| “This site contains affiliate links for which OEMDTC may be compensated” |

March 3, 2020 NHTSA CAMPAIGN NUMBER: 20V124000

Clutch Pressure Plate May Overheat

The overheated clutch components may increase the risk of a fire. Additionally, damage to other nearby components can result in debris falling onto the road or a loss of drive, increasing the risk of a crash.

NHTSA Campaign Number: 20V124

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components POWER TRAIN

Potential Number of Units Affected 33,237

Summary

Chrysler (FCA US LLC) is recalling certain 2018-2020 Jeep

(FCA US LLC) is recalling certain 2018-2020 Jeep Wrangler and 2020 Gladiator vehicles equipped with manual transmissions. The clutch pressure plate may overheat and fracture.

Wrangler and 2020 Gladiator vehicles equipped with manual transmissions. The clutch pressure plate may overheat and fracture.

Remedy

Chrysler will notify owners, and dealers will reroute a wire harness and inspect the clutch system, and replace components as needed. The recall began April 30, 2020. Owners may contact Chrysler

will notify owners, and dealers will reroute a wire harness and inspect the clutch system, and replace components as needed. The recall began April 30, 2020. Owners may contact Chrysler customer service at 1-800-853-1403. Chrysler

customer service at 1-800-853-1403. Chrysler ’s number for this recall is W12.

’s number for this recall is W12.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

Revision 3 July 2020

Dealer Service Instructions for:

Safety Recall W12 / NHTSA 20V-124 Clutch

NOTE: Removed the STAR ordering restriction from the Parts Information section, the Service Procedure section, and the Completion Reporting and Reimbursement section.

Remedy Available

NOTE: This recall applies only to the above vehicles equipped with a 6-speed manual transmission (sales code DEM).

NOTE: Some vehicles above may have been identified as not involved in this recall and therefore have been excluded from this recall.

| IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement toapply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. |

Subject

In some circumstances, the clutch pressure plate on about 36,750 of the above vehicles may become overheated through friction, which may lead the pressure plate to fracture. A fractured pressure plate may crack or fracture the transmission case, allowing heated debris to contact ignition sources on the vehicle, potentially leading to a vehicle fire. In some circumstances, the operator may smell a burnt clutch odor, or have excessive or abnormal clutch pedal travel prior to the failure. A vehicle fire can result in occupant injury and injury to persons outside the vehicle, as well as property damage. A fractured pressure plate may also lead to a loss of propulsion, or generation of road debris. Either of these two conditions can cause a vehicle crash without prior warning.

Repair

Remove the hydraulic hose reservoir hose clip and discard, install a hose sleeve, and bleed the clutch slave cylinder on all of the above vehicles, start the service procedure at section A. Clutch Master Cylinder Inspection.

Alternate Transportation

Dealers should attempt to minimize customer inconvenience by placing the owner in a loaner vehicle if inspection determines that repair is required and the vehicle must be held overnight.

Parts Information

| Description | Part Number |

| Fluid, Brake DOT 3 (MS-4574) | 04318080AD |

|

|

NOTE: The following PN: CSDLW123AA is to be installed on all involved vehicles.

| Description | Part Number |

| Part Package | CSDLW123AA |

| Each package contains the following components: | |

| Description | Quantity |

| Sleeve, Hose | 1 |

NOTE: The following part packages below are to be ordered if the Clutch Health test failed and air bubbles have been observed while performing the Clutch Slave Cylinder Inspection procedure in section A and B.

| Description | Part Number |

| Part Package* | CSDLW121AA |

| Each package contains the following components: | |

| Description | Quantity |

| Bolt, Clutch to Flywheel | 6 |

| Bolt, Flywheel to Crankshaft | 8 |

| Bearing | 1 |

| Pivot | 1 |

| Bolt, Propshaft to T-case | 12 |

| Bolt, “Y” Pipe | 4 |

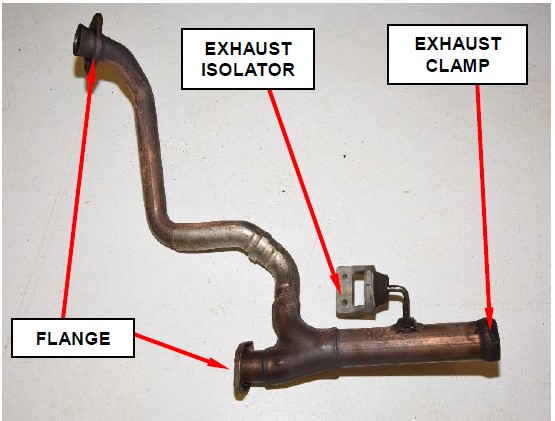

| Clamp, Exhaust | 1 |

| Bolt, Center Bearing to Bracket | 2 |

| Tie Strap | 1 |

| Tie Strap | 1 |

| Tie Strap | 1 |

| Bolt, Front Propshaft to Axle | 4 |

| Description | Part Number |

| Part Package* | CSDLW124AA |

| Each package contains the following components: | |

| Description | Quantity |

| Kit, Clutch | 1 |

| Description | Part Number |

| Part Package* | CSDLW125AA |

| Each package contains the following components: | |

| Description | Quantity |

| Flywheel Assembly | 1 |

NOTE: The following PN: CSDLW122AA is to be ordered if any leak/seepage, deformation, or wear is found while performing section A. Clutch Master Cylinder Inspection.

| Description | Part Number |

| Part Package* | CSDLW122AA |

| Each package contains the following components: | |

| Description | Quantity |

| Hose, Hydraulic Upper | 1 |

Parts Return

The Pressure Plate, Disc and Flywheel will be subject to parts return.

Please make sure to retain the Pressure Plate, Disc and Flywheel until the recall claim is paid, go to the “Parts” tab and click on the “Return material Utility” in “DealerCONNECT”. In the” Dispositions” tab it will give a disposition of “Return”. In the “Tickets” tab under “UPS ground”, the claim will be listed. Select the ticket and follow the process to generate a “Part Return Document”, “UPS Shipping Label” and “UPS Receipt”. Place the Pressure Plate, Disc, Flywheel and the Part Return Document inside the box, the new part came in. Attach the UPS Shipping label on the outside of the box and ship to:

Quality Engineering Center 2021

Executive Hills Blvd.

Auburn Hills, MI 48326

Special Tools

The following special tools are required to perform this repair:

| Tool, Flywheel Locking 10272 |

| Kit, Vacuum Hand Pump |

Service Procedure

A. Clutch Master Cylinder Inspection.

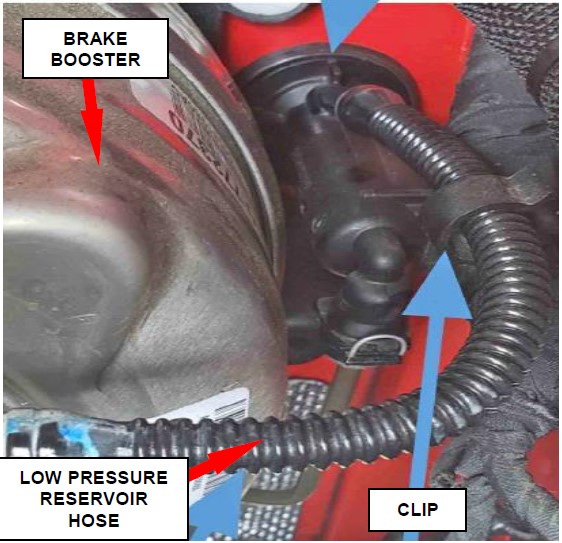

- Locate and cut the clip holding the wire harness to the low pressure reservoir hose and Discard the clip (Figure 1).

