| “This site contains affiliate links for which OEMDTC may be compensated” |

March 14, 2019

Steering Wheel May Detach From Steering Column

If the steering wheel detaches from the steering column, the driver may lose control of the vehicle, increasing the risk of crash.

NHTSA Campaign Number: 19V201

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components STEERING

Potential Number of Units Affected 52

Summary

Chrysler (FCA US LLC) is recalling certain 2019 Jeep

(FCA US LLC) is recalling certain 2019 Jeep Wrangler and 2019 Ram

Wrangler and 2019 Ram 1500 vehicles. These vehicles have improperly machined steering column stub shafts that may break, possibly causing the steering wheel to detach from the steering column.

1500 vehicles. These vehicles have improperly machined steering column stub shafts that may break, possibly causing the steering wheel to detach from the steering column.

Remedy

Chrysler will notify owners, and dealers will inspect the steering column, replacing it, as necessary, free of charge. The recall began April 5, 2019. Owners may contact FCA US customer service at 1-800-853-1403. Chrysler

will notify owners, and dealers will inspect the steering column, replacing it, as necessary, free of charge. The recall began April 5, 2019. Owners may contact FCA US customer service at 1-800-853-1403. Chrysler ’s number for this recall is V29.

’s number for this recall is V29.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

March 2019

Dealer Service Instructions for:

Safety Recall V29 / NHTSA 19V-201

Steering Column

Remedy Available

NOTE: This recall applies only to the above vehicles.

NOTE: Some vehicles above may have been identified as not involved in this recall and therefore have been excluded from this recall.

IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process.

Subject

The steering column on about 50 of the above vehicles may have been built with an improperly machined steering column stub shaft that may break, and could allow the steering wheel to detach from the steering column. A steering wheel separation from the steering column may result in a loss of steering control, and can cause a vehicle crash without prior warning, as well as a compromised driver front impact safety system, increasing the risk of driver injury in a vehicle crash.

Repair

Inspect the steering column, and if necessary replace the steering column assembly in all affected vehicles.

Alternate Transportation

Dealers should attempt to minimize customer inconvenience by placing the owner in a loaner vehicle if inspection determines that a steering column is required and the vehicle must be held overnight.

Parts Information

NOTE: Parts can only be ordered through campaignteam@fcagroup.com. Please provide the VIN, Mileage, PN, and Dealer Code. The Supply Chain team will order the parts.

Parts Return

No parts return required for this campaign.

Special Tools

The following special tools are required to perform this repair:

| ➢ NPN | wiTECH micro pod II |

| ➢ NPN | Laptop Computer |

| ➢ NPN | wiTECH Software |

| ➢ 2050200100 | Remover, Driver Air Bag |

| Contact the Mopar Essential Tool Call Center (1-855-298-2687) to arrange for the Rental of Tool 2069700190 – Check Tool, Steering Stub Shaft. | |

| ➢ 2069700190 | Check Tool, Steering Stub Shaft |

Service Procedure

A. Inspect Steering Column

WARNING: To avoid serious or fatal injury on vehicles equipped with airbags, disable the Supplemental Restraint System (SRS) before attempting any steering wheel, steering column, airbag, seat belt tensioner, impact sensor or instrument panel component diagnosis or service. Disconnect and isolate the battery negative (ground) cable, then wait two minutes for the system capacitor to discharge before performing further diagnosis or service. This is the only sure way to disable the SRS. Failure to take the proper precautions could result in accidental airbag deployment.

WARNING: To avoid serious or fatal injury, the driver airbag trim cover must never be painted. Replacement airbags are serviced with trim covers in the original colors. Paint may change the way in which the material of the trim cover responds to an airbag deployment. Failure to observe this warning could result in occupant injuries upon airbag deployment.

- Disconnect and isolate the negative battery cable(s) then wait two minutes for the system capacitor to discharge.

- For DT trucks, Locate the access hole dimples (1) in the lower surface of the steering wheel hub rear trim cover near each of the two horizontal spokes (Figure 1).

Figure 1 – Access Hole Dimples (DAB)

- For DT trucks, using the Remover, Driver Air Bag 2050200100, pierce the trim cover at the dimple and insert it through one of the steering wheel access holes. A guide and notch integral to each side of the steering wheel hub rear trim cover and the mounting/horn switch plate will assist in directing the tool to the ends of the retainer spring.

- For DT trucks, when the tool makes contact with the retainer spring, push inward (toward the steering column) on the tool far enough to disengage the retainer spring from under the hook of the steering wheel armature.

- For DT trucks, pull the released side of the DAB away from the steering wheel far enough to insert a trim stick or another long and thin obstacle between the released spoke of the DAB trim cover and the steering wheel spoke hub cavity. This will help to prevent the released end of the retainer spring from becoming accidentally engaged again while the opposite end of the retainer spring is being released.

- For DT trucks, repeat Steps 3 and 4 for the opposite end of the retainer spring.

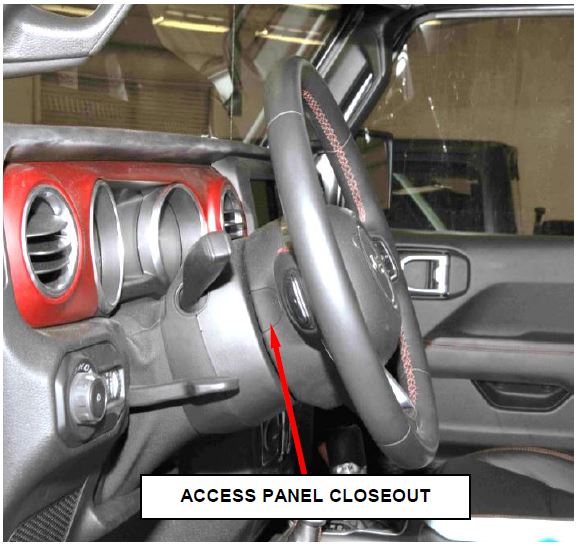

- For JL vehicles, remove the two access panel closeouts on the steering wheel near each of the two horizontal spokes (Figure 2).

- For JL vehicles, remove and save the two driver airbag retaining bolts from the driver airbag (Figure 2).

Figure 2 – Driver Airbag

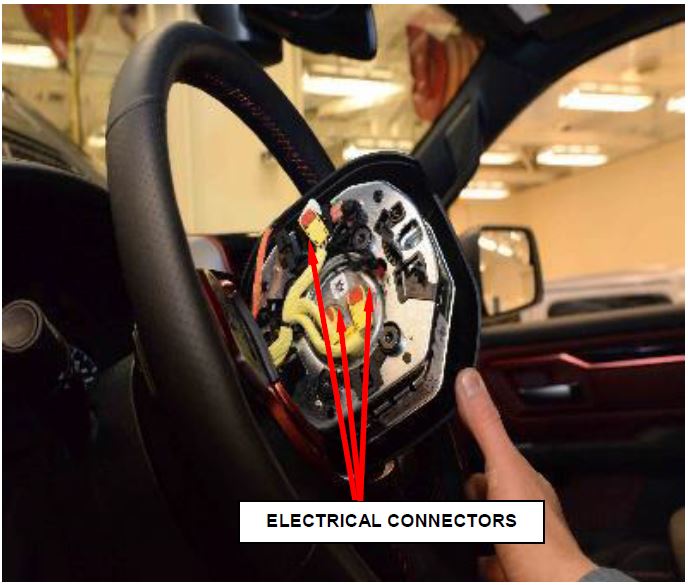

- Pull the DAB away from the steering wheel far enough to access the steering wheel wire harness connector to the DAB inflator initiators (Figure 3).

Figure 3 – Wire Harness Connectors (DT shown, JL Similar)

CAUTION: Do not pull on the clockspring pigtail wires or pry on the connector insulators to disengage them from the Driver AirBag (DAB) inflator initiator connector receptacles. Improper removal of these pigtail wires and their connector insulators can result in damage to the airbag circuits or the connector insulators.

- The clockspring DAB pigtail wire connector insulators are secured by integral latches and a Connector Position Assurance (CPA) lock to the airbag tether cutter and inflator connector receptacles, which are located on the back of the floating horn switch plate and the DAB housing. Pull the lock straight away from the connector insulator, then pull the insulators straight away from the connector receptacles to disengage and disconnect them.

- Remove the DAB and floating horn switch plate from the steering wheel as a unit (Figure 4).

