| “This site contains affiliate links for which OEMDTC may be compensated” |

March 26, 2020 NHTSA CAMPAIGN NUMBER: 20V183000

Front Differential Pinion Gears May Wear

A sudden loss of power while driving or loss of the transmission PARK function can increase the risk of a crash.

NHTSA Campaign Number: 20V183

Manufacturer Chrysler (FCA US LLC)

(FCA US LLC)

Components POWER TRAIN

Potential Number of Units Affected 515

Summary

Chrysler (FCA US LLC) is recalling certain 2019 Jeep

(FCA US LLC) is recalling certain 2019 Jeep Grand Cherokee and Dodge

Grand Cherokee and Dodge Durango vehicles. The front differential may have been assembled with pinion gears that are insufficiently hardened, which can lead to the gear teeth wearing down. If both pinion gears have their teeth sufficiently worn off, torque power can not be transferred from the front wheels to the driveline, resulting in loss of power while driving and loss of the PARK function when stationary.

Durango vehicles. The front differential may have been assembled with pinion gears that are insufficiently hardened, which can lead to the gear teeth wearing down. If both pinion gears have their teeth sufficiently worn off, torque power can not be transferred from the front wheels to the driveline, resulting in loss of power while driving and loss of the PARK function when stationary.

Remedy

Chrysler will notify owners, and dealers will replace the front differential, free of charge. The recall began May 21, 2020. Owners may contact Chrysler

will notify owners, and dealers will replace the front differential, free of charge. The recall began May 21, 2020. Owners may contact Chrysler customer service at 1-800-853-1403. Chrysler

customer service at 1-800-853-1403. Chrysler ’s number for this recall is W22.

’s number for this recall is W22.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

03/27/2020

New Safety Recall Advanced Communication – W22

FCA US LLC (FCA US) has announced a safety recall on certain 2019 Model Year (WK) Jeep ® Grand Cherokee and 2019 Model Year (WD) Dodge

® Grand Cherokee and 2019 Model Year (WD) Dodge Durango vehicles equipped with a 3.6L engine and four-wheel drive Single Speed Transfer Case (Sales Code DHY).

Durango vehicles equipped with a 3.6L engine and four-wheel drive Single Speed Transfer Case (Sales Code DHY).

REASON FOR THIS SAFETY RECALL

Some of the above vehicles may have been built with a front differential that was assembled with pinion gears that are not hardened. This may result in the teeth of the gears wearing off, which can cause a loss of engagement between the pinion gears and the side gears. If both pinion gears have their teeth sufficiently worn off, torque cannot be transferred between the front wheels and the driveline. Because the single speed transfer case differential is open, the wheels rotate freely which results in a loss of motive power while the vehicle is in motion and a loss of the PARK function while stationary. In some circumstances, prior to a loss of motive power and/or inadvertent vehicle movement, the operator may notice a gear whine or a grinding noise. A loss of motive power or a loss of PARK function can cause a vehicle crash without prior warning and/or injury to others outside the vehicle.

SERVICE ACTION

FCA US will conduct a voluntary safety recall to replace the front differentials on affected vehicles. The remedy for this condition is not currently available. Dealers will be notified of the launch of this safety recall by way of established communication methods. This recall is estimated to launch in 2nd Quarter of 2020.

We ask that you please take the time to ensure that your personnel are aware of this communication and are prepared to execute a customer friendly process for inquiries regarding involved vehicles.

Customer Services Field Operations

FCA US LLC

04/02/2020

New Safety Recall Advanced Communication – W22

FCA US LLC (FCA US) has announced a safety recall on certain 2019 Model Year (WK) Jeep ® Grand Cherokee and 2019 Model Year (WD) Dodge

® Grand Cherokee and 2019 Model Year (WD) Dodge Durango vehicles equipped with a 3.6L engine and four-wheel drive Single Speed Transfer Case (Sales Code DHY).

Durango vehicles equipped with a 3.6L engine and four-wheel drive Single Speed Transfer Case (Sales Code DHY).

