| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 15V469

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components SUSPENSION

Potential Number of Units Affected 5,492

Incorrectly Heat Treated Rear Lower Control Arms

If the rear lower control arm fractures it may result in a change in ride height, loss of rear end stability, and reduced braking capabilities, increasing the risk of a crash.

Summary

Chrysler (FCA US LLC) is recalling certain model year 2015 Jeep

(FCA US LLC) is recalling certain model year 2015 Jeep Grand Cherokee and Dodge

Grand Cherokee and Dodge Durango vehicles manufactured June 12, 2015, to June 20, 2015. The affected vehicles may be equipped with rear lower control arms that may have been incorrectly heat treated. This may cause the rear lower control arm to fracture.

Durango vehicles manufactured June 12, 2015, to June 20, 2015. The affected vehicles may be equipped with rear lower control arms that may have been incorrectly heat treated. This may cause the rear lower control arm to fracture.

Remedy

Chrysler will notify owners, and dealers will inspect and if necessary replace the lower control arms, free of charge. The recall began July 29, 2015. Owners may contact Chrysler

will notify owners, and dealers will inspect and if necessary replace the lower control arms, free of charge. The recall began July 29, 2015. Owners may contact Chrysler customer service at 1-800-853-1403. Chrysler

customer service at 1-800-853-1403. Chrysler ’s number for this recall is R38. Note: This supersedes Recall No. 15V-407.

’s number for this recall is R38. Note: This supersedes Recall No. 15V-407.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

July 2015

Dealer Service Instructions for:

Safety Recall R38 Rear Suspension Lower Control Arms

NOTE: All of the involved vehicles in this recall were also involved in Safety Recall R33. Due to a change in the build date ranges of the lower control arms, a second inspection of most of the vehicles that were involved in Safety Recall R33 is required.

Models

NOTE: This recall applies only to the above vehicles built from June 12, 2015 through June 20, 2015 (MDH 061207 through 062015).

IMPORTANT: Many of the vehicles within the above build period have already been inspected or repaired and, therefore, have been excluded from this recall.

| IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory andshould perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. |

Subject

The rear suspension lower control arms on about 5,600 of the above vehicles may have been incorrectly heat treated during the manufacturing process. This could cause the rear suspension lower control arm to break. A broken rear suspension lower control arm(s), during certain driving conditions, could cause a loss of vehicle control and/or a crash without warning.

Repair

The build date code on both rear suspension lower control arms must be inspected. Lower control arms found within a certain build date range must be replaced.

Alternate Transportation

Dealers should attempt to minimize customer inconvenience by placing the owner in a loaner vehicle if inspection determines that the rear suspension control arm(s) replacement is required and the vehicle must be held overnight.

Parts Information

| Description | Part Number |

|---|---|

| Arm, Left Rear Lower Control | 52124811AG |

| Arm, Right Rear Lower Control | 52124810AG |

| Order one of each part below for each control arm being replaced: | |

| Bolt, Clevis | 06509622AA |

| Nut, Clevis | 06102252AA |

| Bolt, Ball Joint-to-Control Arm | 06506587AA |

| Nut, Hub | 06509298AA |

| Cap, Bolt Cover | 68077935AA |

| Order two of each part below for each control arm being replaced: | |

| Bolt, Lower Control Arm | 06104266AA |

| Nut, Lower Control Arm | 06104719AA |

| Order three of each part below for each control arm being replaced: | |

| Bolt, Tension/Toe/Camber Link | 06509461AA |

| Nut, Tension/Toe/Camber Link | 06104718AA |

Parts Return

No parts return required for this campaign.

Special Tools

The following special tools are required to perform this repair:

| wiTECH VCI Pod Kit |

| Laptop Computer |

| wiTECH Software |

Service Procedure

A. Rear Lower Control Arm Inspection

- Apply the “Parking” brake.