Figure 4 – DAB (DT shown, JL Similar)

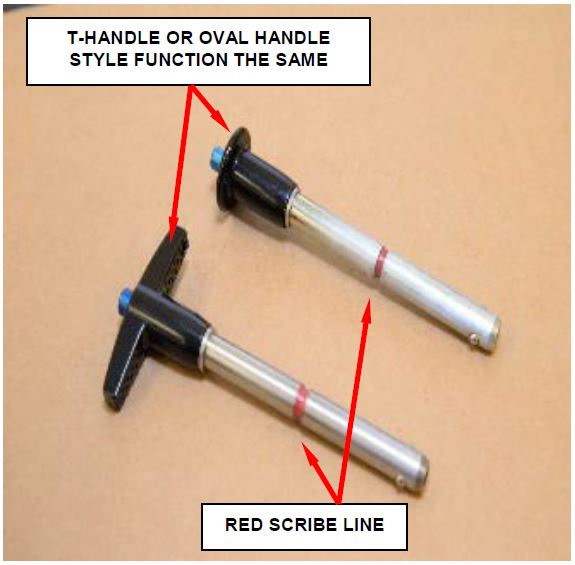

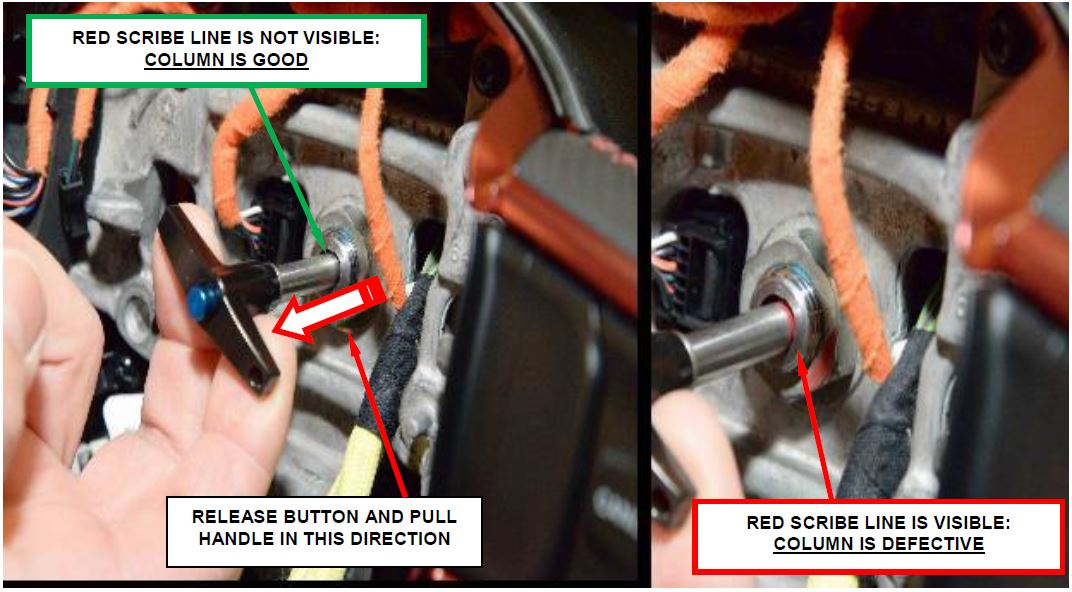

- Use the provided Check Tool, Steering Stub Shaft for the vehicle stub shaft inspection (Figure 5). See Special Tool section for rental instructions.

- Push the blue button on the end of the tool prior to insertion.

- Note the RED scribe line on the tool.

Figure 5 – Check Tool (Two Handle Styles)

- Insert the tool into the steering column stub shaft until tool bottoms out in steering column (Figure 6).

- Release blue button.

- Pull back on tool until the tool bottoms out inside of the shaft.

- If you do not see the RED scribe line on the tool outside of the column shaft, the column is GOOD. Continue to Step 16.

- If you do see the RED scribe line on the tool outside of the column shaft. The steering column is DEFECTIVE. Vehicle is required to have column replaced. Push blue button to remove tool from shaft. Continue to Section Replace DT Steering Column or Section C. Replace JL Steering Column.

- Push blue button to remove tool from shaft.

Figure 6 – Inspect Steering Column Stub Shaft

- For DT trucks, position the DAB close enough to the steering wheel to connect the steering wheel wire harness connectors to the DAB inflator initiators.

- For DT trucks, connect the clockspring pigtail wire connectors to the airbag inflator initiator connector receptacles by pressing straight in on the connector insulator. Be certain to engage each keyed and color-coded connector to the matching connector receptacle. Be certain that each connector is fully engaged in its receptacle, then push the connector lock straight into the connector to lock it in place.

- For DT trucks, carefully position the DAB to the steering wheel hub cavity while tugging lightly upward on the clockspring pigtail wires for the airbag and tucking the wires in the upper hub cavity of the steering wheel. Be certain that none of the steering wheel wiring is pinched between the airbag housing or the horn switch and the steering wheel armature.

- For DT trucks, using both hands, push firmly and evenly on both sides of the DAB trim cover until both ends of the spring retainer have snapped in place under the hooks within the hub cavity of the steering wheel. Continue to Step 26.

- For JL vehicles, position the DAB close enough to the steering wheel to access the steering wheel wire harness connectors to the DAB inflator initiators.

- For JL vehicles, connect the clockspring pigtail wire connectors to the airbag inflator initiator connector receptacles by pressing straight in on the connector insulator. Be certain to engage each keyed and color-coded connector to the matching connector receptacle. Be certain that each connector is fully engaged in its receptacle, then push the connector lock straight into the connector to lock it in place.

- For JL vehicles, carefully position the DAB to the steering wheel hub cavity while tugging lightly upward on the clockspring pigtail wires for the airbag and tucking the wires to the steering wheel. Be certain that none of the steering wheel wiring is pinched between the airbag housing or the horn switch and the steering wheel armature.

- For JL vehicles, using both hands, push firmly and evenly on both sides of the DAB trim cover until you can line the bolts up to the DAB. Install and tighten the bolts to the proper 9 N·m (80 in. lbs.).

- For JL vehicles, install the two access panel closeouts on the steering wheel near each of the two horizontal spokes.

- Do not connect the battery negative cable at this time. Continue with Section Supplemental Restraint System (SRS) Verification Test.

B. Replace DT Steering Column

WARNING: Before servicing the steering column the airbag system must be disarmed. Failure to do so may result in accidental deployment of the airbag and possible personal injury.

WARNING: When an undeployed airbag module is to be removed from the vehicle, first disconnect the battery ground cable and isolate it. Allow the system capacitor to discharge for a minimum of two minutes before starting any removal.

CAUTION: Anytime the Steering Column Control Module (SCCM) is mounted on the steering column the steering shaft must be kept from turning or else SCCM damage will occur. Some vehicles do not have an internal lock mechanisms, so the steering column shaft must be preventing from rotating through use of a suitable tool.

NOTE: In case of replacing steering column, connect a scan tool to initialize the steering angle sensor.

REMOVAL

- Disconnect and isolate the negative battery cable(s).

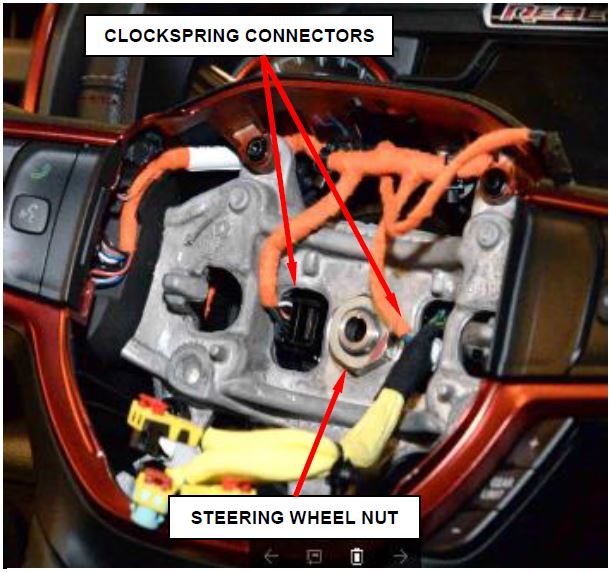

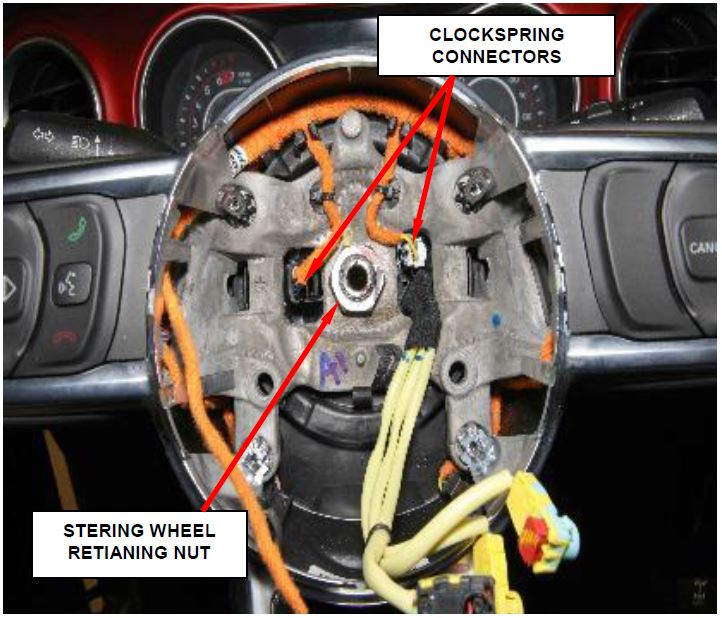

- Disconnect the Clockspring electrical connectors (Figure 7).

