| “This site contains affiliate links for which OEMDTC may be compensated” |

May 9, 2019 NHTSA CAMPAIGN NUMBER: 19V348000

Engine Stall or Loss of Power Steering Assist

A loss of power steering assist or a stall can increase the risk of crash.

NHTSA Campaign Number: 19V348

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components ELECTRICAL SYSTEM

Potential Number of Units Affected 198,731

Summary

Chrysler (FCA US LLC) is recalling certain 2017-2019 Pacifica vehicles equipped with engine stop/start systems. A loose battery ground connection may result in an intermittent loss of power steering assist and/or a stall.

(FCA US LLC) is recalling certain 2017-2019 Pacifica vehicles equipped with engine stop/start systems. A loose battery ground connection may result in an intermittent loss of power steering assist and/or a stall.

Remedy

Chrysler will notify owners, and dealers will inspect the battery ground surfaces, clean the contact surfaces as needed, and properly reassemble the ground connection, free of charge. The recall began May 24, 2019. Owners may contact Chrysler

will notify owners, and dealers will inspect the battery ground surfaces, clean the contact surfaces as needed, and properly reassemble the ground connection, free of charge. The recall began May 24, 2019. Owners may contact Chrysler customer service at 1-800-853-1403. FCA US’ number for this recall is V53.

customer service at 1-800-853-1403. FCA US’ number for this recall is V53.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

May 2019

Dealer Service Instructions for:

Safety Recall V53 / NHTSA 19V-348 Power Steering Assist

Remedy Available

| 2017-2019 | (RU) | Chrysler Pacifica Pacifica |

NOTE: Some vehicles above may have been identified as not involved in this recall and therefore have been excluded from this recall.

IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process.

Subject

The battery ground on about 198,800 of the above vehicles may have been built with a sealer that is used during the wire harness manufacturing process may accumulate on the wire harness tab which may cause a loss of clamp load in the battery ground joint over time. A loose battery ground joint may cause an intermittent battery ground connection possibly resulting in an intermittent loss of power steering assist with inconsistent driver steering effort and/or a loss of motive power. An intermittent loss of power steering assist may result in an inconsistent driver steering effort, especially during lower speed maneuvers. A loss of motive power could also occur. Either of these conditions may increase the risk of a vehicle crash without prior warning.

Repair

Disassemble and inspect the suspect ground surfaces, clean the contact surfaces as needed, and reassemble the ground joint to the specified torque.

Parts Information

No parts are required to perform this service procedure.

Parts Return

No parts return required for this campaign.

Special Tools

No special tools are required to perform this service procedure.

Service Procedure

- Open the hood.

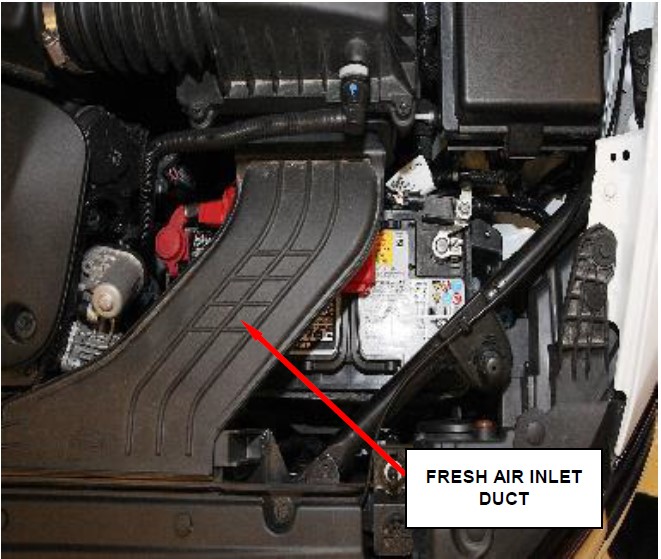

- Remove the fresh air inlet duct (Figure 1).

