| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 18V523

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components SERVICE BRAKES, HYDRAULIC

Potential Number of Units Affected 154,335

Insufficient Coating on Rear Brake Caliper Pistons

A reduction of braking performance can increase the risk of a crash.

Summary

Chrysler (FCA US LLC) is recalling certain 2018-2019 Dodge

(FCA US LLC) is recalling certain 2018-2019 Dodge Grand Caravan and Jeep

Grand Caravan and Jeep Compass, 2018 Dodge

Compass, 2018 Dodge Journey, and 2019 Jeep

Journey, and 2019 Jeep Cherokee vehicles. The rear brake caliper pistons on these vehicles may have an insufficient coating causing gas pockets to form, potentially reducing rear brake performance.

Cherokee vehicles. The rear brake caliper pistons on these vehicles may have an insufficient coating causing gas pockets to form, potentially reducing rear brake performance.

Remedy

Chrysler will notify owners, and dealers will bleed the vehicle’s brake system, free of charge. The recall began September 29, 2018. Owners may contact Chrysler

will notify owners, and dealers will bleed the vehicle’s brake system, free of charge. The recall began September 29, 2018. Owners may contact Chrysler customer service at 1-800-853-1403. Chrysler

customer service at 1-800-853-1403. Chrysler ’s number for this recall is U86.

’s number for this recall is U86.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

Revision II August 2018

Dealer Service Instructions for:

Safety Recall U86 / NHTSA 18V-523 Low Brake Pedal

NOTE: Parts and claim submission information have been revised.

Remedy Available

NOTE: This recall applies only to the above vehicles built from March 17, 2018 through June 21, 2018 (MDH 031706 through 062101).

| IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement toapply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. |

Subject

The rear brake calipers on about 154,300 may have out-of-specification chrome coating on the pistons, which may cause gas pockets to form in the brake system. In some instances, the brake pedal may exhibit increased travel and/or feel soft after vehicle start. Gas pockets in the brake system may result in a reduction in rear brake performance, which can cause a vehicle crash without prior warning.

Repair

Bleed the entire brake system to remove any gas pockets.

Parts Information

| Qty. | Description | Part Number |

|---|---|---|

| up to 3 | Brake Fluid, DOT 3 | 04318080AD |

(or up to 36 fluid ounces of equivalent DOT3 fluid that complies with FMVSS116 or SAE J1703 – bill as “NPN”)

Dealers may already have the required brake fluid in their inventory. Additional allocations of brake fluid will be provided to dealers to service vehicles involved in this recall.

Parts Return

No parts return required for this campaign.

Special Tools

The following equipment is required to perform this repair:

| Clear Plastic Hose and Clear Jar |

Service Procedure

WARNING: When bleeding the brake system wear safety glasses. A clear bleed tube must be attached to the bleeder screws and submerged in a clear container filled part way with clean brake fluid. Direct the flow of brake fluid away from yourself and the painted surfaces of the vehicle. Brake fluid at high pressure may come out of the bleeder screws when opened.

CAUTION: Never use reclaimed brake fluid or fluid from a container which has been left open. An open container will absorb moisture from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based fluid in the brake hydraulic system. Use of such type fluids will result in seal damage of the vehicle brake hydraulic system causing a failure of the vehicle brake system. Petroleum based fluids would be items such as engine oil, transmission fluid, power steering fluid, etc.

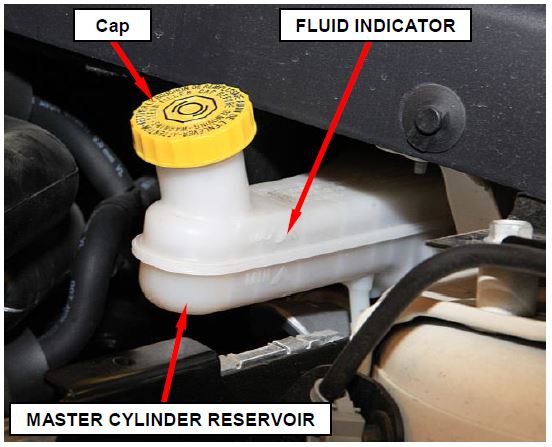

CAUTION: Before removing the master cylinder reservoir cap, thoroughly clean the cap and master cylinder fluid reservoir to prevent dirt and other foreign matter from dropping into the master cylinder fluid reservoir.

NOTE: The following wheel sequence should be used when bleeding the brake hydraulic system. The use of this wheel sequence will ensure adequate removal of all trapped air from the brake hydraulic system.