- Remove and DISCARD the steering wheel retaining nut and remove the steering wheel (Figure 7).

Figure 7 – Steering Wheel Removal

- Remove the instrument cluster bezel (Figure 8).

Figure 8 – Instrument Cluster Bezel

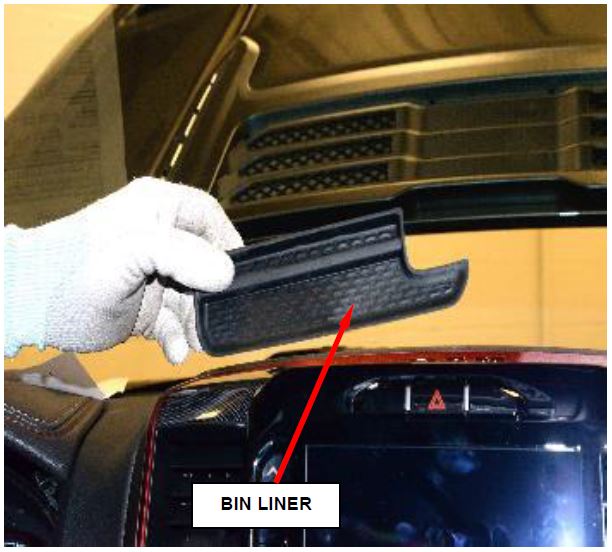

- Remove the center bezel bin liner (Figure 9).

Figure 9 – Bin Liner

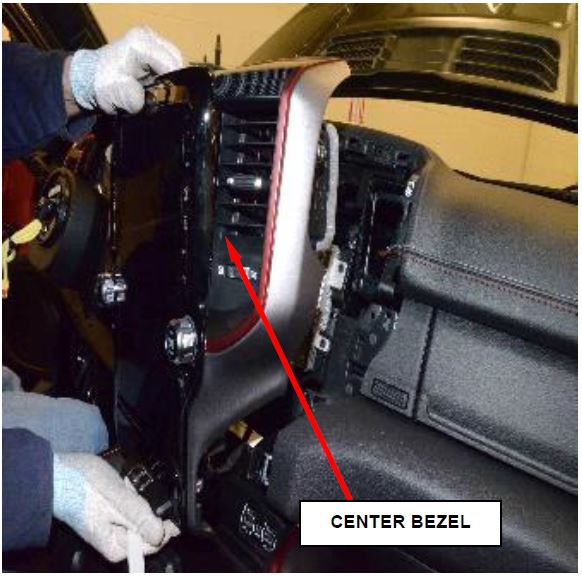

- Remove the center bezel fasteners.

- Remove the center bezel from the instrument panel (Figure 10).

- Disconnect the center bezel electrical connectors.

Figure 10 – Center Bezel

- Remove the headlamp switch bezel (Figure 11).

Figure 11 – Headlamp Switch Bezel

- Remove the steering column opening cover (Figure 12).

- Release The data link connector and the hood release handle.

Figure 12 – Steering Column Opening Cover

- Remove the Electronic Shift Module (ESM) trim bezel (Figure 13).

- Remove the four ESM fasteners and remove the ESM.

- Disconnect the ESM electrical connectors.

Figure 13 – ESM Trim Bezel

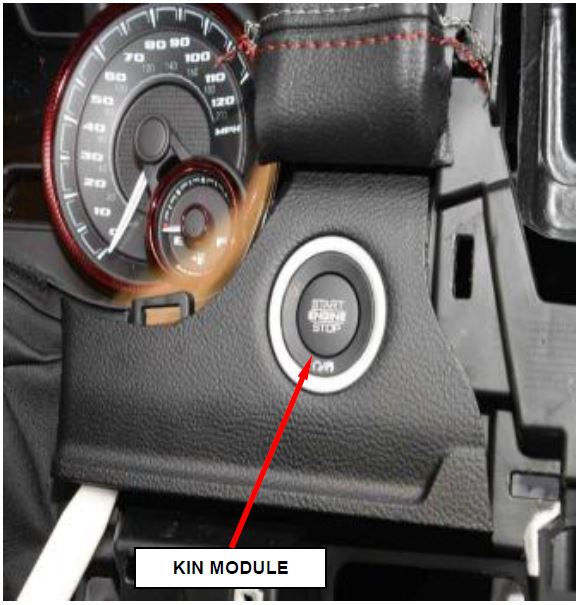

- Remove the KIN module (Figure 14).

- Disconnect the KIN electrical connector.

Figure 14 – KIN Module

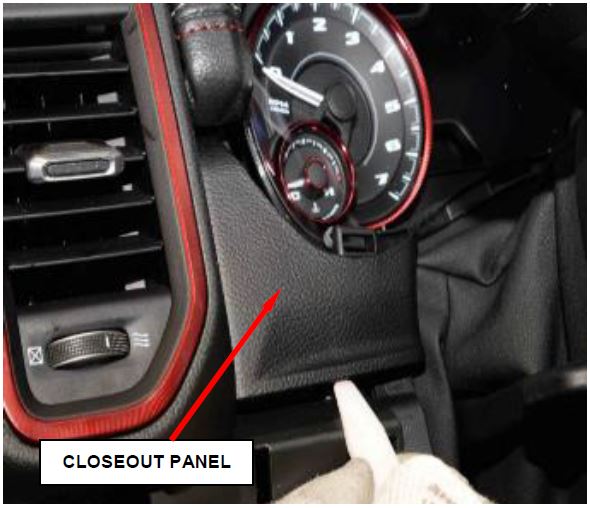

- Remove the left instrument cluster closeout panel (Figure 15).

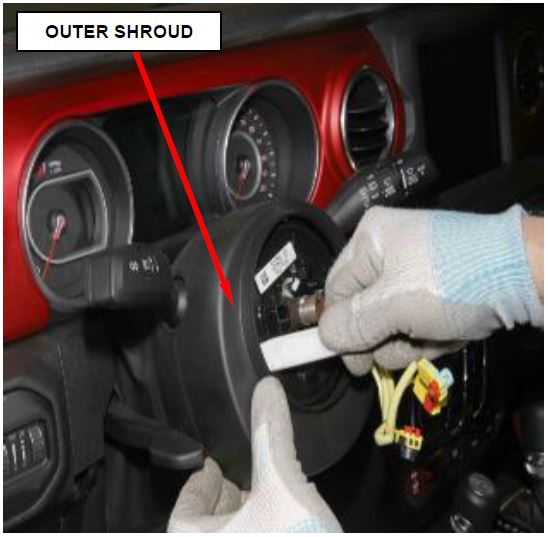

- Remove the outer shroud.

Figure 15 – Left Cluster Closeout Panel

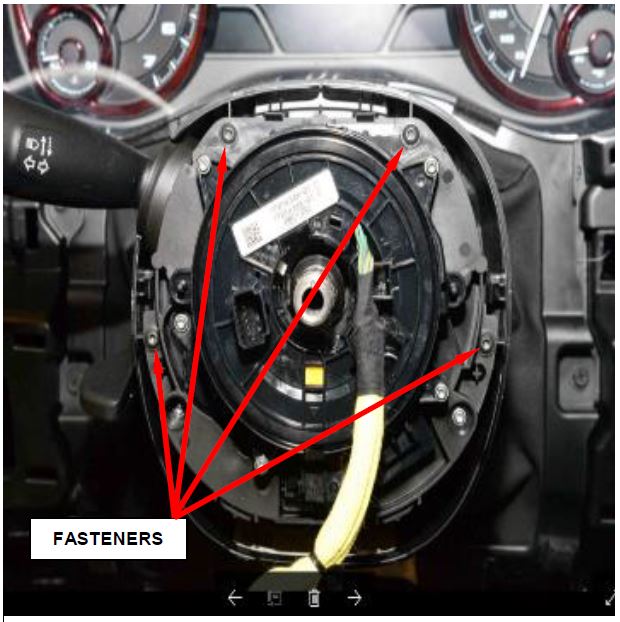

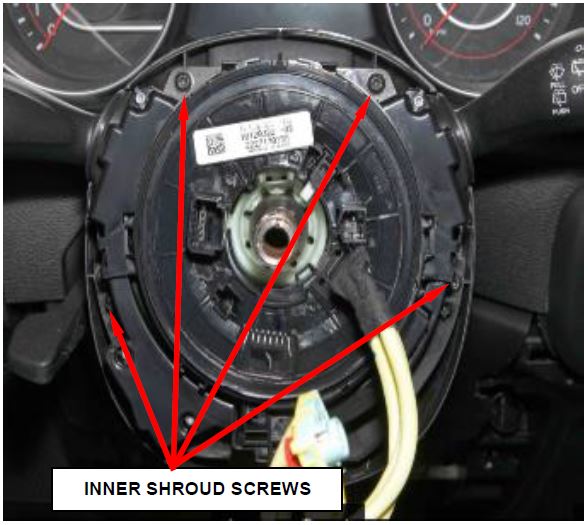

- Remove the Steering Column Control Module (SCCM) (Figure 16).

a. Remove four inner shroud fasteners (Figure 16).

b. Loosen the SCCM upper set screw and lower clamp bolt.