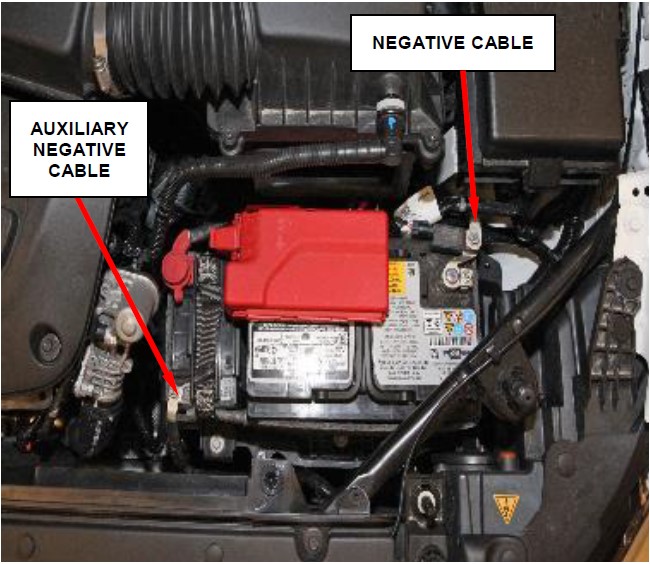

- Disconnect the negative battery cables (Figure 2).

Figure 1 – Fresh Air Inlet Duct

- Raise and support the vehicle.

Figure 2 – Negative Battery Cables

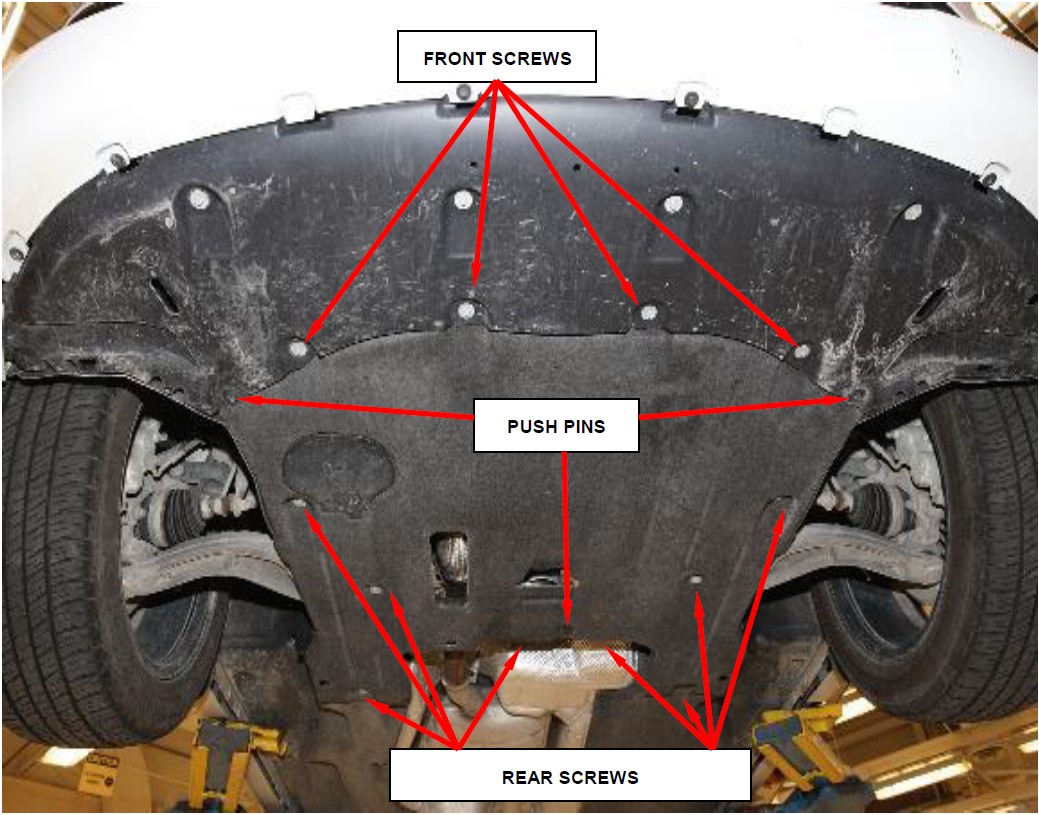

- Remove the four screws attaching the wheelhouse splash shields to the front belly pan.