Figure 1 – Low Pressure Reservoir Hose

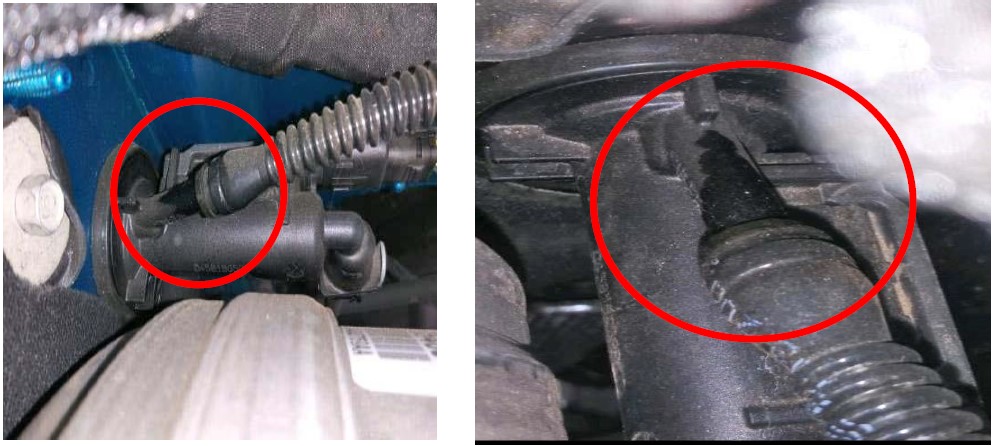

- Visually inspect the low pressure reservoir hose for any leaks/seepage (See Sample Pictures Below), if leak or seepage, deformation, or wear is found replace the reservoir hose (Figure 1).

NOTE: Place shop towels to protect paint surface and components from fluid spill, wipe away fluid from components and surface immediately.

SAMPLE of Leak/Seepage

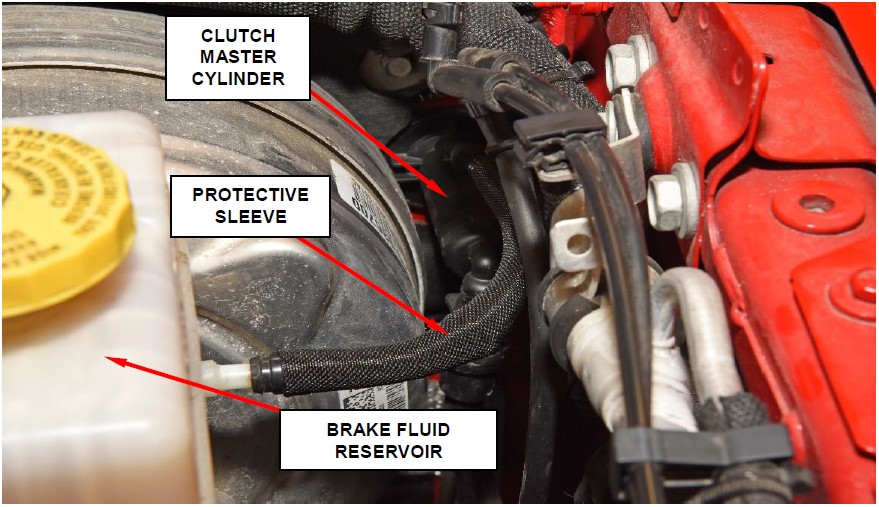

- Install the protective sleeve on the low pressure reservoir hose, making sure it is installed close to the clutch master cylinder inlet tube (Figure 2).

NOTE: If the reservoir hose is replaced, actuate the clutch pedal 50 times, making sure the pedal is getting to the top of its return stroke each time (this may require that you lift the pedal to the top of the stroke).

Figure 2 – Hose Sleeve Installed

NOTE: During bleed process below, note if any air bubbles are observed in the clear hose.

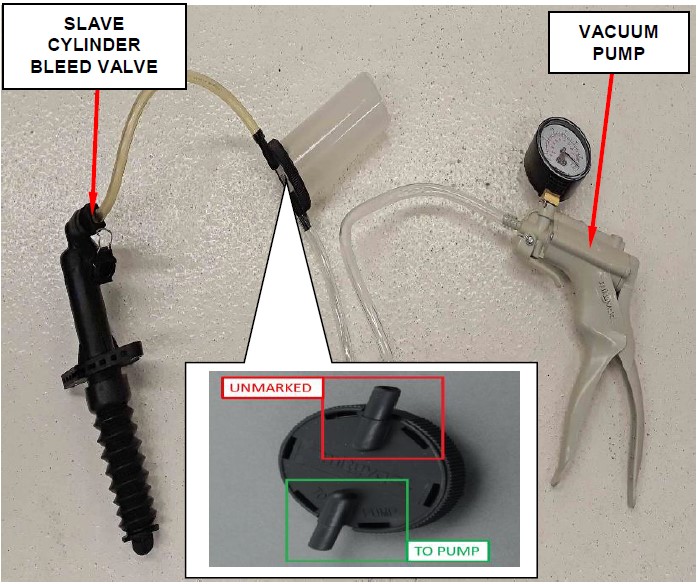

- Perform the hydraulic clutch system bleed, using the Mityvac tool and follow the provided steps below.

- Assemble the Mightyvac tool using adequate length of clear hose as shown in figure 3.

Figure 3 – Mityvac Tool Assembled

a) Install bungee cord or equivalent to hold the clutch pedal up.

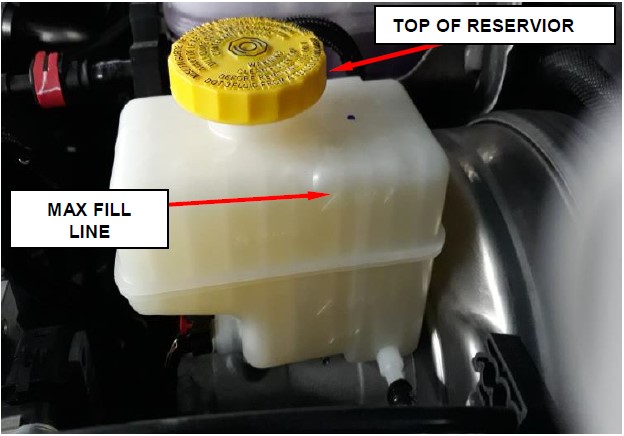

b) Remove the reservoir cap and fill the brake/clutch fluid reservoir to top of reservoir (Figure 4).

c) Raise and support the vehicle on a hoist.

d) Remove the rubber cap covering the Clutch Release Cylinder (CRC) bleed valve.

e) Install a length of clear tubing onto the CRC bleed valve.

f) Connect the other end of the clear tubing to the UNMARKED port on the Mityvac clear bottle (Figure 3).