- Remove the SCCM electrical connector.

- Remove the SCCM.

Figure 16 – Inner Shroud Fasteners

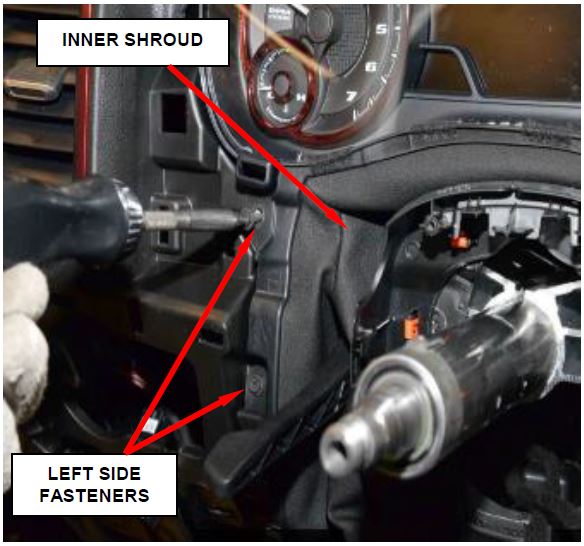

- Remove the inner shroud and connectors (Figure 17).

Figure 17 – Inner Shroud

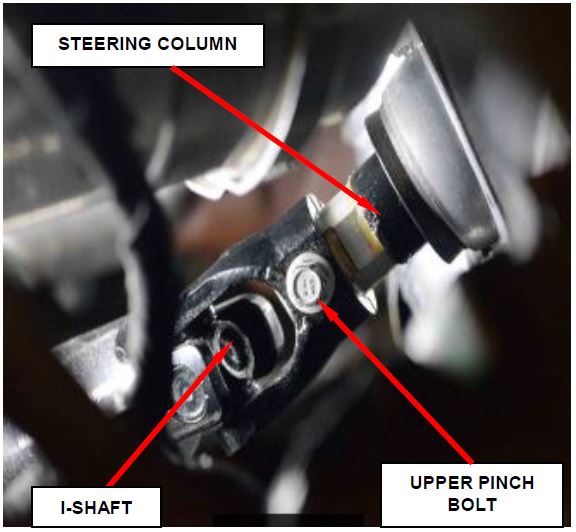

- Remove and DISCARD the intermediate shaft upper pinch bolt (Figure 18).

- Remove the intermediate shaft from the steering column shaft.

Figure 18 – Upper Pinch Bolt

- Disengage the wire harness routing clip from the steering column.

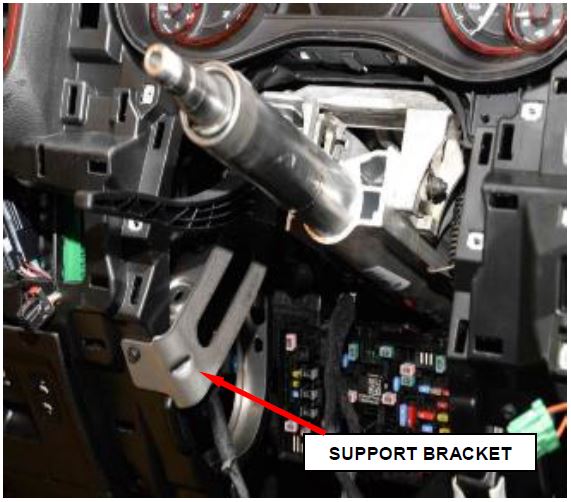

- Remove the steering column support bracket (Figure 19).

Figure 19 – Steering Column Support Bracket

- Remove the Power Distribution Center (PDC) (Figure 20).

Figure 20 – PDC

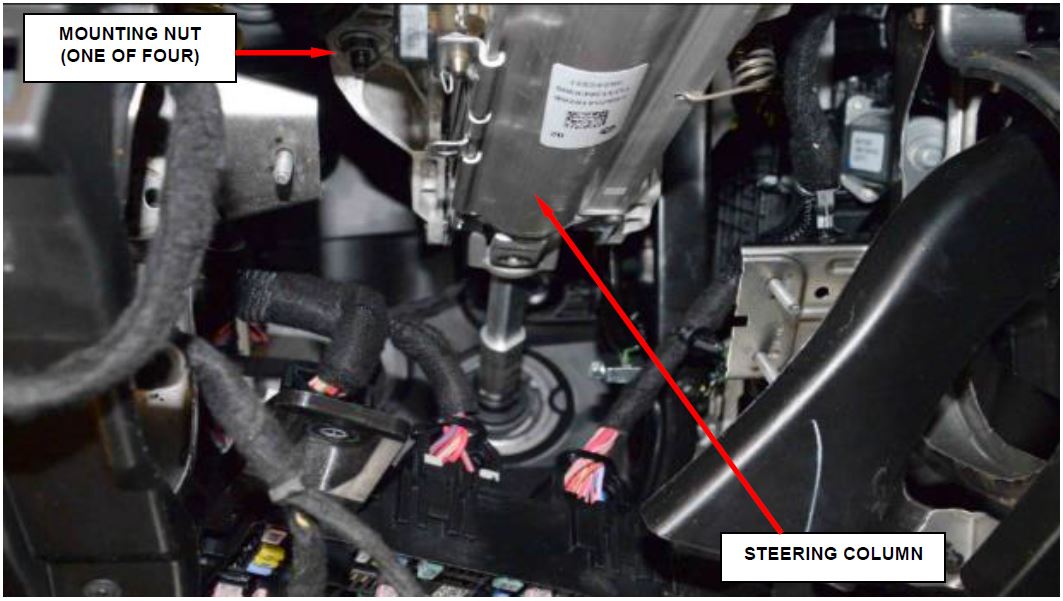

- Remove the four steering column nuts and retain the instrument panel bracket (Figure 21).

- Pull the steering column shaft through bulkhead pass through then remove and DISCARD the steering column (Figure 21).

Figure 21 – Steering Column

INSTALLATION

- Position the NEW steering column in the vehicle.

- Slide the steering shaft through the bulkhead pass through.

- Place the instrument panel bracket over the left rear steering column stud and install the four steering column nuts then tighten to 28 N·m (21 ft. lbs.).

- Engage the wire harness routing clip to the steering column.

- Install the intermediate shaft to the steering column shaft.

- Install a NEW intermediate shaft upper to lower pinch bolt and tighten to 50 N·m (37 ft. lbs.).

- Install the Power Distribution Center (PDC).

- Install and tighten the instrument panel bracket screw securely.

- Install the inner shroud and gap hider.

- Install the Steering Column Control Module (SCCM) and tight all fasteners securely. Connect the electrical connectors.

- Install the outer steering wheel shroud.

- Connect the KIN module electrical connector and install the KIN module.

- Connect the ESM electrical connector and install the ESM.

- Install the ESM bezel.

- Install the data link connector and hood release.

- Install the lower instrument panel cover and fasteners.

- Connect the headlamp switch and install the headlamp switch bezel.

- Connect the center bezel electrical connectors then install the center bezel.

- Install the center bezel fasteners and bin liner.

- Install the instrument panel bezel.

- Install the cluster bezel.

- Install the left cluster closeout panel.

- Install the steering column opening cover.

- Install the outer steering wheel shroud.

- Install the steering wheel.

a. Slide the steering wheel over the splined steering column shaft.

NOTE: Be certain that the steering wheel nut is tightened to the proper torque specification to ensure proper clockspring operation.

b. Install the NEW steering wheel nut and tighten to the proper 50 N·m (37 ft. lbs.).

c. Connect the wire harness connectors.

- Install the driver’s airbag.

a. Position the DAB close enough to the steering wheel to connect the steering wheel wire harness connectors to the DAB inflator initiators.

b. Connect the clockspring pigtail wire connectors to the airbag inflator initiator connector receptacles by pressing straight in on the connector insulator. Be certain to engage each keyed and color-coded connector to the matching connector receptacle. Be certain that each connector is fully engaged in its receptacle, then push the connector lock straight into the connector to lock it in place.

c. Carefully position the DAB to the steering wheel hub cavity while tugging lightly upward on the clockspring pigtail wires for the airbag and tucking the wires in the upper hub cavity of the steering wheel. Be certain that none of the steering wheel wiring is pinched between the airbag housing or the horn switch and the steering wheel armature.

d. Using both hands, push firmly and evenly on both sides of the DAB trim cover until both ends of the spring retainer have snapped in place under the hooks within the hub cavity of the steering wheel.