- Remove the four front screws (Figure 3).

- Remove the three push pins (Figure 3).

- Remove the eight rear screws (Figure 3).

Figure 3 – Front Belly Pan

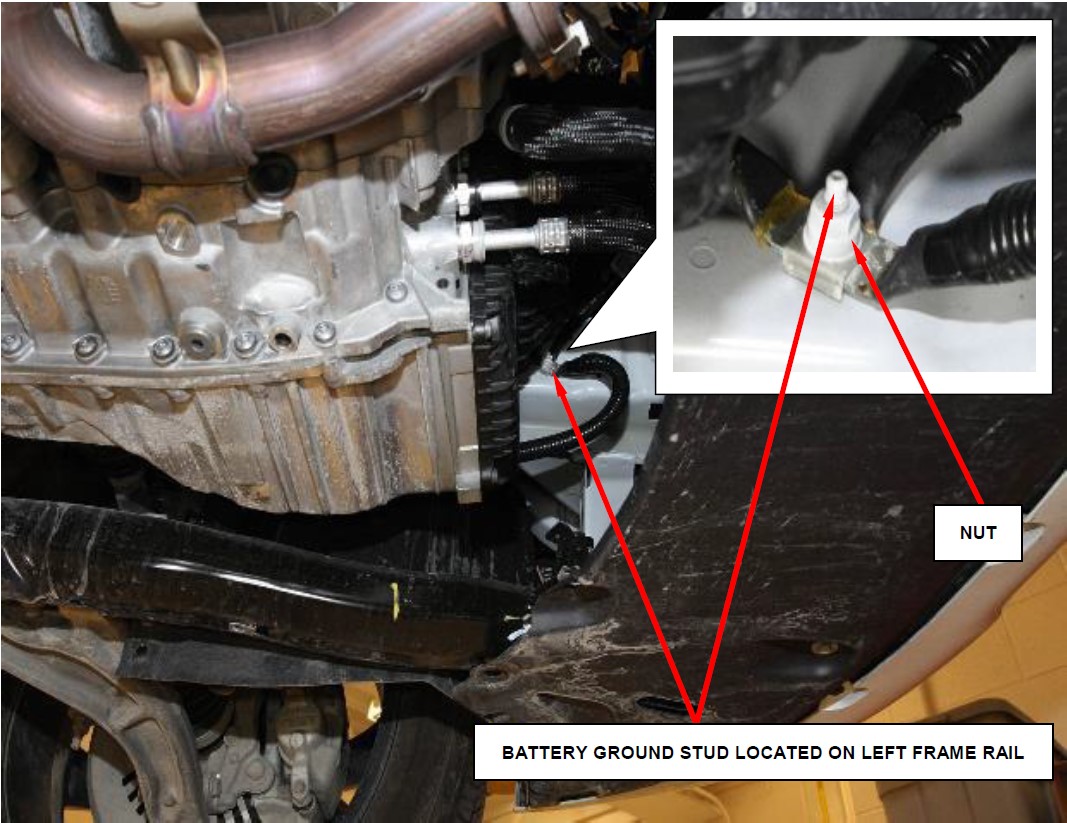

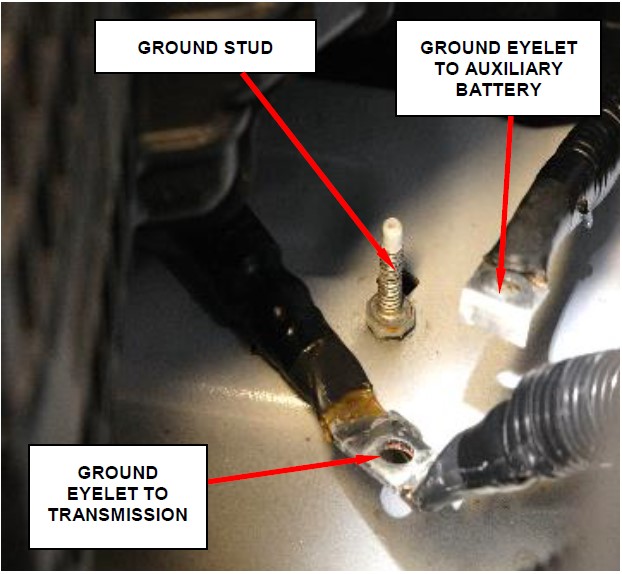

- Locate the battery ground stud located on the left frame rail toward the front of the vehicle (Figure 4).