VINs identified as being involved in this campaign are currently live and searchable. Stop sale is in effect for the above-identified vehicles.

Vehicles impacted by a stop sale are eligible for reimbursement allowance through the Recall Floorplan Reimbursement Policy (RFPRP), which can be requested upon recall claim submission.

IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Violation of this requirement by a dealer could result in a civil penalty of up to $21,000 per vehicle. Involved vehicles can be determined by using the VIP inquiry process.

REASON FOR THIS SAFETY RECALL

Some of the above vehicles may have been built with a front differential that was assembled with pinion gears that are not hardened. This may result in the teeth of the gears wearing off, which can cause a loss of engagement between the pinion gears and the side gears. If both pinion gears have their teeth sufficiently worn off, torque cannot be transferred between the front wheels and the driveline. Because the single speed transfer case differential is open, the wheels rotate freely which results in a loss of motive power while the vehicle is in motion and a loss of the PARK function while stationary. In some circumstances, prior to a loss of motive power and/or inadvertent vehicle movement, the operator may notice a gear whine or a grinding noise. A loss of motive power or a loss of PARK function can cause a vehicle crash without prior warning and/or injury to others outside the vehicle.

SERVICE ACTION

FCA US will conduct a voluntary safety recall to replace the front differentials on affected vehicles. The remedy for this condition is not currently available. Dealers will be notified of the launch of this safety recall by way of established communication methods. This recall is estimated to launch in 2nd Quarter of 2020.

We ask that you please take the time to ensure that your personnel are aware of this communication and are prepared to execute a customer friendly process for inquiries regarding involved vehicles.

Customer Services Field Operations

FCA US LLC

May 2020

Dealer Service Instructions for:

Safety Recall W22 / NHTSA 20V-183 Front Axle Differential

Remedy Available

NOTE: This recall applies only to the above vehicles equipped with a 3.6L engine and four-wheel drive Single Speed Transfer Case (sales code DHY).

NOTE: Some vehicles above may have been identified as not involved in this recall and therefore have been excluded from this recall.

| IMPORTANT: Some of the involved vehicles may be in dealer new vehicle inventory. Federal law requires you to complete this recall service on these vehicles before retail delivery. Dealers should also consider this requirement to apply to used vehicle inventory and should perform this recall on vehicles in for service. Involved vehicles can be determined by using the VIP inquiry process. |

Subject

The front axle differential on about 560 of the above vehicles may have been assembled with pinion gears that are not hardened. This may result in the teeth of the gears wearing off, which can cause a loss of engagement between the pinion gears and the side gears. If both pinion gears have their teeth sufficiently worn off, torque cannot be transferred between the front wheels and the driveline. Because the single speed transfer case differential is open, the wheels rotate freely which results in a loss of motive power while the vehicle is in motion and a loss of the PARK function while stationary. In some circumstances, prior to a loss of motive power and/or inadvertent vehicle movement, the operator may notice a gear whine or a grinding noise. A loss of motive power or a loss of PARK function can cause a vehicle crash without prior warning and/or injury to others outside the vehicle.

Repair

Replace the front axle differential assembly.

Alternate Transportation

Dealers should attempt to minimize customer inconvenience by placing the owner in a loaner vehicle if the vehicle must be held overnight.

Parts Information

| Description | Part Number |

| Differential, Front Axle | CSAKW221AA |

| Each package contains the following components: | |

| Description | Quantity |

| Front Axle Differential | 1 |

| Description | Part Number |

| Fasteners Kit | CSAKW222AA |

| Each package contains the following components: | |

| Description | Quantity |

| Bolt, M10 Front axle differential to cradle | 2 |

| Nut, M10 Front axle differential to cradle | 1 |

| Bolt and Washer M12 Front axle differential to cradle | 1 |

| Nut, Half Shaft to hub and bearing | 2 |

| Nut, M14 – Not required for this campaign: DISCARD | 2 |

| Nut and Washer, M14 with Nylon Insert, Tie Rod End | 2 |

| Bolt, Front Prop to Pinion Flange | 3 |

| Washer, Halfshaft to hub and bearing | 2 |

| Nut, M18 strut clevis bracket to lower control arm | 2 |

| Bolt, M18 strut clevis bracket to lower control arm | 2 |

| Quantity | Description | Part Number |

| 2 | Nut and Washer, M14 with Nylon Insert, Upper Ball Joint (MOQ 2) | 06511398AA |

Parts Return

No parts return required for this campaign.