Figure 4 – Brake/Clutch Fluid Reservoir

g) Connect the Mityvac pump side hose to the port marked TO PUMP on the Mityvac clear bottle (Figure 3).

h) Using the Mityvac system, create and maintain a minimum vacuum of 20 mmHg on the CRC bleed valve.

i) Fully open the CRC bleed valve.

j) While maintaining vacuum on the CRC bleed valve, continue the process until 60mL of brake fluid is removed.

k) Fully close the CRC bleed valve.

l) Lower the vehicle and top off the brake/clutch fluid reservoir to the top of the reservoir (above MAX fill) (Figure 4).

m) Repeat steps h – l at least five more times or until there are no more air bubbles observed through the clear hose.

n) Remove the Mityvac system and reinstall the rubber cap on the CRC bleed valve.

o) Lower the vehicle on the hoist.

p) Install brake fluid reservoir cap (Note: Align cap tabs to reservoir tabs).

q) Remove bungee cord from clutch pedal.

r) Actuate the pedal 50 times, making sure the pedal is getting to the top of its return stroke each time (this may require that you lift the pedal to the top of the stroke).

s) At the brake/clutch fluid reservoir, top off or remove fluid as necessary to reach the MAX fill line on the reservoir.

t) Engage the parking brake, verify the vehicle is in Neutral, start engine and verify clutch operation and pedal feel.

u) If the clutch pedal is not returning to the top of its stroke, or does not disengage the clutch, repeat the bleeding procedure.

- During bleed process were any air bubbles observed traveling through the clear hose?

- YES: Proceed to section Clutch Health Check Procedure

- NO: No further service required, return the vehicle to the customer.

B. Clutch Health Check Procedure

NOTE: The clutch health check procedure requires a technician that has experience in driving manual transmission vehicles.

NOTE: Limit the test to one time, to prevent excessive clutch odor.

- Move vehicle to a parking lot, away from pedestrians or other vehicles.

- Close all windows and turn HVAC system off prior to starting procedure below.

- Fully engage the parking brake.

- Fully depress to the clutch pedal and move shift lever into 4th gear.

- Raise the engine to 4,000 RPM (Revolutions Per Minute).

- Engage the clutch rapidly and simultaneously move the accelerator to wide open throttle.

NOTE: Do not slide foot off the clutch pedal, simply rapidly release your foot.

- If the engine stalls immediately without the engine RPM increasing, the clutch heath test has passed, no further service is required return the vehicle to the customer.

NOTE: Allow a minimum of 5 minutes for the clutch odor to dissipate before returning vehicle to the customer.

- If the engine RPM increases (indicating clutch slippage) and then stalls the clutch health test failed, follow section C. Replace Clutch Procedure.

- If the engine RPM increases (indicating clutch slippage) but does not stall the clutch health test failed, follow section Replace Clutch Procedure.

C. Replace Clutch Procedure.

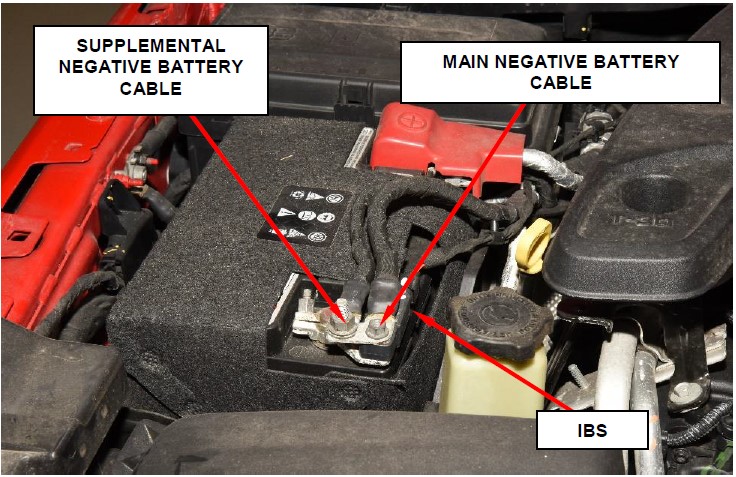

a) Remove the nut for the supplemental battery negative cable and isolate the cable. (Figure 5).

b) Remove the nut for the main negative cable and isolate the cable (Figure 5).

c) Disconnect the IBS (Figure 5).

Figure 5 – Battery Negative Cable(s)

NOTE: If the battery negative cables are not isolated it will result in the system still having battery connection and a potential power spike or power of the system and can cause damage or deployment of air bags.

- Raise and support the vehicle.

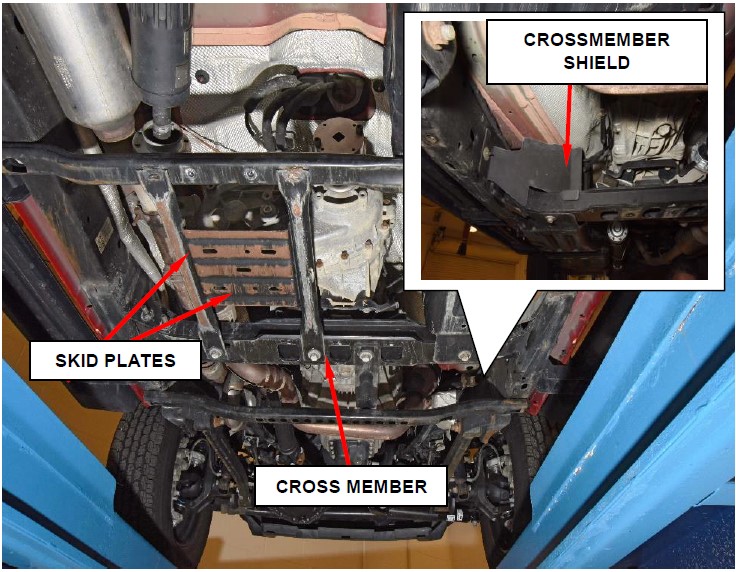

- Remove the crossmember shield (Figure 6).

- If equipped: remove the skid plates (Figure 6).

- Support the transmission with a suitable transmission jack.

- Remove the cross member bolts.

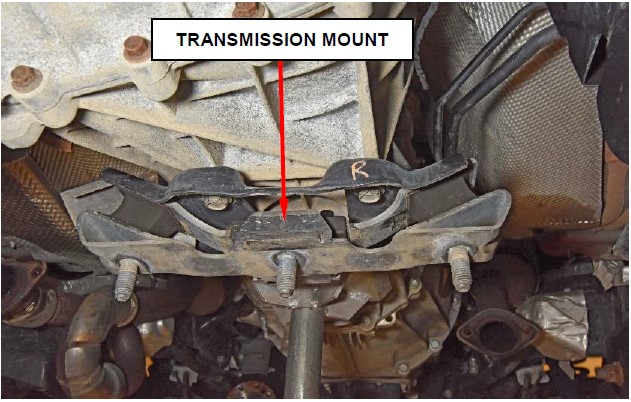

- Remove the transmission cross member (Figure 6).

Figure 6 – Skid Plates

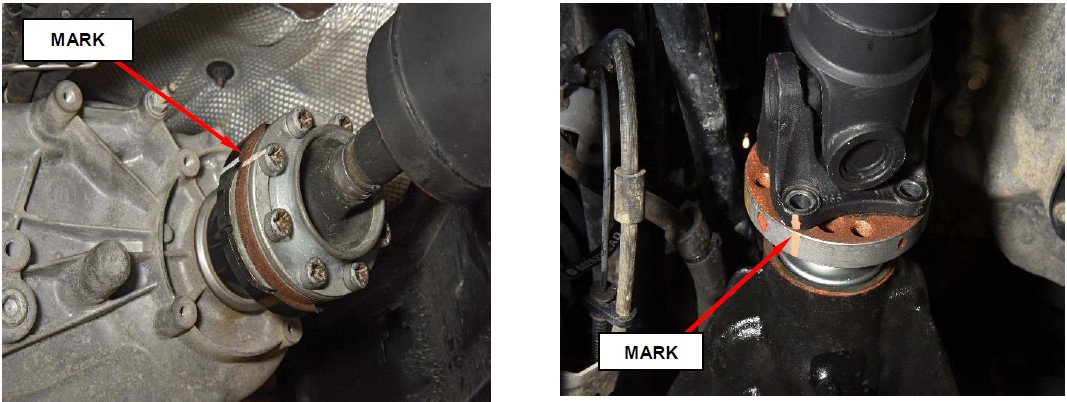

- Mark the transfer case rear flange and the propeller shaft for installation reference before removing the propeller shaft. Mark the transfer case front flange and the front propeller shaft before removing the propeller shaft (Figure 7 and Figure 8).