- Lift the vehicle on an appropriate hoist, if at the dealership, or crawl under the vehicle.

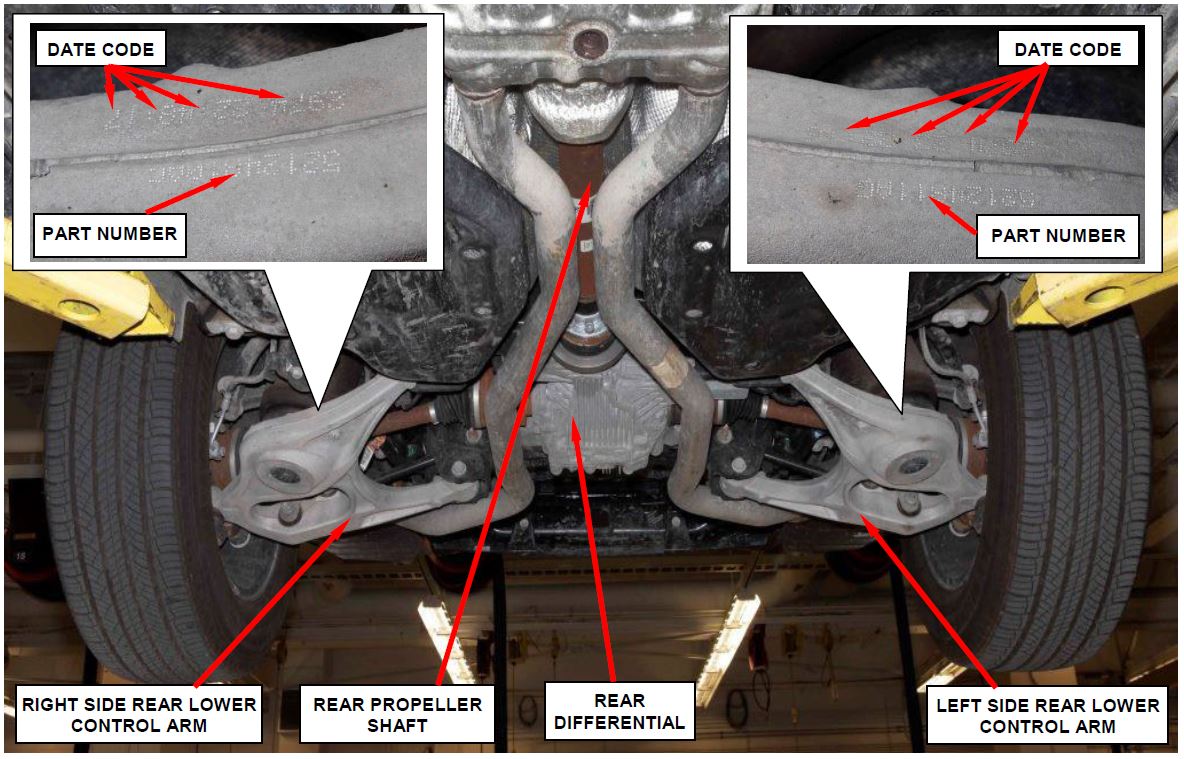

- Carefully clean the rear suspension lower control arms at the area where the build date code is located (Figure 1).

- Inspect the build date code on both rear suspension lower control arms:

NOTE: The build date code numbers are upside down on the control arm when installed on the vehicle.

- For the right rear lower control arm, if the build date code is on or between 1625 9:26:00 and 1635 08:10:00 replace the control arm. If off-site, first have vehicle towed to the dealership.

- For the left rear lower control arm, if the build date code is on or between 1625 9:54:00 and 1645 16:15:00 replace the control arm. If off-site, first have vehicle towed to the dealership.

- If the build date code is not legible, replace the lower control arm(s). If off-site, first have vehicle towed to the dealership.