- Do not connect the battery negative cable at this time. Continue with Section D. Supplemental Restraint System (SRS) Verification Test.

C. Replace JL Steering Column

REMOVAL

- Position front wheels straight ahead.

CAUTION: Steering column module is centered to the vehicles steering system. Failure to keep the system and steering column module centered and locked/inhibited from rotating can result in steering column module damage.

NOTE: Some vehicles may not be equipped with an internal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of locking the steering wheel for service will have to be used.

- Disconnect and isolate the negative battery cable(s).

- Position wheels to into straight position

- Disconnect clockspring electrical connectors (Figure 22)

- Remove and DISCARD the steering wheel retaining nut. Remove the steering wheel (Figure 22).

Figure 22 – Remove Steering Wheel Nut

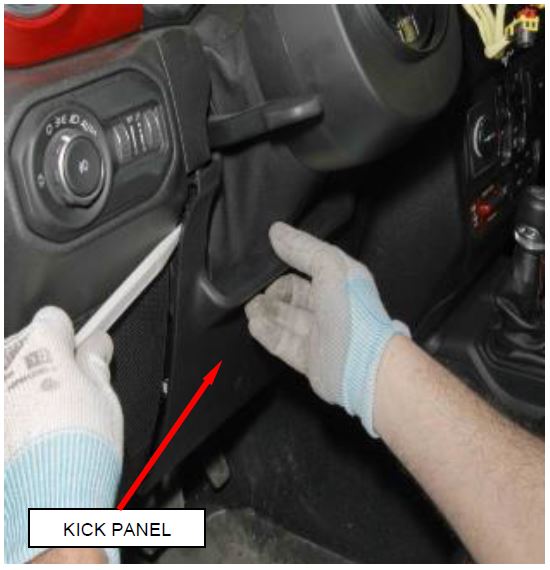

- Remove the steering column kick panel cover (Figure 23).

Figure 23 – Kick Panel

- Remove the outer steering column shroud (Figure 24).

Figure 24 – Outer Shroud

- Remove and save the four inner shroud fasteners from the SCCM (Figure 25).

Figure 25 – Inner Shroud Screws

- Loosen the SCCM upper set screw and lower clamp bolt.

- Disconnect the SCCM electrical connectors and remove the SCCM.

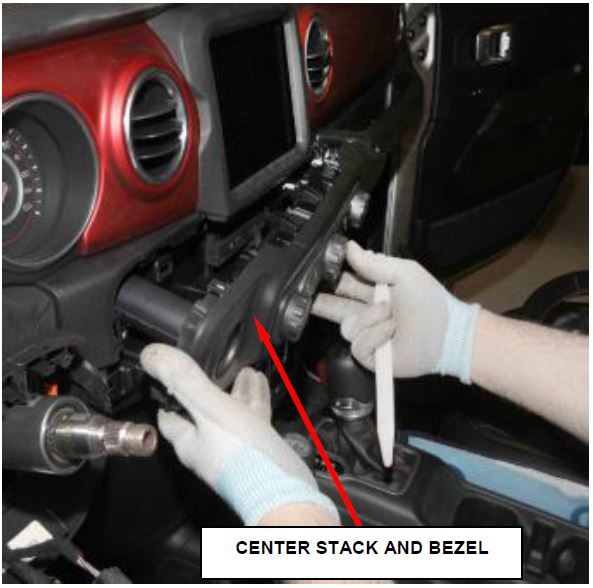

- Remove the center stack bezel and position to the side (Figure 26).

Figure 26 – Center Stack

- Remove the inner steering column shroud and gap hider assembly (Figure 27).

Figure 27 – Inner Shroud and Gap Hider Assembly

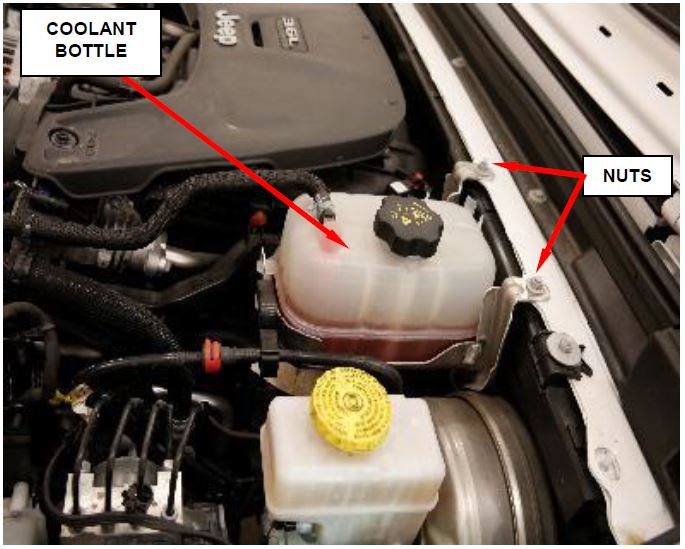

- Removing the coolant bottle will provide access to the intermediate shaft to steering column shaft connection (Figure 28).

Figure 28 – Coolant Bottle

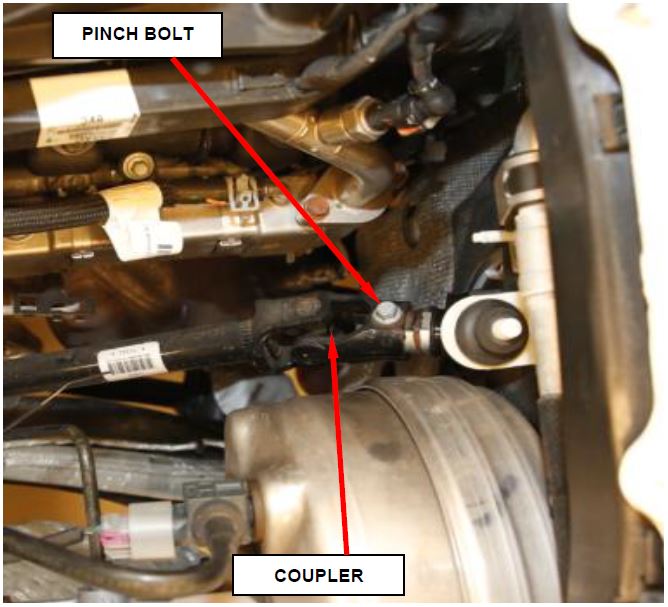

- Remove and DISCARD the intermediate shaft coupler pinch bolt from the steering column end of the shaft (Figure 29).

- Disconnect the upper end of the steering intermediate shaft coupler from the steering column shaft (Figure 29).

Figure 29 – Pinch Bolt

- Release the steering column harness mounting clip.

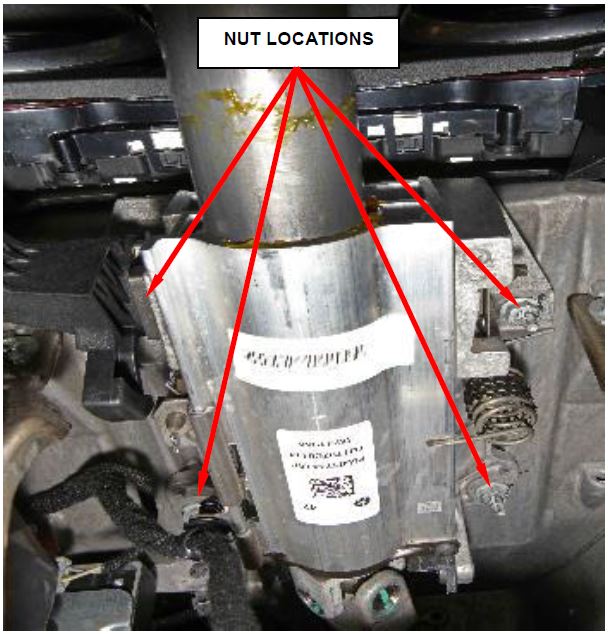

- Remove and save the four steering column mounting nuts (Figure 30).

- Remove and DISCARD the steering column.

Figure 30 – Mounting Nuts

INSTALLATION

- Carefully guide the NEW steering column shaft through the bulkhead.

- Position the steering column mounting holes over the steering column studs and start the four steering column nuts finger tight.

CAUTION: Lower nuts must be installed and tightened first then the upper nuts in order to prevent damage to the capsules.

- Reconnect the upper end of the intermediate shaft to the steering column shaft

- Install a NEW upper pinch bolt and tighten to 34 N·m (25 ft. lbs.).

- Install the coolant bottle.

- Tighten the four steering column nuts to the proper 27 N·m (20 ft. lbs.).