Figure 7 – Transfer Case Flange Figure 8 – Front Propeller Shaft

- Remove the rear drive shaft flange bolts at the transfer case and the bolts at the rear axle and remove propeller shaft and set aside (Figure 7).

NOTE: Apply rust penetrant to the exhaust bolt threads and allow to saturate to ease bolt removal.

- Remove the exhaust clamp.

- Remove the right side exhaust flange bolts.

- Remove the left side exhaust flange bolts.

- Remove the exhaust isolator fasteners.

- Remove the “Y” pipe (Figure 9).

Figure 9 – “Y” Pipe

- Remove the transmission mount (Figure 10).

Figure 10 – Transmission Mount

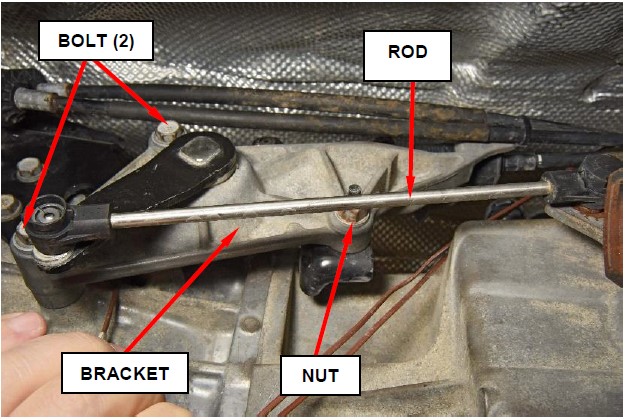

- Disconnect the rod from the bracket ball stud, then remove the two bolts and nut attaching the transfer case rod to the bracket and position aside (Figure 11).

Figure 11 – Rod Bracket

- Remove the nut attaching the wire bracket to the transfer case.

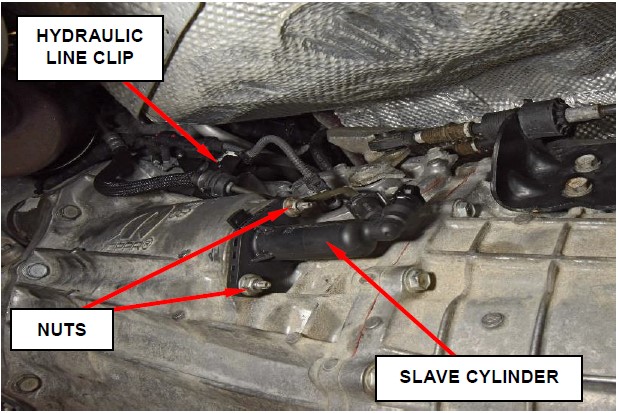

- Remove the clutch slave cylinder hydraulic line clip bolt and the 2 nuts, then remove the clutch slave cylinder and position aside (Figure 12).

Figure 12 – Slave Cylinder

- Disconnect the neutral switch electrical connector.

- Using a suitable tool, disconnect the shift cables from the transmission bracket.

CAUTION: Do not remove the shift cable bracket.

CAUTION: If any of the shift cables or shift cable brackets are removed, the cable adjustment must be checked. This adjustment is critical. If not set correctly, transmission damage is possible .

- Position the shift cables away from the transmission.

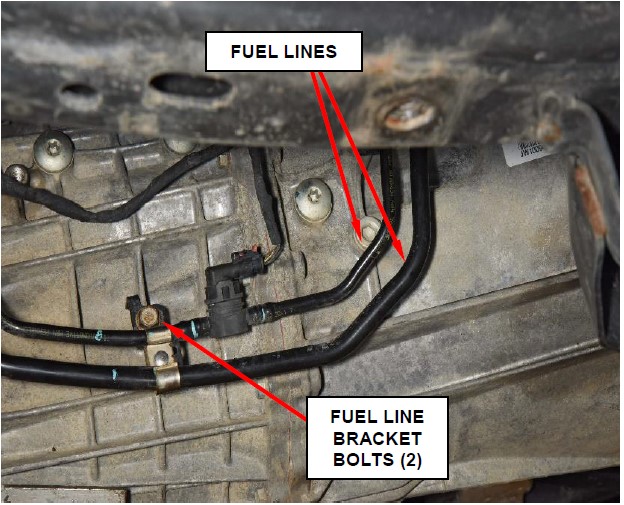

- Remove the bolts attaching the fuel line bracket to the transmission (Figure 13).

Figure 13 – Fuel Lines

- Disconnect the wiring harness fir tree retainers from the transmission.

- Unlock the electrical connector from the transfer case range position switch and disconnect the wire harness connector.

- Unlock the electrical connector from the all gear sensor on the transmission and disconnect the wire harness connector.

- Slightly lower the transmission.

- Using a suitable jack, support the transfer case. Using safety chains, secure transfer case to the jack.

- Remove the seven bolts securing the transfer case to the transmission assembly.

- Move the transfer case assembly rearward until it is free of the transmission output shaft.

- Lower the jack and remove the transfer case from under the vehicle

- Disconnect the transmission vent hose from the transmission.

- Remove the transmission to engine mounting bolts.

- Move the transmission rearward until the input shaft is clear of the clutch assembly.

- Lower the transmission jack and the transmission and set aside.

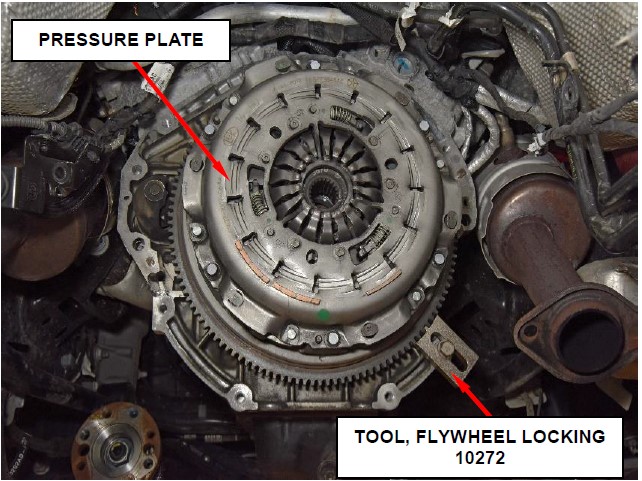

- Install the Tool, Flywheel Locking 10272 onto back of the engine block (Figure 14),

NOTE: It may be necessary to install an appropriate length 10 MM bolt, washer and nut in place of the supplied 12 MM fastener.

Figure 14 – Locking Tool Installed

- Loosen clutch assembly bolts evenly, a few threads at a time and in a diagonal pattern to prevent warping the clutch assembly (Figure 14).

WARNING: FCA US LLC does not manufacture any vehicles or replacement parts that contain asbestos. Aftermarket products may or may not contain asbestos. Refer to aftermarket product packaging for product information. Whether the product contains asbestos or not, dust and dirt can accumulate on manual clutch parts during normal use. Follow practices prescribed by appropriate regulations for the handling, processing and disposing of dust and debris.