If control arm replacement is required, for vehicles with air suspension continue with Section B. Depressurize Air Suspension. For vehicles without air suspension, continue with Section C. Replace rear suspension lower control arm.

Figure 1 – Date Code Location

B. Depressurize Air Suspension (WK Only)

- Connect the wiTECH scan tool to the vehicle.

- Start a wiTECH session.

- From the “Vehicle View” screen, select the “ASCM” icon.

- Select the “ Functions” tab.

- Select “Disable Level Control” from the list.

- Follow the screen prompts.

- Select “Spring Deflate to Reservoir” from the list.

- Follow the screen prompts.

- Repeat Steps 7 and 8 of this procedure to insure the air suspension is fully deflated.

- Continue with Section C. Replace Rear Suspension Lower Control Arms.

C. Replace Rear Suspension Lower Control Arm

- For WD models only, remove the spare tire.

- Release the park brake and lift the vehicle on the hoist.

- Remove the rear wheel(s).

- Bottom the caliper pistons into the caliper by prying the caliper over.

- Remove the caliper slide pin covers and slide pins.

CAUTION: Never allow the disc brake caliper to hang from the brake hose. Damage to the brake hose will result. Provide a suitable support to hang the caliper securely.

- Remove the disc brake caliper from the adapter and hang it from a suitable support.

- Remove and save the brake caliper adapter.

- Remove and save the brake rotor.

- For WD models only, remove and save the spare tire plastic heat shield.

- Use the following procedure to disconnect the park brake cable end from the park brake equalizer:

a. Compress the equalizer return spring.

b. Pull the left brake cable out and disconnect the right side park brake cable.

c. Pull the left park brake cable out and hold it in place with needle nose locking plier that have rubber hose on the jaws.

d. Disconnect the equalizer from the left cable.

- Disconnect the park brake cable from the frame anchor.

- For left control arm replacement, disconnect the ride height sensor link at the lower control arm.

- Disconnect the rear stabilizer bar link at the lower control arm.

- Remove the wheel speed sensor from the rear suspension knuckle.

- Remove and discard the original halfshaft hub nut.

- Disconnect the tension link from the rear suspension knuckle.

- Disconnect the camber link from the rear suspension knuckle.

- Disconnect the toe link from the rear suspension knuckle.

- Remove and save the rear suspension coil spring or suspension airbag (as equipped).

- Disconnect the lower shock absorber retaining bolt at the lower control arm.

- Disengage the halfshaft from the rear wheel hub.

CAUTION: Support the halfshaft, do not allow the halfshaft to hang.

- Pull the park brake cable out of the plastic routing clip.

- Remove and discard the lower ball joint nut.

- Separate the rear suspension knuckle from the lower control arm ball joint.

- Remove and save the rear suspension knuckle.

- Remove and discard the lower control arm forward pivot nut.

- Push the lower control arm pivot bolt forward.

- Using a cut off wheel, cut off the lower control arm pivot bolt head.

- Remove and discard the remaining lower control arm pivot bolt.

- Remove and discard the lower control arm rear pivot bolt nut.

- While holding the lower control arm, remove and discard the rear lower control arm pivot bolt and remove the original lower control arm from the vehicle.

- For left control arm replacement, transfer the load sensor bracket from the original lower control arm to the new lower control arm.

- Place the new lower control arm into position and install the lower control arm forward pivot bolt first.

- Install the lower control arm forward pivot bolt nut hand-tight.

NOTE: The front control arm to cradle bolt is installed from rear to front so that the nut is installed on the fuel tank side. This is the opposite of the manufacturing installation.

- Install the lower control arm rear pivot bolt and nut. Hand-tighten the nut only.

- Place the original rear suspension knuckle into position on the lower ball joint stud. Install the new ball joint nut and tighten to 129 ft. lbs. (175 N·m).

- Insert the halfshaft into the rear wheel hub.

- Route the park brake cable through the plastic routing clip.

- Insert a new tow link nut and bolt. Hand-tighten only.