- Secure the wiring harness routing clip to the steering column.

- Install the steering column opening cover.

- Install the center stack bezel.

- Install the inner steering column shroud.

- Tighten the SCCM upper bolt and lower the clamp bolt securely.

- Install the four SCCM and secure the fasteners.

- Install the outer steering column shroud.

- Install the steering column kick panel cover.

- Install the steering wheel.

a. Slide the steering wheel over the splined steering column shaft.

NOTE: Be certain that the steering wheel nut is tightened to the proper torque specification to ensure proper clockspring operation.

b. Install the NEW steering wheel nut and tighten to the proper 50 N·m (37 ft. lbs.).

c. Connect the wire harness connectors.

- Install the driver’s side air bag.

a. Position the DAB close enough to the steering wheel to access the steering wheel wire harness connectors to the DAB inflator initiators.

b. Connect the clockspring pigtail wire connectors to the airbag inflator initiator connector receptacles by pressing straight in on the connector insulator. Be certain to engage each keyed and color-coded connector to the matching connector receptacle. Be certain that each connector is fully engaged in its receptacle, then push the connector lock straight into the connector to lock it in place.

c. Carefully position the DAB to the steering wheel hub cavity while tugging lightly upward on the clockspring pigtail wires for the airbag and tucking the wires to the steering wheel. Be certain that none of the steering wheel wiring is pinched between the airbag housing or the horn switch and the steering wheel armature.

d. Using both hands, push firmly and evenly on both sides of the DAB trim cover until you can line the bolts up to the DAB. Install and tighten the bolts to the proper 9 N·m (80 in. lbs.).

e. Install the two access panel closeouts on the steering wheel near each of the two horizontal spokes.

- Do not connect the battery negative cable at this time. Continue with Section Supplemental Restraint System (SRS) Verification Test.

D. Supplemental Restraint System (SRS) Verification Test

NOTE: During the following test, the negative battery cable remains disconnected and isolated during steps 1 and 2 of the Supplemental Restraint System (SRS) Verification Test.

NOTE: The wiTECH scan tool must be used to perform this recall. The wiTECH software is required to be at the latest release level before performing this procedure.

- Connect the wiTECH micro pod II to the vehicle data link connector located under the steering column.

- For vehicles equipped with a keyed ignition switch, turn the ignition switch to the “ON” position and exit the vehicle then continue with Step 4.

- For vehicles equipped with keyless ignition node, check to be certain that nobody is in the vehicle then connect the battery negative cable(s) and turn the ignition switch to the “ON” position then continue with Step 5.

- Check to be certain that nobody is in the vehicle, then connect the battery negative cable(s).

- Install the airbag module fuses, if applicable.

- Open the wiTECH Diagnostic application.

- Starting at the “Select Tool” screen, select the row/tool for the wiPOD device you are using, then select “Next”.

- Enter your “User id” and “Password”, then select “Finish”.

NOTE: If wiTECH is unable to identify the connected vehicle, click on the Launch DRB III button and use the DRB III Emulator tool.

- Clear all DTC’s in all modules using either the wiTECH or the DRB III mode.

NOTE: Any active Diagnostic Trouble Codes (DTC’s) may require an additional key cycle from “ON” to “OFF” to change DTC status from

“active” to “stored”.

- Turn the ignition switch to the “OFF” position for about 15 seconds, and then back to the “ON” position. Observe the airbag indicator in the instrument cluster.

- The airbag indicator in the instrument cluster should illuminate for six to eight seconds, and then go out. This indicates that the SRS is functioning normally and that the repairs are complete. Turn the ignition to the “OFF” position.

- If the airbag indicator fails to light or the light and stays ON, there is still an active SRS fault or malfunction. Refer to the appropriate diagnostic information to diagnose the problem.

- Close the hood and remove the wiTECH micro pod II.

- Return the vehicle to the customer.

SEOCONTENT-START

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments.

Use one of the following labor operation numbers and time allowances:

| Labor Operation Number | Time Allowance | |

|---|---|---|

| Inspect Steering Column | 19-V2-91-81 | 0.2 hours |

| Inspect and Replace Steering Column (DT) | 19-V2-91-82 | 1.1 hours |

| Inspect and Replace Steering Column (JL) | 19-V2-91-83 | 0.7 hours |

| Special Service LOP | ||

| Rent Special Tool | 95-85-26-50 | up to Documentation may be required |

| Floor Plan Reimbursement | 95-95-95-97 | Calculate See Below |

Floor Plan Reimbursement represents the vehicle’s average daily allowance (see table below) multiplied by the number of days the vehicle was in dealer inventory and not available for sale. This reimbursement is limited to the number of days from the date of the stop sale to the date that the remedy was made available. Note: If the vehicle was received by your dealership (KZX date) AFTER the stop sale date, you will use the KZX date instead of the stop sale date. For this Recall, the stop sale was initiated on 03/21/2019 and the remedy was made available on 03/29/2019, therefore, the number of days cannot exceed 8 days.

| Vehicle | Average Daily Allowance |

| 2019 (JL) Jeep Wrangler | |

| 2019 (DT) Ram 1500 Pickup |

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

This notice applies to your vehicle,

[Model Year and Model] VIN XXXXXXXXXXXXXXXXX

V29/NHTSA 19V-201

LOGO

VEHICLE PICTURE

YOUR SCHEDULING OPTIONS

- RECOMMENDED OPTION Call your authorized Chrysler / Dodge

/ Jeep® / RAM Dealership

/ Jeep® / RAM Dealership - Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can confirm part availability and help schedule an appointment

- Visit recalls.mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App.

QR Code

Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above.

DEALERSHIP INSTRUCTIONS

Please reference Safety Recall V29.

IMPORTANT SAFETY RECALL

Dear [Name],

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

FCA has decided that a defect, which relates to motor vehicle safety, exists in certain [2019 (JL) Jeep® Wrangler and 2019 model year (DT) RAM 1500] vehicles.

It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers.

WHY DOES MY VEHICLE NEED REPAIRS?

The steering column on your vehicle [1] may have been built with an improperly machined steering column stub shaft that may break, and could allow the steering wheel to detach from the steering column. A steering wheel separation from the steering column may result in a loss of steering control, and can cause a vehicle crash without prior warning, as well as a compromised driver front impact safety system, increasing the risk of driver injury in a vehicle crash.

HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE?

FCA will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will inspect, and if necessary replace, steering column assemblies in all affected vehicles. The estimated repair time is two hours. In addition, your dealer will require your vehicle for proper check-in, preparation, and check-out during your visit, which require more time. Your time is important to us, so we recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership.

TO SCHEDULE YOUR FREE REPAIR,

CALL YOUR CHRYSLER, DODGE, JEEP OR RAM DEALER TODAY

WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED?

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed.

We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Assistance/Field Operations

FCA US LLC

Mr. Mrs. Customer

1234 Main Street

Hometown, MI 48371

[1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information.

[2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-4249153), or go to safercar.gov.

[2] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement.

Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

SEOCONTENT-END

2 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

| JEEP | WRANGLER | 2019 |

| RAM | 1500 | 2019 |

9 Associated Documents

Defect Notice 573 Report

RCLRPT-19V201-1398.PDF 214.619KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V201-9984.pdf 1755.354KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 03/21/2019 New Safety Recall Advanced Communication – V29

RCMN-19V201-2070.pdf 100.542KB

Loading...

Loading...

Recall Acknowledgement

RCAK-19V201-8300.pdf 245.192KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-19V201-5551.pdf 517.418KB

Loading...

Loading...

Recall Quarterly Report #1, 2019-2

RCLQRT-19V201-1435.PDF 211.136KB

Loading...

Loading...

ISSUED Renotification Notice

RCRN-19V201-0402.pdf 136.128KB

Loading...

Loading...

Recall Quarterly Report #2, 2019-3

RCLQRT-19V201-6588.PDF 211.233KB

Loading...

Loading...

Recall Quarterly Report #3, 2019-4

RCLQRT-19V201-4371.PDF 211.321KB

Loading...

Loading...

Latest Recalls Documents

- [Pro OBD2 Scanner] - BlueDriver is the easiest way to scan and understand your vehicle like a professional mechanic. Read and clear your car’s trouble codes and check engine light.

- [Read & Clear All The Codes] - BlueDriver's enhanced vehicle diagnostics gives you access to information normally available only to mechanics on their OBD2 scan tools. Now you can read and clear ABS, Airbag, SRS, TPMS codes, and many more.

- [Get The Right Fix & View Live Data] - Much more than a car code reader, BlueDriver is a diagnostic tool. You’ll get unlimited repair reports with possible causes and fixes, plus real-time health monitoring while you drive with the live data feature.

- [Wireless & Bluetooth Enabled] - Say goodbye to wires. BlueDriver connects with Bluetooth via your phone/tablet to a sensor that plugs into your car's OBDII port. Get all of the capabilities of an expensive code reader & scan tool without any annoying wires.