- While holding the clutch and disc against the flywheel, remove the bolts holding the pressure plate to the flywheel and DISCARD the bolts, save the Clutch and Pressure Plate for parts return.

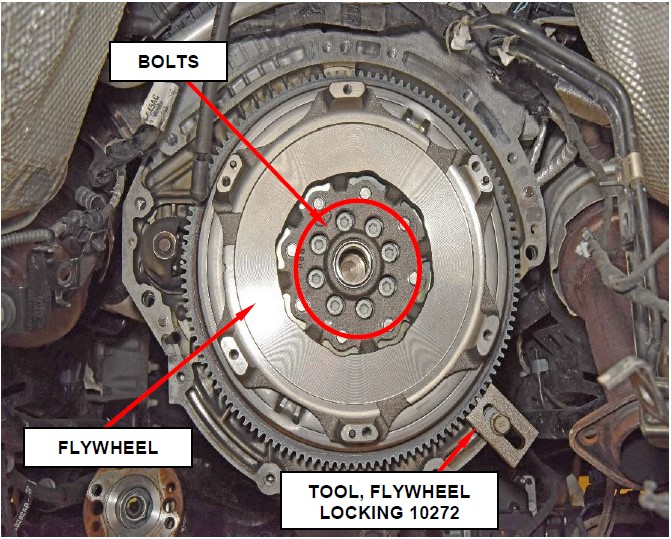

- Remove the flywheel bolts and the flywheel. DISCARD the bolts and save Flywheel for parts return.

- Install the NEW flywheel and NEW bolts tighten flywheel bolts evenly and in rotation a few threads at a time. The bolts must be tightened evenly to 52N·m (38ft. lbs.) (Figure 15).

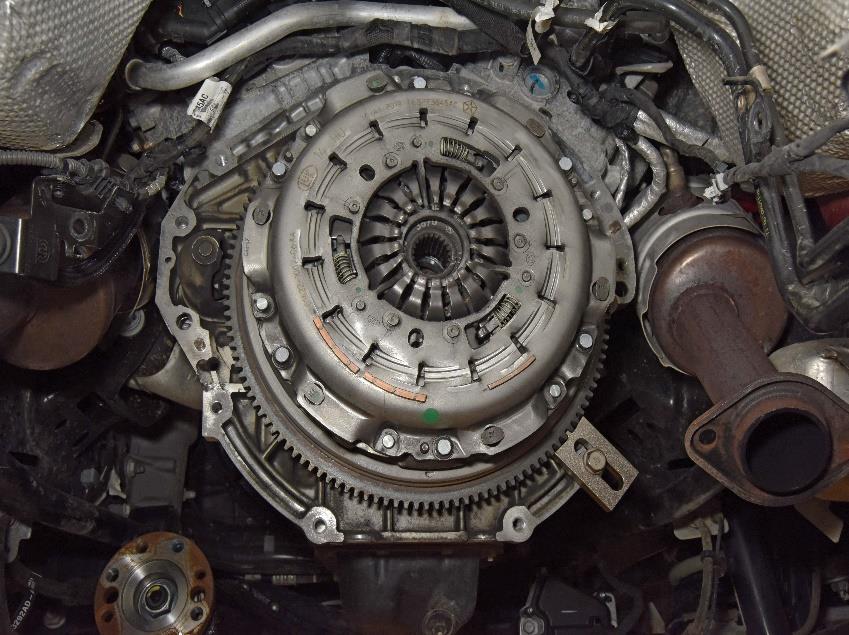

- Install the NEW clutch pressure plate to the flywheel and NEW clutch disc. Finger tighten the clutch assembly to flywheel bolts (Figure 14).

Figure 15 – Flywheel

NOTE: Clutch disk does not require a clutch alignment tool for installation.

- Tighten clutch assembly bolts evenly and in rotation a few threads at a time. The bolts must be tightened evenly and to specified torque to avoid distorting the clutch assembly.

- Using a “star” torque pattern, tighten the pressure plate bolts to 30N·m (22ft.lbs.).

Figure 16 – Clutch Pressure Plate Installed

- Remove the Clutch Fork and wipe clean.

- Remove the throw-out bearing and DISCARD.

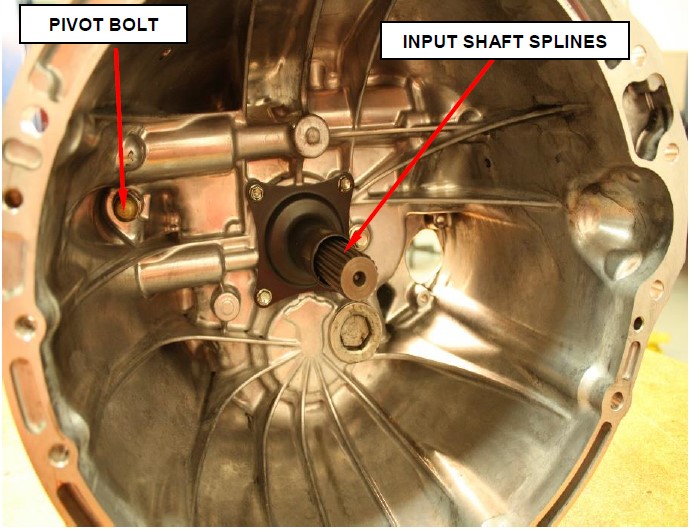

- Remove the pivot bolt and DISCARD.

- Install the NEW Pivot bolt and tighten to 25N·m (18ft. lbs.) (Figure 17).

NOTE: Wipe the Transmission input Shaft Splines and Clutch Fork clean before installing NEW bearing and applying NEW grease.

- Apply a very light coat of Mopar® high temperature bearing grease or equivalent to the input shaft splines (0.3 grams) (Figure 17).

Figure 17 – Pivot Bolt

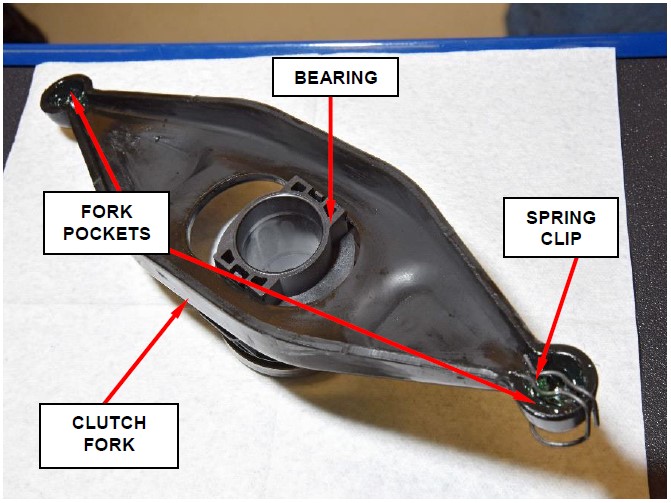

- Replace the clutch release bearing and apply a thin coat of Mopar® high temperature bearing grease to clutch fork / release bearing interface (Figure 18).

Figure 18 – Clutch Fork Assembly

- Position clutch release bearing to clutch release fork and properly snap in place, ensure clips are fully seated. Apply 1 gram of Mopar® high temperature bearing grease to fork pockets. Position spring clip to fork and snap in place as shown in figure 18. Position sub assembled fork/bearing/spring clip to trans guide shaft/quill, then slide in place. Position spring clip over trans pivot ball stud then snap in place. Ensure properly seated.

- Continue to section D. Transmission Installation.