- Insert a new camber link nut and bolt. Hand-tighten only.

- Insert a new tension link bolt and nut. Hand-tighten only.

- Install a new halfshaft retaining nut. Tighten the nut to 221 ft. lbs. (300 N·m).

- For left control arm replacement, connect the ride height sensor link to the lower control arm.

- Install the wheel speed sensor. Tighten the retaining bolt to 97 in. lbs. (11 N·m).

- Connect the park brake cable to the park brake equalizer.

- For WD models only, install the spare tire plastic heat shield.

- Install the brake rotor.

- Install the brake caliper adapter. Tighten the adapter bolts to 81 ft. lbs. (110 N·m).

- Install the brake caliper. Tighten the brake caliper slide pins to 20 ft. lbs. (28 N·m). Then install slide pin caps.

- Install the rear suspension coil spring or suspension airbag (as equipped).

CAUTION: Be sure the spring is “Keyed” correctly to the lower control arm.

- Place the shock absorber into position on the lower control arm and install a new nut and bolt. Tighten the nut to166 ft. lbs. (225 N·m).

- Connect the rear stabilizer bar link to the lower control arm. Install a new nut and tighten the nut to 75 ft. lbs. (102 N·m).

- Install the rear wheel(s).

- Lower the vehicle from the hoist.

- For WD models only, install the spare tire.

- For vehicles:

- with air suspension, continue with Section D. Pressurize Air Suspension.

- without air suspension, continue with Section E. Four Wheel Alignment.

D. Pressurize Air Suspension

- Connect the wiTECH scan tool.

- Start a wiTECH session.

- From the “Vehicle View” screen, select the “ASCM” icon.

- Select the “ Functions” tab.

- Select “Disable Level Control” from the list.

- Follow the screen prompts.

- From the “Misc. Functions” tab, select “Fill Spring from Reservoir”.

- Follow the screen prompts.

- Perform “Short Fill”.

- Inspect air spring for proper installation.

- Select “Complete Fill” from the list.

- Follow the screen prompts.

- Clear all Diagnostic Trouble Codes (DTC’s).

- Remove the wiTECH scan tool from the vehicle.

- Continue with Section E. Four Wheel Alignment.

E. Four Wheel Alignment

- Place the vehicle on the alignment rack.

- With the vehicle weight on the tires, tighten the rear lower control arm forward and rear pivot bolts/nuts to 89 ft. lbs. (120 N·m) and then an additional angle to 45 degrees.

- Install a new plastic bolt cap on the forward side of the forward lower control arm pivot bolt nut.

NOTE: The bolt cover cap was removed from the bolt head but fits on the nut after the bolt direction changed from the manufacturing direction.

- With the vehicle weight on the tires, tighten the rear suspension toe link nut and bolt to 75 ft. lbs. (102 N·m).

- With the vehicle weight on the tires, tighten the rear suspension camber link nut and bolt to 75 ft. lbs. (102 N·m).

- With the vehicle weight on the tires, tighten the rear suspension tension link nut and bolt to 75 ft. lbs. (102 N·m).

- For vehicles with air suspension, perform the following before aligning the vehicle:

a. Start the engine

b. Turn the radio on.

c. Select the “” Icon on the radio screen.

d. Select “Favorite Apps.” on the radio screen.

e. Select “Settings” on the radio screen.

f. Select “Suspension” on the radio screen.

g. Select “Wheel Alignment Mode” on the radio screen.

- Install wheel alignment equipment following the alignment machine instructions.

- Use the following procedure to adjust rear wheel camber:

a. Adjust the wheel camber position by loosening the camber link to cradle cam bolt/nut just enough to rotate the cam bolt. Turning the cam bolt moves the camber link in or out.

b. Tighten the camber link to cradle cam bolt/nut to 58 ft. lbs. (79 N·m).

c. Verify the specifications.

d. Continue with Step 10 of this procedure.