NOTE: The bleeding procedure described in this recall may be used to remove air from the brake system. Pressure bleeding is recommended if pressure bleeding equipment is available. If pressure bleeding equipment is available, follow the manufacturer’s directions for proper use.

Service Procedure

NOTE: The aid of a helper will be required during this entire brake bleed process.

- Open the hood.

- Clean the master cylinder reservoir and cap before opening the reservoir (Figure 1).

- Add fluid if necessary to raise the fluid level to the MAX indicator on the side of the reservoir (Figure 1).

Figure 1 – Master Cylinder Reservoir

- Ensure the helper is either in the vehicle or is able to access the vehicle while raised on the lift before beginning the bleeding procedure

- Raise and support the vehicle.

- Attach a clear plastic hose to the bleeder screw and feed the hose into a clear jar containing enough fresh brake fluid to submerge the end of the hose (Figure 2).

Figure 2 – Brake Bleeding Equipment

- Have the helper pump the brake pedal three or four times and hold it in the down position.

- With the pedal in the down position, open the brake caliper bleeder screw at least one full turn.

- Once the brake pedal has dropped, close the brake caliper bleeder screw. After the bleeder screw is closed, release the brake pedal.

- Repeat the above steps until all trapped air is removed from that wheel circuit (usually four or five times).

- Monitor the fluid level in the master cylinder reservoir to make sure it does not go dry.

- Bleed the remaining wheel circuits in the same manner as described in Steps 6 – 10 until all air is removed from the brake system.

- Check and adjust brake fluid level to the FULL mark.

- Ensure that the vehicle battery is fully charged before bleeding the Antilock Brake System (ABS).

- Connect the wiTECH micro pod II to the vehicle data link connector.

- Place the ignition in the “RUN” position.

- Open the wiTECH 2.0 website.

- Enter your “User id” and “Password” and your “Dealer Code”, then select “Sign In” at the bottom of the screen. Click “Accept”.

- From the “Vehicle Selection” screen, select the appropriate vehicle.

- View and clear all Diagnostic Trouble Codes (DTCs) before beginning.

- From the “Action Items” screen, select the “Topology” tab

- From the “Topology” tab, select the “ABS” module icon.

- Select the “Misc Functions” tab.

- Within the “Misc Functions” tab, select “Bleed Brake Procedure” or “ABS Bleed Brakes” then follow the wiTECH on screen instructions.

- After performing the ABS bleeding procedure, place the ignition in the “OFF” position and then remove the wiTECH micro pod II device from the vehicle.

NOTE: After performing the ABS bleeding procedure, the brake calipers must be blead a second time to remove any air released by the ABS.

- Bleed all four brake calipers in the same manner as described in Steps 6 – 12 until all air is removed from the brake system.

- Remove any bleeder equipment from the vehicle.

- Lower the vehicle.

- Check and adjust brake fluid level to the FULL mark on the reservoir.

- Close hood.

- Check brake pedal travel and feel.

- If pedal travel is normal proceed to Step 32.

- If pedal travel is excessive or if the pedal feels excessively spongy, some air may still be trapped in the system. Re-bleed the brakes as necessary.

- Test drive the vehicle to verify the brakes are operating properly and pedal feel is correct. If not correct, additional bleeding may be required.

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments.

Use the following labor operation number and time allowances:

| Labor Operation Number | Time Allowance | |

|---|---|---|

| Bleed Brake System (JC and RT vehicles) | 05-U8-61-82 | 1.1 hours |

| Bleed Brake System (MP vehicles) | 05-U8-61-82 | 1.0 hours |

| Bleed Brake System (KL vehicles) | 05-U8-61-82 | 1.2 hours |

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

If utilizing a non-Mopar DOT3-equivalent brake fluid, submit the U86 Recall claim with an NPN Part line item at dealer cost. Appropriate mark-up will be applied systematically.

PLEASE NOTE:

- Upon entering the NPN Part (000000NPN) on the claim, a brief description of the NPN part is required to be entered in the NPN Part Description Entry field.

- Dealer must retain the following support: Itemized part receipt showing dealer cost, core charges and discounts, etc.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

This notice applies to your vehicle,

[Model Year and Model] VIN XXXXXXXXXXXXXXXXX U86/NHTSA 18V-523

LOGO

VEHICLE PICTURE

YOUR SCHEDULING OPTIONS

- RECOMMENDED OPTION Call your authorized Chrysler

/ Dodge

/ Dodge / Jeep

/ Jeep / RAM

/ RAM Dealership

Dealership - Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can confirm part availability and help schedule an appointment

- Visit mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App.