D. Transmission Installation

- Clean the transmission front housing mounting surface.

- Position the transmission under the vehicle and raise the position into place.

- Carefully push transmission forward to align the transmission input shaft and dowel pins into the transmission.

- Install the transmission mounting bolts and tighten to 50N·m (37ft. lbs.).

- Install the fuel line fasteners and brackets to the transmission.

- Install the starter motor assembly and tighten the bolts to 47N·m (35ft. lbs.).

- Reconnect the vent hose to the transmission.

- Align and seat the transfer case on the transmission. Be sure the transfer case input gear splines are aligned with the transmission output shaft. Align the splines by rotating the transfer case rear output shaft yoke if necessary. Do not install any transfer case attaching bolts until the transfer case is completely seated against the transmission and tighten the bolts to 60N·m (45ft lbs.).

- Fasten the wire form to the transfer case and tighten the nut to 20N·m (15ft. lbs.)

- Route and attach the wiring harnesses to the clips located on the case.

- Reconnect the electrical connector to the transmission all gear sensor.

- Reconnect the electrical connector to the transfer case range position sensor.

- Attach the shifter cables to the shift cable bracket and transmission ball studs.

CAUTION: If any of the shift cables or shift cable brackets are removed, the cable adjustment must be checked. This adjustment is critical. If not set correctly, transmission damage is possible

- Install the transfer case rod bracket and tighten the 2 bolts and nut to 24N·m (18ft. lbs.) (Figure 11).

- Attach the transfer case rod to the ball lever, use channel lock style pliers to press the rod back on the lever (Figure 11).

- Install the wire form on the transfer case tighten the nut to 20N·m (15ft. lbs.)

- Insert the slave cylinder into the transmission , and install the nuts and bolt, and tighten to 17 N·m (13ft. lbs.) (Figure 12).

NOTE: Slave cylinder must be inserted in-line with the mounting studs, failure to install the slave cylinder correctly may result in damaging the slave cylinder.

CAUTION: Bore scope inspection required to ensure clutch fork to slave cylinder alignment. Failure to inspect and verify proper seating of the slave may result in transmission damage or loss of clutch function.

NOTE: Ensure slave cylinder is properly seated within fork pocket.

- Install the front driveshaft to axle flange with the reference marks aligned and tighten the NEW front driveshaft to front axle flange bolts to 121N·m (89ft. lbs.) Tighten the NEW front driveshaft to transfer case flange bolts to 39N·m (29ft. lbs.) (Figure 8).

- Install the rear driveshaft with the reference marks aligned and tighten the NEW bolts to 39N·m (29ft. lbs.) (Figure 7).

- JT Model: Align and Install NEW center bearing mount bolts and tighten to 62 N·m (46ft. lbs.).

- Install the “Y” exhaust pipe and install NEW bolts tighten to 18N·m (13ft. lbs.) and install a NEW exhaust clamp and tighten to 26Nm (19ft. lbs.).

- Install the transmission mount and tighten the bolts to 54N·m (40ft. lbs.) (Figure 10).

- Install the transmission cross-member (Figure 6).

- Install the left side transmission cross-member to frame bolts and tighten to120N·m (129ft. lbs.).

- Install the left side transmission to cross-member nuts hand tight.

- Install the right side transmission cross-member to frame bolts and tighten to to72N·m (53ft. lbs.).

- Tighten the left side transmission cross- member to frame nuts to120N·m (129ft lbs.).

- Lower the transmission until the weight is on the rear isolator, then remove the support.

- Install the rear isolator to transmission cross-member nuts and tighten to 175N·m (129ft. lbs.).

- Install the exhaust hanger bolts and tighten to 25N·m (18ft. lbs.).

- Install the fuel tank shield to transmission cross-member bolt and tighten securely.

- Install the transfer case skid plate tighten the bolts to 75N·m (55ft. lbs.).

- Lower the vehicle.

- Connect the negative battery cable(s) and tighten to 6N·m (53in. lbs.).

- Road Test vehicle to verify proper vehicle performance and verify transfer case shifts and functions in all ranges (2HI, 4HI, NEUTRAL, and 4LO) shift functionality, before returning the vehicle to the customer.

- Return the vehicle to the customer.

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments.

| Labor Operation Number | Time Allowance | |

| Remove tie strap, install hose sleeve, inspect reservoir hose for leak, bleed hydraulic clutch | 06-W1-21-82 | 0.5 hours |

| Remove tie strap, install hose sleeve, replace reservoir hose, bleed hydraulic clutch, perform clutch health test | 06-W1-21-83 | 0.6 hours |

| Remove tie strap, install hose sleeve, replace reservoir hose, bleed hydraulic clutch, perform clutch health test, replace Clutch, Flywheel, Pressure Plate, slave cylinder, pivot bearing | 06-W1-21-84 | 4.6 hours |

| Optional Equipment | ||

| Two Piece Propeller Shaft | 06-W1-21-61 | 0.2 hours |

| Floor Plan Reimbursement | 95-95-95-97 | Calculate See Below |

Use the following labor operation numbers and time allowances:

Floor Plan Reimbursement

Floor Plan Reimbursement represents the vehicle’s average daily allowance (see table below) multiplied by the number of days the vehicle was in dealer inventory and not available for sale. This reimbursement is limited to the number of days from the date of the stop sale to the date that the remedy was made available.

Note: If the vehicle was received by your dealership (KZX date) AFTER the stop sale date, you will use the KZX date instead of the stop sale date. For this Recall, the stop sale was initiated on 03/10/2020 and the remedy was made available on 04/30/2020, therefore, the number of days cannot exceed 51 days.

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. To use this system, click on the “Service” tab and then click on “Global Recall Completed vehicles are removed from GRS within several days of repair claim submission.

System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

This notice applies to your vehicle,

[Model Year and Model] VIN XXXXXXXXXXXXXXXXX

W12/NHTSA 20V-124

LOGO

VEHICLE PICTURE

YOUR SCHEDULING OPTIONS

- RECOMMENDED OPTION Call your authorized Chrysler

/ Dodge

/ Dodge / Jeep® / RAM

/ Jeep® / RAM Dealership

Dealership - Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can confirm part availability and help schedule an appointment

- Visit recalls.mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App.

Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above.

DEALERSHIP INSTRUCTIONS

Please reference Safety Recall W12.

IMPORTANT SAFETY RECALL

Dear [Name],

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

FCA US has decided that a defect, which relates to motor vehicle safety, exists in certain [2018 -2020 Model Year (JL) Jeep Wrangler and 2020 (JT) Jeep Gladiator] vehicles.

It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers.

WHY DOES MY VEHICLE NEED REPAIRS?

In some circumstances, the clutch pressure plate on your vehicle [1] may become overheated through friction, which may lead the pressure plate to fracture. A fractured pressure plate may crack or fracture the transmission case, allowing heated debris to contact ignition sources on the vehicle, potentially leading to a vehicle fire. In some circumstances, the operator may smell a burnt clutch odor, or have excessive or abnormal clutch pedal travel prior to the failure. A vehicle fire can result in occupant injury and injury to persons outside the vehicle, as well as property damage. A fractured pressure plate may also lead to a loss of propulsion, or generation of road debris. Either of these conditions can cause a vehicle crash without prior warning.

HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE?

FCA US will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will install a protective hose sleeve, reroute a wire harness, inspect the clutch system, and replace components as needed. The estimated repair time is about one hour. However, if inspection determines additional components need to be replaced additional time may be necessary. In addition, your dealer will require your vehicle for proper check-in, preparation, and check-out during your visit, which may require more time. Your time is important to us, so we recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership.