- Use the following procedure to adjust rear wheel toe:

a. Adjust the wheel toe position by loosening the toe link to cradle cam bolt/nut just enough to rotate the cam bolt. Turning the cam bolt moves the toe link in or out.

b. Tighten the toe link to cradle cam bolt/nut to 58 ft. lbs. (79 N·m).

c. Verify the specifications.

- Align front wheels as required.

- Remove the alignment equipment from the vehicle.

- Road test the vehicle.

- Return the vehicle to the customer.

NOTE: Specifications are in degrees.

| Front Alignment Specifications | ||||||

| Total Toe** | Caster | Cross Caster | Left

Camber | Right

Camber | Cross Camber | |

| Aero Suspension | 0.20° +/- 0.13° | 5.18° +/- 0.60° | 0.00° +/- 1.00° | -0.52° +/- 0.60° | -0.92° +/- 0.60° | 0.40° +/- 0.60° |

| Base Suspension (LHD) | 0.20° +/- 0.13° | 4.84° +/- 0.60° | 0.00° +/- 1.00° | -0.17° +/- 0.60° | -0.57° +/- 0.60° | 0.40° +/- 0.60° |

| Base Suspension (RHD) | 0.20° +/- 0.13° | 4.84° +/- 0.60° | 0.00° +/- 1.00° | -0.57° +/- 0.60° | -0.17° +/- 0.60° | -0.40° +/- 0.60° |

| Air Suspension (Aero Mode) (LHD) | 0.20° +/- 0.13° | 5.27° +/- 0.60° | 0.00° +/- 1.00° | -0.64° +/- 0.60° | -1.04° +/- 0.60° | 0.40° +/- 0.60° |

| Air Suspension (Aero Mode) (RHD) | 0.20° +/- 0.13° | 5.27° +/- 0.60° | 0.00° +/- 1.00° | -1.04° +/- 0.60° | -0.64° +/- 0.60° | -0.40° +/- 0.60° |

| SRT8 (with 3 season tires) | 0.20° +/- 0.13° | 5.21° +/- 0.55° | 0.00° +/- 0.55° | -1.61° +/- 0.55° | -1.61° +/- 0.55° | 0.00° +/- 0.55° |

| SRT8 (with 4 season tires) | 0.20° +/- 0.13° | 5.21° +/- 0.55° | 0.00° +/- 0.55° | -1.31° +/- 0.55° | -1.61° +/- 0.55° | 0.30° +/- 0.55° |

| Notes: | ||||||

| Positive toe (+) is toe-in and negative toe (−) is Toe-out. | ||||||

| ** TOTAL TOE is the sum of both the left and right wheel toe settings. TOTAL TOE should be equally split between each wheel on the same axle to ensure the steering wheel is centered after setting toe. | ||||||

| Rear Alignment Specifications | |||||

| LHD and RHD | Toe | Total Toe** | Thrust Angle | Camber | Cross Camber |

| Aero Suspension | 0.10° +/- 0.15° | 0.20° +/- 0.30° | 0.00° +/- 0.15° | -0.88 +/- 0.55 | 0.00° +/- 0.60° |

| Base Suspension | 0.10° +/- 0.15° | 0.20° +/- 0.35° | 0.00° +/- 0.15° | -0.54 +/- 0.55° | 0.00° +/- 0.60° |

| Air Suspension (Aero Mode) | 0.20° +/- 0.15° | 0.40° +/- 0.30° | 0.00° +/- 0.15° | -1.09° +/- 0.55° | 0.00° +/- 0.60° |

| SRT8 | 0.125° +/- 0.10° | 0.25° +/- 0.20° | 0.00° +/- 0.10° | -1.30° +/- 0.50° | 0.00° +/- 0.55° |

| Notes: | |||||

| Positive toe (+) is toe-in and negative toe (−) is Toe-out. | |||||

| ** TOTAL TOE is the sum of both the left and right wheel toe settings. TOTAL TOE should be equally split between each wheel on the same axle to ensure the steering wheel is centered after setting toe. | |||||

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims submitted will be used by FCA to record recall service completions and provide dealer payments.