- Remove the ground nut from the ground stud (Figure 4).

Figure 4 – Battery Ground Stud Location

- Remove the two ground eyelets from the ground stud (Figure 5).

Figure 5 – Ground Eyelets

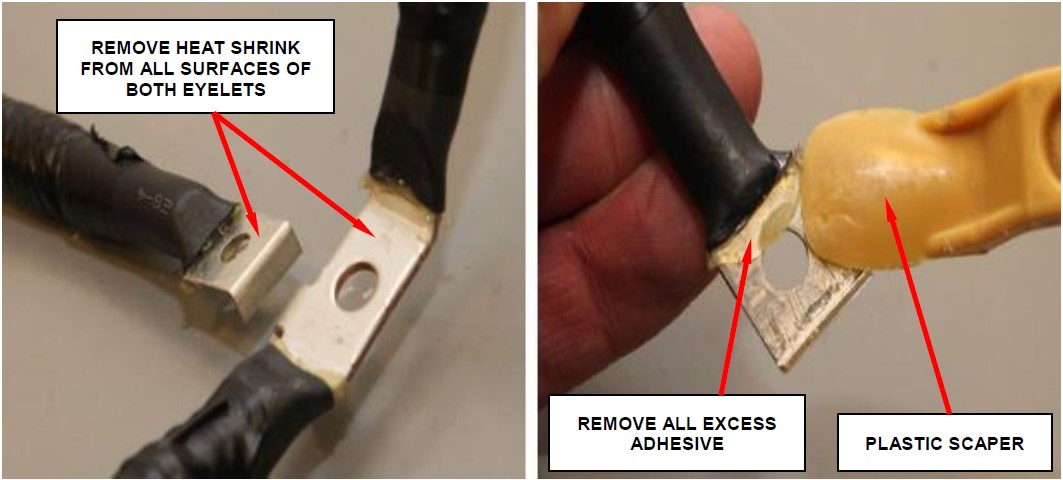

CAUTION: To avoid terminal plating damage, do not use metal scrapers to remove heat shrink adhesive from terminals.

- Using a plastic scraper, remove excess heat shrink adhesive from all ground terminal connection surfaces (Figure 6).

Figure 6 – Ground Terminals

(Ground Cables Removed from Vehicle for Photographic Purposes Only)

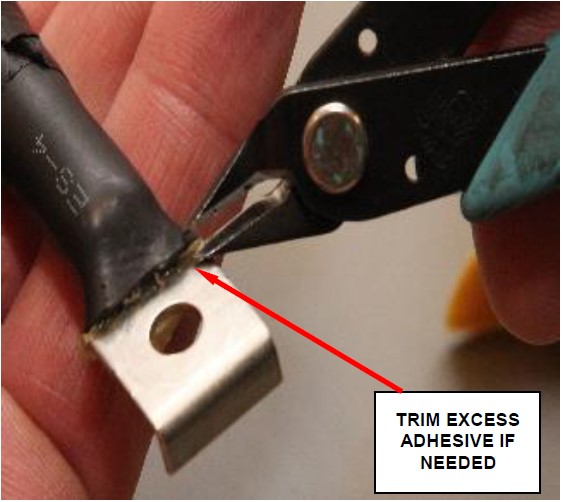

- If needed, trim excess heat shrink adhesive as close as possible to the heat shrink tubing (Figure 7).

Figure 7 – Trim Excess Adhesive

- Using a plastic scraper, remove excess heat shrink adhesive from the ground stud and nut (Figure 5).

- Clean all ground terminal, ground stud and ground nut surfaces with Electrical Contact Cleaner or equivalent.