TO SCHEDULE YOUR FREE REPAIR,

CALL YOUR CHRYSLER, DODGE, JEEP OR RAM DEALER TODAY

WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED?

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed.

We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Assistance/Field Operations

FCA US LLC

Mr. Mrs. Customer

1234 Main Street

Hometown, MI 48371

[1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information.

[2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-4249153), or go to safercar.gov.

[3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement.

Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

03/04/2020

New Safety Recall Advanced Communication – W12

FCA US LLC (FCA US) has announced a safety recall on certain 2018 – 2020 Model Year (JL) Jeep® Wrangler and 2020 (JT) Jeep® Gladiator vehicles equipped with a manual transmission.

REASON FOR THIS SAFETY RECALL

In some circumstances, the clutch pressure plate on the above vehicles may become overheated through friction, which may lead the pressure plate to fracture. A fractured pressure plate may crack or fracture the transmission case, allowing heated debris to contact ignition sources on the vehicle, potentially leading to a vehicle fire. A vehicle fire can result in occupant injury and injury to persons outside the vehicle, as well as property damage. A fractured pressure plate may also lead to a loss of propulsion, or generation of road debris. Loss of propulsion, can cause a vehicle crash without prior warning.

WARNING WHICH CAN PRECEDE OR OCCUR

In some circumstances, the operator may smell a burnt clutch odor, or have excessive or abnormal clutch pedal travel prior to the failure.

SERVICE ACTION

The remedy for this condition is currently under development. Dealers will be notified of the launch of this safety recall by way of established communication methods.

We ask that you please take the time to ensure that your personnel are aware of this communication and are prepared to execute a customer friendly process for inquiries regarding involved vehicles.

Customer Services Field Operations

FCA US LLC

03/10/2020

New Safety Recall Advanced Communication – W12

FCA US LLC (FCA US) has announced a safety recall on certain 2018 – 2020 Model Year (JL) Jeep® Wrangler and 2020 (JT) Jeep® Gladiator vehicles equipped with a manual transmission.

VINs identified as being involved in this campaign are currently live and searchable. Stop sale is in effect for the above-identified vehicles.

Vehicles impacted by a stop sale are eligible for reimbursement allowance through the Recall Floorplan Reimbursement Policy (RFPRP), which can be requested upon recall claim submission.

IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Violation of this requirement by a dealer could result in a civil penalty of up to $21,000 per vehicle. Involved vehicles can be determined by using the VIP inquiry process.

REASON FOR THIS SAFETY RECALL

In some circumstances, the clutch pressure plate on the above vehicles may become overheated through friction, which may lead the pressure plate to fracture. A fractured pressure plate may crack or fracture the transmission case, allowing heated debris to contact ignition sources on the vehicle, potentially leading to a vehicle fire. A vehicle fire can result in occupant injury and injury to persons outside the vehicle, as well as property damage. A fractured pressure plate may also lead to a loss of propulsion, or generation of road debris. Loss of propulsion, can cause a vehicle crash without prior warning.

WARNING WHICH CAN PRECEDE OR OCCUR

In some circumstances, the operator may smell a burnt clutch odor, or have excessive or abnormal clutch pedal travel prior to the failure.

SERVICE ACTION

The remedy for this condition is currently under development. Dealers will be notified of the launch of this safety recall by way of established communication methods.

We ask that you please take the time to ensure that your personnel are aware of this communication and are prepared to execute a customer friendly process for inquiries regarding involved vehicles.

Customer Services Field Operations

FCA US LLC

4 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| JEEP | GLADIATOR | 2020 |

| JEEP | WRANGLER | 2018-2020 |

16 Associated Documents

ISSUED Owner Notification Letter(Part 577)

RCONL-20V124-1852.pdf 58.345KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-20V124-6126.pdf 2084.282KB

Loading...

Loading...

Recall 573 Report

RCLRPT-20V124-7170.PDF 215.446KB

Loading...

Loading...

Recall 573 Report

RCLRPT-20V124-8403.PDF 215.446KB

Loading...

Loading...

Recall 573 Report – Amendment 1

RCLRPT-20V124-6513.PDF 215.873KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-20V124-3745.pdf 2085.585KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Dealer Notification re New Safety Recall Advanced Communication – W12

RCMN-20V124-7584.pdf 102.964KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-20V124-8022.PDF 215.456KB

Loading...

Loading...

Recall Acknowledgement

RCAK-20V124-4724.pdf 244.336KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-20V124-2807.pdf 2243.131KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-20V124-1465.pdf 2011.318KB

Loading...

Loading...

Recall Quarterly Report #1, 2020-2

RCLQRT-20V124-2848.PDF 211.144KB

Loading...

Loading...

Recall Quarterly Report #3, 2020-4

RCLQRT-20V124-4152.PDF 211.337KB

Loading...

Loading...

Recall Quarterly Report #2, 2020-3

RCLQRT-20V124-8364.PDF 211.247KB

Loading...

Loading...

ISSUED Renotification Notice

RCRN-20V124-0603.pdf 137.966KB

Loading...

Loading...

Latest Recalls Documents

- All technical questions answered by highly trained customer support staff.

- All Kits are assembled in the U.S. using only top quality components.

- Our products are designed according to OE specifications.

- We offer the industry's most reliable 12-month/12,000-mile warranty.

- HIGH-QUALITY CLUTCH REPLACEMENT: Our clutch kit is precision-engineered for your vehicle, delivering a perfect fit and reliable performance. Rigorously tested to meet applicable OEM performance specifications, it ensures smooth and efficient operation.

- COMPATIBLE WITH MULTIPLE MODELS: The LuK RepSet 05-065 Clutch Kit is designed for Dodge

and Jeep engines from 92-06 and is compatible with the Dodge

and Jeep engines from 92-06 and is compatible with the Dodge B250 92-93, Dakota 92-99, Jeep Cherokee 94-01, Grand Cherokee 94-96, and Wrangler 94-95/97-06 models.

B250 92-93, Dakota 92-99, Jeep Cherokee 94-01, Grand Cherokee 94-96, and Wrangler 94-95/97-06 models. - COMPLETE CLUTCH KIT: Designed to enable a hassle-free installation, the replacement transmission clutch kit comes with a new clutch, new disc, spline lubricant, all necessary release bearings, pilot bearings, and spline tools.

- LONG-LASTING PERFORMANCE: Our OEM Repsets are built to handle the demands of everyday driving as well as more extreme driving situations, making them ideal for both maintenance and repair needs.

- EXPERTISE OF OVER 30 YEARS: As an Original Equipment Supplier, Schaeffler has been the preferred choice of professionals over the years and offers high-quality automotive solutions for cars, trucks, SUVs, vans, motorcycles, scooters, ATVs, and UTVs.