Use the following labor operation numbers and time allowances:

| Labor Operation Number | Time Allowance | |

|---|---|---|

| All Models: Inspect right and left rear suspension lower control arm build date codes | 02-R3-81-81 | 0.2 hours |

| WK Models: Inspect right and left rear suspension lower control arm build date codes and replace one lower control arm (includes four wheel alignment) | 02-R3-81-82 | 3.7 hours |

| WK Models: Inspect right and left rear suspension lower control arm build date codes and replace both lower control arms (includes four wheel alignment) | 02-R3-81-83 | 5.1 hours |

| WD Models: Inspect right and left rear suspension lower control arm build date codes and replace one lower control arm (includes four wheel alignment) | 02-R3-81-84 | 4.0 hours |

| WD Models: Inspect right and left rear suspension lower control arm build date codes and replace both lower control arms (includes four wheel alignment) | 02-R3-81-85 | 5.4 hours |

| Optional Equipment | ||

| Air Suspension (WK models Only) | 02-R3-81-60 | 0.4 hours |

| Related Operation | ||

| Commute to the vehicle to perform an on-site rear lower control arm inspection | 02-R3-81-50 | Actual Time |

| Fuel Allowance | 95-14-01-54 | $15.00 |

Add the cost of the recall parts package plus applicable dealer allowance to your claim.

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Enclosed with each owner letter is an Owner Notification postcard to allow owners to update our records if applicable.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

REAR SUSPENSION LOWER

CONTROL ARMS

IMPORTANT SAFETY RECALL

R38

This notice applies to your vehicle (VIN: xxxxxxxxxxxxxxxxx).

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

Dear: (Name)

FCA has decided that a defect, which relates to motor vehicle safety, exists in certain 2015 model year Dodge Durango and Jeep

Durango and Jeep ® Grand Cherokee vehicles.

® Grand Cherokee vehicles.

| The problem is… | The rear suspension lower control arms on your vehicle may have been incorrectly heat treated during the manufacturing process. This could cause the rear suspension lower control arm to break. A broken rear suspension lower control arm(s), during certain driving conditions, could cause a loss of vehicle control and/or a crash without warning.

NOTE: Your vehicle may have been previously inspected in Safety Recall R33. Due to a change in the inspection date range, a second rear suspension lower control arm inspection is required. |

| What your dealer will do… | FCA will repair your vehicle free of charge. To do this, your dealer will inspect, and replace as required, the rear suspension lower control arms. The inspection will take about ½ hour to complete. If the control arm(s) require replacement up to an additional 6 hours will be required. However, additional time may also be necessary depending on service schedules. |

| What you must do to ensure your safety… | Simply contact your Chrysler , Jeep , Jeep , Dodge , Dodge or RAM or RAM dealer right away to schedule a service appointment. Please bring this letter with you to your dealer. dealer right away to schedule a service appointment. Please bring this letter with you to your dealer. |

| If you need help… | If you have questions or concerns which your dealer is unable to resolve, please contact the |

FCA Group Recall Assistance Center at either recalls.mopar.com or 1-800-853-1403.

Please help us update our records by filling out the attached prepaid postcard if any of the conditions listed on the card apply to you or your vehicle. If you have further questions go to recalls.mopar.com.

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online or you can mail your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement. Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you’ve had previous repairs and/or reimbursement you may still need to have the recall repair performed on your vehicle.

If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to safercar.gov.

We’re sorry for any inconvenience, but we are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Services / Field Operations

FCA US LLC

Note to lessors receiving this recall: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

Safety Recall R38

Rear Suspension Lower Control Arms

July 2015

Loading...

