your dealer will provide you with a Vehicle Emission Recall Proof of Correction Form after the Emission Recall service is performed. Be sure to save this form since the California Department of Motor Vehicles may require that you supply it as proof that the Emission Recall has been performed.

WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED?

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed.

We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Assistance/Field Operations

Fiat Chrysler

Chrysler Automobiles US LLC

Automobiles US LLC

Mr. Mrs. Customer

1234 Main Street

Hometown, MI 48371

[1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information.

[2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-4249153), or go to safercar.gov.

[3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement.

Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

1 Affected Product

Vehicle

JEEP | GRAND CHEROKEE | 2018 |

8 Associated Documents

Remedy Instructions and TSB – February 2018

RCRIT-18V048-7075.pdf 1669.828KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-18V048-6728.pdf 39.987KB

Loading...

Loading...

Recall 573 Report-Amendment 1

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 01/18/2018 New Safety Recall Advanced Communication – U02

Loading...

Loading...

Defect Notice 573 Report

Loading...

Loading...

Recall Acknowledgement

RCAK-18V048-1313.pdf 247.458KB

Loading...

Loading...

Recall Quarterly Report #3, 2018-3

RCLQRT-18V048-4640.PDF 211.325KB

Loading...

Loading...

Recall Quarterly Report #4, 2018-4

RCLQRT-18V048-2252.PDF 211.44KB

Loading...

Loading...

Latest Recalls Documents

- The world’s #1 fuel additive for both gasoline and diesel engines

- A great tune-up in a bottle – treats gasoline, diesel fuel and increases MPG

- Cleans and lubricates the fuel system, including fuel injectors, carburetor and combustion chamber

- Improves fuel economy by burning excess exhaust emissions

- Increases power and acceleration by improving fuel flow and reducing deposit buildup

- Clean fuel injectors and keeps them clean

- Reduces intake valve deposits and combustion chamber deposits

- Lubricates critical components in the fuel system and engine

- Stops knocking and hesitation

- Lessens oil contamination in older engines

- Restores fuel economy

- Stabilizes ethanol

- Maximizes horsepower

- Improves responsiveness

- For use in both gasoline and diesel engines

- Keeps fuel fresh for up to 24 months during storage

- Eliminates need to drain fuel prior to storage

- Ensures quick, easy starts after storage

- Effective in all gasoline, including ethanol blends

- For all gasoline engines, including 2-cycle

- ALL-ROUND ENGINE SOLUTION - Works in all engines and all fuels, making it the ideal fuel treatment and stabilizer for any vehicle or gas powered tool

- ETHANOL PROBLEM SOLVER - Prevents and cures most ethanol-related issues, including poor performance and decreased fuel economy

- OLD FUEL REVITALIZER - Stabilizes fuel up to 2 years and can help rejuvenate old, sub-spec fuel, even after months of inactivity

- FUEL ECONOMY MAXIMIZER - Removes and prevents gum, carbon deposits, and varnish build-up, resulting in improved fuel economy

- WATER BUILD-UP PREVENTION - Disperses water throughout fuel as submicron-sized droplets that are safely eliminated while the engine operates

- Includes AR6500 Diesel Treatment (40 oz)

- Includes AR6400-D Diesel Fuel System Cleaner

- Restore key fuel system components - injectors, turbo & dpf

- Boost cetane, improve performance and MPG

- AR6400-D is not the remedy for HEUI injector stiction. Please use AR9100 Friction Modifier instead

- Contains 100% High-Energy Solvent Technology

- Helps Keep Injectors Or Carb(S) And Intake Ports And Valves Clean

- Quickly Disperses Moisture And Dissolves Gum, Varnish, And Other Fuel Residues

- Disperses Moisture In Conventional Gasoline

- Save gas by keeping fuel intake system clean

- Helps restore performance

- Removes deposits from entire fuel system

- Helps inhibit corrosion

- Compatible with cap-less fuel tanks

- QUALITY ASSURED

- Reduces: rough idle, engine surge, hesitation, and spark plus fouling

- 20 oz. bottle.

- Improves: cold start performance, and fuel stability for up to one year

- Revitalize Your Engine: Gumout Multi-System Tune-Up is your ultimate fuel treatment gasoline solution, effortlessly cleaning GDI injectors, carburetors, and more for peak performance and fuel economy.

- Ultimate Engine Protection: Our advanced carburetor cleaner fuel additive prevents future carbon buildup, ensuring your engine runs smoothly. Perfect for gas, diesel, or ethanol engines, from cars to lawn mowers.

- Comprehensive Care: As a powerful fuel tank cleaner, Gumout cleans and conditions fuel systems, fighting ethanol and water corrosion while stabilizing fuel to reduce emissions and maximize engine life.

- Versatile Application: Add this gas treatment for car engines directly to the gas tank, crankcase, or via induction. Whether you're cleaning a carburetor or stabilizing gas, Gumout Multi-System Tune-Up has you covered.

Last update on 2025-04-17 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.