- [User-Friendly App and Repair Videos] - BlueDriver gives you more ways to scan and fix your vehicle. Our iOS & Android app connects you to a large database of repair videos with step-by-step directions of repairs.

- [Easy to Use--Work out of box] + [FOXWELL 2025 New Version] FOXWELL NT604 Elite scan tool is the 2025 new version from FOXWELL, which is designed for those car owners who want to figure out the cause issue before fixing the car problem via scanning the most common systems like abs srs engine and transmission.The NT604 Elite diagnostic tool comes with latest software, which can be used out of box. No need to waste time to download the software first.

- [Affordable] + [Reliable Car Health Monitor] Will you be confused what happen when the warning light of abs/srs/transmission/check engine flashes? Instead of taking your cars to dealership, this foxwell scanner will help you do a thorough scanning and detection for your cars and pinpoint the root cause. It will t-urn off the warning light car after the problem is fixed.👉TIPS: Airbag crash/collision data can NOT be cleared even you replace the new airbag.

- [5 in 1 Diagnostic Scanner] Compared with those auto scanners (50-100), NT604 Elite code scanner not only includes their OBDII diagnosis but also it can be an abs/srs scanner, transmission and check engine code reader. When it’s an odb2 scanner, you can use it to check if your car is ready for annual test through I/M readiness menu. In addition, live data stream, built-in DTC library, data play back and print, all these features are a big plus for it. Note: doesn't support maintenance function.

- [Fantastic AUTOVIN] + [No extra software fee] Through the AUTOVIN menu, this NT604 Elite car scanner allows you to get your V-IN and vehicle info rapidly, no need to take time to find your V-IN and input one by one. What's more, the NT604 Elite abs srs scanner supports 60+ car makes from worldwide (America/Asia/Europe). You don’t need to pay extra software fee.

- [Solid protective case KO plastic carrying bag] + [Lifetime update] Almost all same price-level obd scanner diagnostic tool only offers plastic bag to hold on the scanner.However, NT604 Elite automotive scanner is equipped with solid protective case, preventing your obd2 scanner from damage. Then you don’t need to pay extra money to buy a solid toolbox.

- [Brand-New ArtiDiag500] We've got everything you're looking for! Forget basic OBD2 scanners; TOPDON's ArtiDiag500 car scanner offers more. The all-new ArtiDiag500 not only includes full OBD2 functions and 4-system diagnostics but also provides DIYers with 6 maintenance services. The brand-new, cost effective AD500 is back in full swing!

- [4-System Diagnostics] DIY enthusiasts, take notice! Will these 4-system diagnostics be the treasure you've been seeking? The ArtiDiag500 code reader offers in-depth testing for the engine, transmission, ABS, and SRS systems, reading fault codes and data streams. It also visualizes real-time data in chart form, simplifying complex data for storage and future playback, aiding DIY users in problem detection.

- [6 Reset Functions] Hey, hang tight for a moment. With these 6 reset functions, the ArtiDiag500 has got you covered. It offers throttle adaptation along with reset capabilities for Oil, SAS, TPMS, BMS, and EPB. Seamlessly aligning the throttle, battery, tires, and brake pads with your vehicle, it also adjusts the steering angle and turns off the oil light. Looking to restore your car to its original condition? Look no further than the ArtiDiag500.

- [Multiple Functions] The Smart AutoVIN of this TOPDON OBD2 scanner keeps track of your manual selections for vehicle make, model, and year and directs you to the suitable diagnostics. Max 4 Live Data streams integrated for much easier data processing. Diagnostic feedback online with this diagnostic tool to help you get tough repair operations well-completed. Real-time car battery voltage monitoring identifies probable vehicle defects.

- [Global Support] Rest assured about compatibility with your vehicle and language – ArtiDiag500 currently supports 67+ car brands, 10,000+ models, covering most vehicles worldwide, and is available in 12 languages. Whether it's for your car or preferred language, there's an ideal choice for you. Plus, it's fully compatible with Android 11 for smoother use.

- 【Great Ideal For Every Car Owner】Prefect choice for your father, husband, brother or boyfriend. EVERY CAR OWNER WILL NEED IT! Also, the lifetime update is provided for more vehicle coverage, bug fixes. SAVE AT LEAST $1000+ PER YEAR!Get LAUNCH CRP123 V2.0 Elite car diagnostic scanner and give your lover a surprise!*R each us to Get the Extra Gifts :Protective Case Storage Bag.

- 【2025 Newly Added 3 Reset Functions】CRP123 V2.0 obd2 scanner with upgrades it offers Throttle Adaptation,Oil Reset and SAS Reset functions for FREE now!! Optimize your engine performance with Throttle Adaptation, reset your oil life system with ease to save time and money on maintenance, and enhance your vehicle's handling and safety with SAS Reset.Covering more daily repairs,become the most cost-effective product in its price range,save your time and money!

- 【 Read & Clear/Reset Engine/ABS/SRS/Transmission Diagnostic Scan Tool 】LAUNCH CRP123 V2.0 OBD2 Scanner can test Engine, Transmission, ABS and Airbag four systems, also reads and resets code, displays data stream graphic, stores and playbacks dynamic data stream,helps to quick analysis and diagnosis.

- 【 Error Fault Code Reader】Except the full 10 modes OBD2 diagnostic functions like, retrieving I/M readiness, Freeze Frame Data, Read Dynamic Data stream and V-ehicle Information, O2 Sensor Test, EVAP Test of F-uel Tank System (Mode 8) and Advanced On-board Monitoring (Mode 6), launch crp123 v2.0 obd2 scanner can not only reveal what error codes your car is producing, but also erase your v-ehicle’s check engine light after problem fixed, the DTC help and explanation also tell you the exact problem.

- 【 Live Data Graphing + Read/Record/Playback Data stream + Print diagnostic data 】Live Data Graphing,more intuitive to know your vehicle’s problem.Large size Color Screen ;Print Function:Print the diagnose result easily; with user manual and register & update tutorial video uploaded in the link by us,you can Look up it anytime by ONE-CLICK.

- [ABS Diagnosis] - Quickly identify and resolve ABS-related issues, including sensor faults (such as wheel speed sensors), wiring problems (faulty circuits or connectors within the ABS system), or ABS pump failures (malfunctions in the ECU controlling the ABS). Ensure proper system operation, restore optimal braking performance, and clear any warning lights.

- [SRS Diagnosis] - Quickly detect the airbag ECU itself, airbag sensor failure, airbag system plug disconnection or poor contact, seat belt sensor failure, or system error, etc, to ensure that the SRS (Supplemental Restraint system) is working properly. After repair, reset the system to clear the warning light and restore full safety performance. NOTE: It cannot reset Airbag crash or transmission codes.

- [Full OBD2 Function] - Read and clear trouble codes for all OBD2 systems, including show real-time data, freeze frame data, I/M Readiness, DTC lookup, test results for o-xygen sensor, On-board monitor test, request vehicle information, component test, modules present and e-vap test. Allowing you to quickly identify and troubleshoot vehicle issues.

- [AutoVIN Technology] - It simplifies diagnostics by automatically identifying the vehicle’s model and configuration, eliminating the need for manual input, and ensures accurate diagnostics by applying the correct data and algorithms, reducing errors caused by manual entry. Improves efficiency and streamlines the diagnostic process.

- [ABS Auto Bleeding] - Helps bleed your vehicle's Anti-lock Braking System (ABS), removing air from the brake lines to ensure optimal brake performance. It helps prevent brake issues such as spongy pedals, inconsistent braking, and reduced stopping power, and enhances vehicle safety by ensuring the ABS system is working properly, especially during critical driving situations. NOTE: It’s not compatible with vehicles that only support manual bleeding.

- [Transform Your Car Care Experience] - With BLCKTEC, instantly become your own professional mechanic. Effortlessly read and clear your car’s trouble codes and check engine light, ensuring your vehicle stays in top condition.

- [Empower Yourself with Comprehensive Diagnostics] - Unlock the full potential of your vehicle with the BLCKTEC 430. Access detailed diagnostics previously exclusive to professional mechanics’ OBD2 scan tools, including ABS, Airbag, SRS, TPMS codes, and beyond, right at your fingertips.

- [Drive with Confidence] - The BLCKTEC 430 is more than just a car code reader; it's your personal vehicle health advisor. Receive tailored repair reports with potential causes and verified solutions for your specific make and model, guiding you to the right fix every time.

- [Seamless Connectivity, Ultimate Convenience] - Experience the freedom of wireless diagnostics with this portable car scanner. Easily connect via Bluetooth to our intuitive sensor and enjoy all the functionalities of high-end scan tools without the clutter of wires, directly from your smartphone or tablet. To connect the tool to the App, please DO NOT go to device's Bluetooth settings, instead, open RepairSolutions2 App and follow the instructions on the App to pair the BLCKTEC 430.