QR Code

Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above.

DEALERSHIP INSTRUCTIONS

Please reference Safety Recall U86.

IMPORTANT SAFETY RECALL

Low Brake Pedal

Dear [Name],

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

FCA has decided that a defect, which relates to motor vehicle safety, exists in certain [2018 model year (JC) Dodge Journey, 2018 and 2019 model year (RT) Dodge Caravan, 2018 and 2019 model year (MP) Jeep Compass, and 2019 model year (KL) Jeep Cherokee] vehicles.

It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers.

WHY DOES MY VEHICLE NEED REPAIRS?

The rear brake calipers on your vehicle [1] may have out-of-specification chrome coating on the pistons, which may cause gas pockets to form in the brake system. In some instances, the brake pedal may exhibit increased travel and/or feel soft after vehicle start. Gas pockets in the brake system may result in a reduction in rear brake performance, which can cause a vehicle crash without prior warning.

HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE?

FCA will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will bleed the entire brake system to remove any gas pockets. In addition, your dealer will require your vehicle for proper check-in, preparation, and check-out during your visit. Your time is important to us; please be aware that these steps may require more time. The estimated repair time is two hours. We recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership.

TO SCHEDULE YOUR FREE REPAIR,

CALL YOUR CHRYSLER, DODGE, JEEP OR RAM DEALER TODAY

WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED?

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed.

We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Assistance/Field Operations

Fiat Chrysler

Chrysler Automobiles US LLC

Automobiles US LLC

Mr. Mrs. Customer

1234 Main Street

Hometown, MI 48371

[1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information.

[2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-4249153), or go to safercar.gov.

[3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement.

Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

U86

Revision II August 2018

Loading...

Loading...

U86

Revised August 2018

Loading...

Loading...

U86

August 2018

Loading...

Loading...

Safety Recall Advanced Communication – U86

08/16/2018

Loading...

Loading...

MOPAR > Communications

U86 Safety Recall (Low Brake Pedal) Parts Allocation and Dealer Ordering Update

September 13, 2018

Loading...

Loading...

MOPAR > Communications

U86 Safety Recall (Low Brake Pedal) Parts Availability, Customer Notification & Service Capacity

September 04, 2018

Loading...

Loading...

MOPAR > Communications

U86 Safety Recall (Low Brake Pedal) Parts Availability & Supply Update

August 23, 2018

Loading...

Loading...

MOPAR > Communications

U86 Safety Recall (Lower Brake Recall)

August 20, 2018

Loading...

Loading...

Recall Acknowledgement

August 22, 2018

Loading...

Loading...

Latest Recalls Documents

- Provides an extra margin of safety in extreme braking conditions

- Mix of polyglycol ethers ensures hot brake-system operation will not create dangerous vapor

- Excellent for ABS, disc and drum brake systems

- Delivers braking power when needed by avoiding a spongy pedal

- Both wet and dry boiling points exceed the minimum government standards

- High compatibility. Use with or direct replacement for DOT 3, DOT 4, and DOT 5. 1

- Extended Service Interval (ESI): Lasts 100 percent longer than DOT 3, 50 percent longer than DOT 4, and 10 percent longer than DOT 5. 1

- Exceeds all DOT 3, DOT 4, and DOT 5. 1 standards

- Wet boiling point ~ 365 DegreeF/Viscosity at -40 DegreeC ~ 685mm2/s

- Standard brake fluid has a recommended change interval of 2 years. The recommended change interval for Bosch ESI6 is 3 years.

- Premium DOT 3 Brake Fluid has a minimum boiling point of 450°F

- Meets and exceeds DOT 3 and all other Federal and SAE specifications and standards for motor vehicle brake fluids

- Mixes with all DOT 3 approved brake fluids

- Designed for use in disc, drum and ABS brake systems

- Premium brake and hydraulic clutch fluid that protects internal components from corrosion under normal use

- High boiling point to minimize brake fluid boiling and vapor lock

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Synthetic quality brake fluid

- Contains special ingredients to guard against vapor lock and moisture absorption

- Exceeds requirements for both DOT 3 and DOT 4 brake fluids

- Specially formulated for DOT 4 brake fluid applications

- Designed for use in disc, drum and ABS brake systems

- The 336⁰F wet boil point and 521⁰F dry boil point exceeds common characteristics for DOT 4 brake fluids

- Provides corrosion protection in brake components

- Matches needs of all DOT 4 manufacturer recommendations

- Compatible with all DOT 3 and DOT 4 applications

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.