- Position the two ground eyelets on the ground stud.

- Install the ground nut to the ground stud and tighten to 9 N·m (80 in. lbs.).

- Position the front belly pan to the front fascia.

- Install the four front screws and tighten securely.

- Install the three push pins.

- Install the eight rear screws and tighten securely.

- Install the four screws attaching the wheelhouse splash shields to the front belly pan and tighten securely.

- Lower the vehicle.

- Connect both negative battery cables.

- Install the fresh air inlet duct.

- Close the hood and return the vehicle to the customer.

SEOCONTENT-START

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments.

Use the following labor operation number and time allowance:

| Labor Operation Number | Time Allowance | |

|---|---|---|

| Repair Auxiliary Battery Ground Cable Connection | 08-V5-31-82 | 0.5 hours |

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

This notice applies to your vehicle,

[Model Year and Model] VIN XXXXXXXXXXXXXXXXX V53/NHTSA 19V-348

LOGO

VEHICLE PICTURE

YOUR SCHEDULING OPTIONS

- RECOMMENDED OPTION Call your authorized Chrysler

/ Dodge

/ Dodge / Jeep

/ Jeep ® / RAM

® / RAM Dealership

Dealership - Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can confirm part availability and help schedule an appointment

- Visit mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App.

QR Code

Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above.

DEALERSHIP INSTRUCTIONS

Please reference Safety Recall V53.

IMPORTANT SAFETY RECALL

Power Steering Assist

Dear [Name],

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

FCA has decided that a defect, which relates to motor vehicle safety, exists in certain [2017-2019 (RU) Chrysler Pacifica] vehicles.

It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers.

WHY DOES MY VEHICLE NEED REPAIRS?

The battery ground on your vehicle [1] may have been built with a sealer that is used during the wire harness manufacturing process may accumulate on the wire harness tab which may cause a loss of clamp load in the battery ground joint over time. A loose battery ground joint may cause an intermittent battery ground connection possibly resulting in an intermittent loss of power steering assist with inconsistent driver steering effort and/or a loss of motive power. An intermittent loss of power steering assist may result in an inconsistent driver steering effort, especially during lower speed maneuvers. A loss of motive power could also occur. Either of these conditions may increase the risk of a vehicle crash without prior warning.

HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE?

FCA will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will disassemble and inspect the suspect ground surfaces, clean the contact surfaces as needed, and reassemble the ground joint to the specified torque. The estimated repair time is one hour. In addition, your dealer will require your vehicle for proper check-in, preparation, and checkout during your visit, which require more time. Your time is important to us, so we recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership.

TO SCHEDULE YOUR FREE REPAIR,

CALL YOUR CHRYSLER, DODGE, JEEP OR RAM DEALER TODAY

WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED?

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed.

We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Assistance/Field Operations

FCA US LLC

Mr. Mrs. Customer

1234 Main Street

Hometown, MI 48371

[1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information.

[2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-4249153), or go to safercar.gov.

[3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement.

Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

SEOCONTENT-END

3 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

CHRYSLER | PACIFICA | 2017-2019 |

9 Associated Documents

ISSUED Owner Notification Letter(Part 577)

RCONL-19V348-1378.pdf 517.279KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – 05/10/2019 New Safety Recall Advanced Communication – V53

Loading...

Loading...

Recall Acknowledgement

RCAK-19V348-5993.pdf 245.201KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V348-8890.pdf 578.885KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-19V348-4704.PDF 214.204KB

Loading...

Loading...

Recall Quarterly Report #2, 2019-3

RCLQRT-19V348-6372.PDF 211.264KB

Loading...

Loading...

Recall Quarterly Report #3, 2019-4

RCLQRT-19V348-9098.PDF 211.359KB

Loading...

Loading...

Recall Quarterly Report #1, 2019-2

RCLQRT-19V348-5410.PDF 211.156KB

Loading...

Loading...

ISSUED Renotification Notice

RCRN-19V348-9961.pdf 136.474KB

Loading...

Loading...