- [DIY Repairs Made Easy] - Navigate car maintenance with ease using our premium app. Access a vast library of easy-to-follow repair videos, guiding you through each step of the repair process, compatible with both iOS & Android devices.

- 9 Reset Services Car Scanner: TOPDON obd2 scanner AD600S is the upgrade version of TOPDON AD600, AD500 and AD500S. The latest version adds 1 reset function again. Except for OIL RESET, BRAKE RESET, TPMS RESET, Throttle Adaptation, SAS RESET, BMS RESET, ABS BLEEDING, DPF RESET, it add the Injector Coding, more practical reset functions than TOPDON AD600 and AD500. For the cost you' re getting value from this handy car scanner to reset systems. *Function menu varies by vehicle’s specifics

- Recommended by Youtuber Samcrac: 4 Systems Diagnostic Tool, AUTOAUTH FOR FCA GATEWAY ACCESS: This is an OBDII scanner and 4 systems diagnostic tool made for home mechanics, DIYers, and professionals. You can access AT/ENG/ABS/SRS fault codes to find the right troubleshooting procedure, and diagnose with full 10 OBD2 test modes to fix most of emission issues. Give your aging cars satisfying routine maintenance to avoid costly repairs, a breakdown, or even a crash. *DOESN'T WORK WITH 5G

- No extra software fee + One-click Free Updates + 32G memory: The touch-sensitive screen on this scan tool makes operation much easier than the simple button-based OBD2 code readers. The icons are clear and its 5” color screen with high resolution will leave you with no trouble interpreting results in a dark garage. One-click updates over Wi-Fi will keep the software current and the coverage addition constant. Android 11.0 ensures lightning-fast bootup and processing

- Powerful Compatibility + Work on 90 Vehicle Brands: Most OBD2 scanners work with vehicles manufactured after 2001, but TOPDON ArtiDiag600S compatible with OBDII-equipped vehicles built after 1996, and it works on more than 90 Vehicle Brands.It supports Diesel (12v only), gasoline, 12V passenger car, pickup, light-duty truck, SUV, minivans, compatible with OBD2/EOBD/JOBD&CAN/CAN-FD protocols.*Menus vary by make, model, and year of gasoline or diesel engine vehicle. Email us your VIN data

- Versatile Scan Tool+AUTO VIN+DTC Lookup: This OBD2 scanner has automatic VIN technology to identify the car without manual input. Live data display in text or 4-in-1 merged waveform graph, you can save, share, print, or email the overall inspection report for easier analysis. Inbuilt “Feedback” module provides customized repair suggestions from our certified professionals. Onboard DTC library saves your Google searching time when interpreting the error codes. AutoVIN doesn’t work on ALL cars

- 【Designed for Volkswagen(VAG) Cars Diagnostics】The VD500 OBD2 scanner is specifically designed to diagnose Volkswagen Group (Fits for VW/Audi/Skoda/ SEAT) 12-volt 16-pin vehicles, but can also be used with other 12-volt (non-Volkswagen) and light trucks (non-electric) vehicles manufactured in 1996 or later that are OBD II -compliant with standard 16-pin OBD II protocols (J1850 VPM, J1850PWM, ISO9141, KWP 2000 and CAN)

- 【Basic + Special Advanced Functions for VAG Vehicle】The ANCEL VD500 scan tool for vw can not only read and clear codes on engine, ABS, transmission, SAS (not all cars), ESP, TPMS and other systems, but also reset the oil, brake pad(epb service) and throttle position adaption. If you don't know how to do it, please con-tact us in time. Include your car model, year and the function you want to do

- 【Plug and Play, No Complex Connection】The ANCEL VD500 is truly plug-and-play—no complicated networking or batteries required. Simply connect it and use it anywhere in your car, anytime. Fast, easy, and convenient

- 【Full Access, No Hidden Costs】Unlike other detectors that charge extra for features, the ANCEL VD500 is 100% no extra additional charges, with no hidden costs. The full functionality is accessible, and the system upgrade is included, a favorite choice among customers

- 【Wide Compatibility for Volkswagen Cars】The VD500 diagnostic scanner for audi offering for Volkswagen vehicles covers the following vehicles: fits for VW (CC, EOS, Golf, GTI, Jetta, Passat, Phaeton, Polo, Rabbit, Sharan, Tiguan, Touran, Touareg); fits for Audi (A3, A4, A6, A7, A8, A5, Q3, Q5, Q7, R8, RS3, TT, RS, RS5, S4, S6); fits for Skoda (Octavia, Rapid, Yeti, Kodiaq, Fabio, Superb); fits for SEAT (Leon, Ateca, Ibiza, Altea, Cushion, Cord, Alhambra) Diagnostics

- 【ENHANCED DIAGNOSTIC SCAN TOOL WITH ABS/SRS/ECM/TCM SYSTEMS】 The XpertAuto S515 OBD2 scan diagnostic tool helps diagnose issues with ABS, SRS, ECM, and TCM systems. This car diagnostic scan tool reads and clears error codes, reads data streams, retrieves ECU info,and quickly locates ABS, SRS, ECM, TCM problems

- 【8 HOT RESET SERVICES】The XpertAuto S515 professional level car code reader and reset tool offers 8 hot reset services, including oil, airbag, SAS, EPB, ETS, ABS bleed, DPF regeneration and battery reset. This car code reader is perfect for thoughtful and attentive service, covering everything from routine maintenance and warning light removal to auto part replacement and more

- 【PROFESSIONAL-GRADE OBD2 SCANNER】 The car scanner diagnostic tool delivers professional-grade functionality at a consumer price. It covers all the essentials: Read Codes, Erase Fault Codes, MIL Fault Indicator Light, Live Data, EVAP System Test, View Freeze-Frame, Vehicle Info, I/M Readiness, and DTCs Look-up, ensuring accurate diagnosis and peace of mind

- 【AUTOSEARCH VIN - SCREENSHOT & RECORDING】 The Vehicle Code Reader features intelligent Auto VIN technology for fast and accurate one-touch vehicle identification. It scans ECUs, collects vehicle information and performs diagnostics on selected systems. This car diagnostic tool comes with unique screenshot and video recording function, allowing you to save extensive data effortlessly

- 【MULTIPLE DISPLAY OF LIVE DATA】 The car diagnostic tool can display data streams through numbers, images, and a combination of both. It also allows comparison with historical data for a comprehensive view of your car's condition and changes at a glance. Car diagnostic reports can be easily saved, shared, printed, and emailed

- 【UPGRADE OF NT604-POWERFUL 5 RESETS】Wanna to do maintenance service for your car however the basic 4 system scanner tool can't do it? Then FOXWELL NT614 Elite-the upgraded version of nt604, was born for providing you with 5 special functions-ABS Bleeding/Oil Reset/SAS Calibration/EPB Reset/Throttle Reset. These functions are enough for your daily needs. No need to buy those 300-600 dollors obd2 scanner. Saving your unnecessary repair fee with FOXWELL nt614 car scanner diagnostic tool!

- 【ENGINE/ABS/SRS/TRANSMISSION CODE READER】Don't know what's wrong with your car when the warning light of ABS, transmission, SRS, Engine flashes? NT614 Elite obd2 scanner can pinpoint the problem components. It boasts many functions of engine, abs, srs and transmission such as read & erase fault codes and grapgh live data like engine temp, wheel speed sensor, read transmission temperature, etc. Compared with car repairs, using foxwell nt614 elite is more convenient and a-ffordable.

- 【Best Bang For Your Buck!-FOXWELL NT614 Elite】1. 2025 New software-faster than old one. 2. One click lifetime WIFI f-ree update, no need to use the annoying Micro SD card. 3. New Update-No need to register on the FOXWELL website before use, more convenient! 4. More intuitive viewing with new interface, you can find I/M, Battery Test, DTC Lookup directly.

- 【ABS BLEEDING OBD SCANNER】Do you always feel the brake pedal was slowly sinking to floor or it's loose after doing a complete front & rear brake job? And then you need to take more time than normal to stop your car, which is very dangerous. That's because when you open the brake system to replace components, air gets inside. To get a firm brake pedal, the air need to be removed by bleeding the brakes. NT614 Elite odb2 scanner can do ABS BLEEDING perfectly for your cars.

- 【SMART AUTOVIN & LIFETIME F-REE WIFI UPDATE & PERFECT GIFT CHOICE】With the fantastic AUTOVIN function, this nt614 scan tool can get your VIN and vehicle info rapidly. No need to spend much time in finding your VIN and input it one by one. Also, the lifetime f-ree wifi update is provided for more vehicle coverage, bug fixes, newly added parameters. SAVE AT LEAST 1000+ PER YEAR. And this automotive scanner is a best gift for your Dad, Husband, Boyfriend and Handy Men.

Last update on 2025-04-22 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.