Loading...

Owner Notification Letter

Loading...

Loading...

Safety Recall R38

Rear Suspension Lower Control Arms

July 2015

Loading...

Loading...

Renotification Notice

January 29, 2016

Loading...

Loading...

Communications Cover Letter

August 5, 2015

Loading...

Loading...

Safety Recall R38 (STOP DRIVE) – Rear Suspension Lower Control Arms (Dealer Service Instructions)

07/23/2015

Loading...

Loading...

Chronology

July 21, 2015

Loading...

Loading...

Recall Acknowledgement

August 19, 2015

Loading...

Loading...

- BUFF OUT IMPERFECTIONS: Meguiar's Ultimate Compound removes scratches, swirls & oxidation for a clear, perfect finish

- SHOWROOM SHINE: Advanced car compound removes scratches, swirls, oxidation & water spots and restores color & clarity for a showroom shine in minutes

- CLEAR COAT SAFE: Auto compound safely removes scratches and other defects without hazing on clear coats & all gloss paints. Easy DIY fix by hand or da polisher

- LIKE-NEW SHINE: Meguiar's exclusive micro-abrasive technology quickly removes scratches & restores clarity and shine for a stunning, swirl-free finish.

- FAST & FLAWLESS: Meguiar's Ultimate Compound cuts fast, removes scratches and swirls without hazing, leaving a pro-detailer finish.

- 3-IN-ONE CERAMIC TECHNOLOGY: One 16 fl oz bottle of Nu Finish Once a Year Polish and Sealant, a car polish and paint sealant with 3-in-1 Ceramic Technology to repair, seal and repel

- REPAIRS SCRATCHES AND RENEWS SHINE: Long-lasting auto polish that helps repair fine swirls, scuffs and scratches while renewing the shine on paint and chrome, leaving a glossy, wet finish without any wax

- PREVENTS FUTURE SCRATCHES: Innovative Ceramic Technology forms an effective, durable protective barrier that helps prevent future scratches from forming and delivers extreme water beading for easier maintenance

- NO RUBBING OR BUFFING: Unique liquid polish that requires no rubbing or buffing and can even be applied in direct sunlight, unlike conventional car wax

- THE ONCE A YEAR CAR POLISH AND SEALANT: With just one application, you can polish and protect your car’s paint for an entire year* (*Based on U.S. average automatic car washes per year)

- The polish gives deep reflections & a hi-gloss paint finish

- Eliminates fine swirl marks

- Conditioning oils add depth of colour and maximum gloss prior to waxing, especially on dark coloured cars

- Quickly and gently removes fine swirls and towel marks for mirror-like reflections

- Safe and on all glossy paints, including clear coats.Pre-waxing glaze that prepares the surface for wax while offering deep reflections and high gloss

- CLEANER WAX: One-step liquid wax cleans your paint while you wax

- HIGH GLOSS SHINE: Rich conditioning oils polish and protect, leaving finish with a high gloss shine

- SAFE ON ALL GLOSSY FINISHES: Safely and effectively cleans surface contaminants and blemishes from all glossy paint finishes including clear coats and single-stage paint

- EASE OF USE: Easier to use than traditional carnauba wax

- VERSATILE APPLICATION: Can be applied by hand or Dual Action Polisher like Meguiar's MT300

- EXCEPTIONAL RESULTS: Advanced technology formula provides a deep gloss and rich, swirl-free results, ensuring the luxury your vehicle deserves. This mirror glaze goes above and beyond to produce a high gloss finish with no defects left behind.

- NO MORE SWIRLS: Meguiar's M20508 Mirror Glaze Ultra Finishing Polish permanently and efficiently removes swirls and light defects from all paint in favor of a deep gloss. This powerful car polish gets the job done and leaves a lasting finish.

- STUNNING SHINE: Ultra Finishing Polish produces deep reflections and high gloss without leaving a mess behind. Treat your ride to a stunning shine with a professional polish that achieves an impeccable shine and gloss.