- [Vehicle Fitment]: Compatible with Dodge

B150 1992-1993 V6 3.9L, Dakota 1992-1999 V6 3.9L; Compatible with Jeep XJ Series Cherokee 1994-2001 L6 4.0L, ZJ Series Grand Cherokee 1994-1996 L6 4.0L, YJ Series Wrangler 1994-1995 L6 4.0L, TJ Series Wrangler 1997-2006 L6 4.0L

B150 1992-1993 V6 3.9L, Dakota 1992-1999 V6 3.9L; Compatible with Jeep XJ Series Cherokee 1994-2001 L6 4.0L, ZJ Series Grand Cherokee 1994-1996 L6 4.0L, YJ Series Wrangler 1994-1995 L6 4.0L, TJ Series Wrangler 1997-2006 L6 4.0L - [Reference Number]: 05-065, L05065, 05065 --- You can select the "Year/Make/Model" or other parameters of your car at the top of the list and click "Confirm" before purchasing. Check if this "Clutch Kit" is suitable for your car

- [Specifications]: ①Clutch Diameter: 12-3/8 inch; ②Clutch Disc Diameter: 10-2/5 inch; ③Clutch Disc Spline Quantity: 10; ④Input Shaft Diameter: 1-3/20 (1.15) inch; ⑤Number of clutch disc springs: 5

- [Kit Contents]: Designed to enable a hassle-free installation, the replacement transmission clutch kit comes with Pressure Plate, Clutch Disc, Release Bearing, Pilot Bearing, Alignment Tool, Disc Lubricant Grease

- [Buy with Confidence]: This Clutch kit is made with optimal design and sturdily in mind. Each component, from the Pressure Plate to the Clutch Disc, is engineered to withstand high-performance demands while maintaining reliable operation ensures a long-lasting solution for better performance. In addition, A-Premium offers a one-year unlimited-mileage guarantee on our meticulously crafted clutch kit

- A Complete Clutch Kit: EFT Stage 2 Clutch Kit contains all the essential components: EFT Heavy-Duty Cast Flywheel (26 lbs), Pressure Plate, Stage 2 HD Carbon Sprung Disc (10-3/8" , 10 spline), Throwout Bearing, Pilot Bushing, Alignment Tool, Installation Guide. It offers everything you need for a seamless repair in one package

- Unmatched Compatibility: This Clutch Set is designed for Jeep Cherokee 1994 - 2000, Jeep Grand Cherokee (1994 - 2000) (4.0L OHV 6cyl) and (1994 - 2004) Jeep Wrangler (4.0L OHV 6cyl). This clutch kit ensures maximum compatibility and performance

- Direct Factory Replacement: The EFT Stage 2 Clutch Kit is a direct factory replacement, meaning it fits seamlessly into your vehicle without requiring any modifications. It’s designed to restore or upgrade your vehicle’s clutch system with no additional custom work, making installation easy and efficient

- Optimal Design and Durability : This Clutch Kit is crafted with optimal design and durability in mind. Its ideal-quality components, including carbonized friction material and a heavy-duty sprung center, ensure long-lasting performance under demanding conditions

- Warranty: Exedy Clutch Kit comes with 12-month Brand warranty, providing assurance of its quality and durability. It ensures reliable performance and peace of mind for up to a year from the date of purchase. The images provided for reference purposes only. Please refer to the product description for specific details

- PREMIUM CLUTCH YOU CAN FEEL AND TRUST: ClutchMaxPRO is defining a new meaning of affordable performance clutch. It is simply the best bang and quality for the buck. Period. All ClutchMaxPRO products are designed, engineered, assembled, tested and inspected right here in the U.S.A. to ensure highest quality and satisfaction.

- INDUSTRY LEADING CUSTOMER SUPPORT: We offer industry's best technical support to ensure 100% satisfaction

- KIT INCLUDES: Solid Nodular Flywheel (146 ring gear count), OEM HD Pressure Plate, OEM HD Clutch Disc (10-3/8" x 1-1/8" x 10 spline), OEM HD Throw-out Bearing, OEM HD Pilot Bearing, Alignment Tool and Installation Guide.

- LIMITED WARRANTY: All ClutchMaxPRO products comes with excellent customer support and limited manufacturer warranty of 12 months or 15,000 miles that covers issues related to performance, fitment and function. Buy with confidence!

- THE FOLLOWING PRODUCT IS COMPATIBLE WITH: 2007 - 2011 Jeep Wrangler (3.8L OHV 6cyl)

- PREMIUM CLUTCH YOU CAN FEEL AND TRUST: ClutchMaxPRO is defining a new meaning of affordable performance clutch. It is simply the best bang and quality for the buck. Period. All ClutchMaxPRO products are designed, engineered, assembled, tested and inspected right here in the U.S.A. to ensure highest quality and satisfaction.

- HORSEPOWER RATING AND TORQUE CAPACITY: 264 HP / 283 lb-ft, Suitable for daily use, performance street driving, moderate towing and moderate off-roading.

- KIT INCLUDES: Nodular HD Type Flywheel, Performance Pressure Plate, Performance Stage 2 Carbon Kevlar Infused Disc (10-3/8" x 1-1/8" x 10 spline), Throw-out Bearing, Pilot Bearing, Alignment Tool and Installation Guide

- LIMITED WARRANTY: All ClutchMaxPRO products comes with excellent customer support and limited manufacturer warranty of 12 months or 15,000 miles that covers issues related to performance, fitment and function. Buy with confidence!

- THE FOLLOWING PRODUCT IS COMPATIBLE WITH: 1994 - 2001 Jeep Cherokee (4.0L OHV 6cyl; XJ), 1994 - 2001 Jeep Grand Cherokee (4.0L OHV 6cyl; WJ, ZJ), 1997 - 2004 Jeep TJ (4.0L OHV 6cyl), 1994 - 2004 Jeep Wrangler (4.0L OHV 6cyl; CJ; DJ; TJ)

- All technical questions answered by highly trained customer support staff.

- All Kits are assembled in the U.S. using only top quality components

- Our products are designed according to OEM specifications

- We offer the industry's most trusted warranty of 12 months/12,000 miles

- Our products are designed according to OEM specifications

- All Kits are assembled in the U.S. using only top quality components

- Highly Trained Customer Support avaialble to answer all your technical questions

- Limited Warranty: XTD products comes with excellent customer support and limited manufacturer warranty of 6 months or 12,000 miles that covers issues related to performance, fitment and function.

- compatible with : 2012-2017 Jeep Wrangler All Trim

- Direct replacement - this clutch master cylinder is built to match the original clutch master in specific vehicles

- Precise design - reverse-engineered from original equipment to fit seamlessly and function reliably

- Durable materials - includes high-grade rubber components for compatibility with standard brake fluid

- Trustworthy value - backed by team of engineers and quality control experts in the United States

- Ensure fit - to make sure this part fits your exact vehicle, input your make, model and trim level into the garage tool

- PREMIUM CLUTCH YOU CAN FEEL AND TRUST: ClutchMaxPRO is defining a new meaning of affordable performance clutch. It is simply the best bang and quality for the buck. Period. All ClutchMaxPRO products are designed, engineered, assembled, tested and inspected right here in the U.S.A. to ensure highest quality and satisfaction.

- HORSEPOWER RATING AND TORQUE CAPACITY: 260 HP / 285 lb-ft, Suitable for daily driving, performance street driving, moderate towing and off-roading use.

- KIT INCLUDES: Nodular HD Flywheel, Performance Pressure Plate, Performance Stage 2 Carbon Kevlar Infused Disc (8-7/8" x 1" x 14 spline), Throw-out Bearing, Pilot Bearing, Alignment Tool and Installation Guide.

- LIMITED WARRANTY: All ClutchMaxPRO products comes with excellent customer support and limited manufacturer warranty of 12 months or 15,000 miles that covers issues related to performance, fitment and function. Buy with confidence!

- THE FOLLOWING PRODUCT IS COMPATIBLE WITH: 1994 - 2000 Cherokee (2.5L OHV 4cyl), 1997 - 2002 Wrangler TJ (2.5L OHV 4cyl), 1994 - 2002 Wrangler (2.5L OHV 4cyl)

Last update on 2025-04-17 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.