Latest Recalls Documents

- WD-40 Specialist Contact Cleaner is ideal for removing oil, dirt, flux residue, and condensation from sensitive electrical equipment. This quick drying, residue-free formula is safe on metal and plastic

- Cleans sensitive electric equipment. Quick drying. Safe to use on most plastics 1, rubbers and metals. 1 Test on plastic before using, and avoid adhesives, device screens, and keyboards

- WD-40 Specialist offers easy solutions for specific problems. WD-40 Specialist line is designed with industrial strength quality for your tough jobs

- Blast away oil, dirt, flux residue and condensation from sensitive electronics and electrical equipment with pinpoint precision. It's ideal for use on printed circuit boards, controls, switches, precision instruments and electric panels

- WD-40 Brand believes in creating high-quality products that will not fail in extreme conditions. Professionals rely on WD-40 Specialist to get the job done right

- Not only does CLEAR CARE Solution clean your contact lenses with the bubbling power of hydrogen peroxide, it also surrounds your lenses with long-lasting moisture

- Patented HydraGlydeMoisture Matrix wraps your soft lenses in long-lasting moisture for a fresh lens feeling Triple Action Cleaning loosens dirt, deep cleans and removes protein

- Exclusive lens case features a platinum disc which activates our gentle, bubbling action and neutralizes our hydrogen peroxide into a gentle saline solution

- Never put CLEAR CARE Solution directly in or around your eyes Follow instructions completely and do not skip any steps

- Safe for all Soft and Rigid Gas Permeable Contact Lenses

- QD ELECTRONICS CLEANER: A precise cleaner made from petroleum distillate and alcohol that is fast evaporating and leaves no residue.

- FORMULA: With quick-drying, plastic safe, residue-free features, this cleaner is ideal for even the most sensitive electronics and will help to prevent contact failure.

- APPLICATIONS: QD Electronic Cleaner is ideal for use on computer components, circuit breakers, circuits, coin mechanisms, contacts, flux removal, sockets, lighting, plastics, nylon, plugs, relay switches, PVC, and more!

- PRODUCT SPECIFICATIONS: QD Electronic Cleaner is available in a 11 wt. oz. aerosol can.

- CRC INDUSTRIES: A market leader that offers impeccably designed chemical solutions to maintain, protect and repair different marine, heavy-duty motor vehicles, industrial-grade engines, household tools, and electrical equipment.

- Step 1 in the Boston ADVANCE Formula Care System

- Boston is the #1 eye doctor recommended brand of rigid gas permeable (RGP) contact lens solutions

- Rigid Gas Permeable contact lens solution from the eye care experts at Bausch + Lomb

- Contact lens solution removes debris and deposits from lenses

- Visibly tinted contact solution for faster rinsing

- Cleans, protects, lubricates, and improves conductivity

- Reduces intermittent connections, arcing, and RFI as well as wear and abrasion

- Safe for use on all metal connectors and contacts and will not harm plastics

- Dispensing Type: Spray

- Volume: 5 oz

- Package Dimensions :21.082 Cm L X 21.844 Cm W X 28.956 Cm H

- Product Type:Auto Accessory

- Item Package Weight:5.148 Kilograms

- Fit Type: Universal

- CRC INDUSTRIES: A market leader that offers impeccably designed chemical solutions to maintain, protect and repair different marine, heavy-duty motor vehicles, industrial-grade engines, household tools and electrical equipment

- QD Contact Cleaner: Helps to effectively eliminate dust, light oil, grease, and dirt from sensitive electronics and electrical equipment. This cleaner evaporates quickly, leaving no residue behind, and is safe to use on all plastics

- FORMULA: QD Contact Cleaner evaporates quickly, leaving no residue behind and is safe to use on all plastics. Use where lower flashpoint cleaners are acceptable

- APPLICATIONS: This liquid contact cleaner is ideal for use on telephones, PCs, relays, edge connectors, tape heads, busbars, circuits, contacts, printed circuit boards, switches and breakers

- PRODUCT SPECIFICATIONS: QD Contact Cleaner is available in an 11 wt. oz. aerosol can. This product is NSF K2 Registered

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.