- EASY-TO-USE: Whether working by rotary, DA polisher, or hand, this professional polishing compound goes on and wipes off easily for a quick and easy cleanup. This Finishing Polish is the perfect way to enhance and refine paint and increase gloss.

- MULTIPLE WAYS TO APPLY: Formulated for use by hand, DA polisher, or rotary buffer. It's the perfect product to follow a more aggressive compound like Ultra Cut Compound M105 and before applying paint protection, like Pro Hybrid Ceramic Sealant M27.

- EASY SCRATCH and SWIRL REPAIR - If your car has light scratches, swirls, or other marks - you can easily fix that with our Scratch & Swirl Remover Kit! Using the included buffer pad, our specially formulated compound will allow you to easily remove and "erase" years of wear and tear from your vehicles paint and overall appearance!

- ULTIMATE PAINT REPAIR- Not only will this remove swirls and scratches, it will restore the gloss and shine of your paint and bring it back to its original brilliance! The special rubbing compound will remove water spots, oxidation and other contaminants from your paint!

- PREMIUM CHEMICALS - We formulate all our products to ensure they are the best! Professional grade, but easy enough for anyone to use! We use only the absolute best chemicals and ensure there are no unnecessary color dyes or scents!

- ADVANCED SOLUTION FOR ALL PAINT TYPES - Car paint scratch repair is safe to use on all paints and colors. You can safely use it on any clearcoat, single stage, or multi stage paint!

- REVOLUTIONARY PRODUCT - This scratch remover for vehicles provides an effortless and secure way to remove scratches.

- Advanced Formula 3-in-1. Our fortify quick coat is your all-in-one ceramic coating hydrophobic spray. Shine Armor Fortify Quick Coat ceramic car wax provides a waterless wash, coat, and shine, all-in-one convenient product.

- No Streaking, Smearing Or Scratching. Shine Armor Fortify Quick Coat premium formula ceramic car coating is a gentle and effective car polish for any vehicle! Get a clean, shiny finish without hurting your car's paint.

- Cuts Dirt, Grime & Grease. Our Quick Coat ceramic wax car sealant eliminates dirt, grime & grease instantly! Our signature 3-in-1 formula gives you a waterless car wash, coat and shine for a clean, showcase look.

- Safe For All Surfaces. Use this car wax spray-on automobiles, boats, motorbikes, RVs, four-wheelers and more! This spray wax is the perfect blend of surfactants and SiO2 ceramic-coating science.

- Superior Products. This means superior shine for your cars! Our ceramic quick coat also works as a sealer to give your vehicle a clear shield of protection while also providing a beautiful gloss. Which makes our ceramic spray the perfect Christmas Gift for the gearhead in your life!

- Can be applied to wet or dry paint

- Provides a deep, dark gloss and shine while adding protection

- Ease and convenience of a spray-on, wipe-off product saves on time

- Can be applied in full sun and won't whiten plastic trim

- Offers protection against the sun

- OUTSTANDING POLISH: Top-performing glaze among hand-applied polishes, glazes, waxes and sealants

- SHOW CAR SHINE: Restores a dazzling, deep wet shine

- SAFE FOR ALL FINISHES: Body shop safe and effective on all glossy paint finishes including clear coats

- DRIES CLEAR: Does not dry white, leaving a clear glossy shine

- CHOOSE HOW YOU USE: Formulated for use by hand, DA polisher or rotary buffer

- One 16 oz bottle of Nu Finish The Once A Year Car Polish

- Automotive polish that is made up of a series of zinc cross-linking polymer emulsions that help it last longer than any other polish on the market

- Nu Finish car polish can be applied anywhere, even in direct sunlight

- Also an ideal boat polish, motorcycle polish and chrome polish

- The only auto polish tough enough to be called "The Once A Year Car Polish”

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.