Render the recalled front axle differential unusable and discard.

Special Tools

The following special tools are required to perform this repair:

| Puller, Tie Rod |

| Press, Ball Joint |

| Protector, Half Shaft, Drive |

Service Procedure

A. Front Axle Differential Removal

- Disconnect the negative battery cables.

NOTE: All of the following front halfshaft removal steps must be performed to both the right and left sides of the vehicle.

- Position the vehicle on an appropriate lift, then raise and support the vehicle at a suitable height for wheel removal.

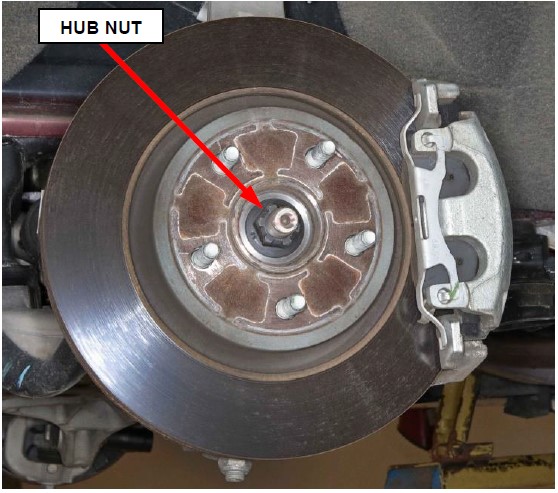

- Remove the hub nut from the halfshaft and discard. The used hub nut is not reusable (Figure 1).

Figure 1 – Front Hub Nut

NOTE: Always install a new hub nut. The original hub nut is one-time use only and should be discarded when removed.

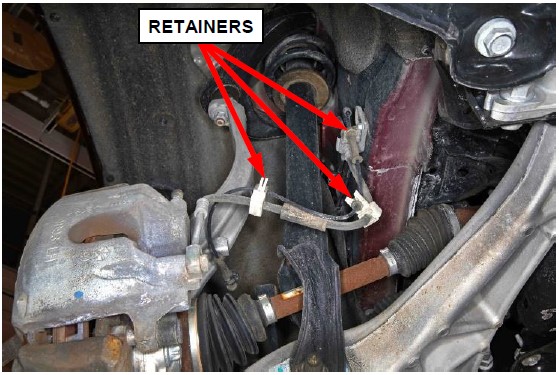

- Release the wheel speed sensor wire harness from the retainers along the brake hose (Figure 2).

Figure 2 – Wheel Speed Sensor Wire Harness Retainers

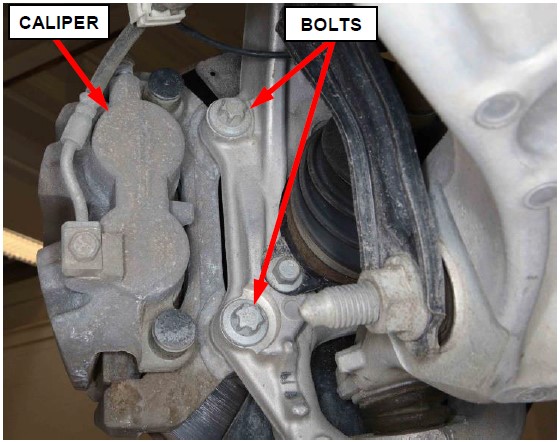

- Remove and SAVE the bolts (1) securing the brake caliper adaptor bracket to the steering knuckle (Figure 3).

Figure 3 – Brake Caliper Adaptor Bolts

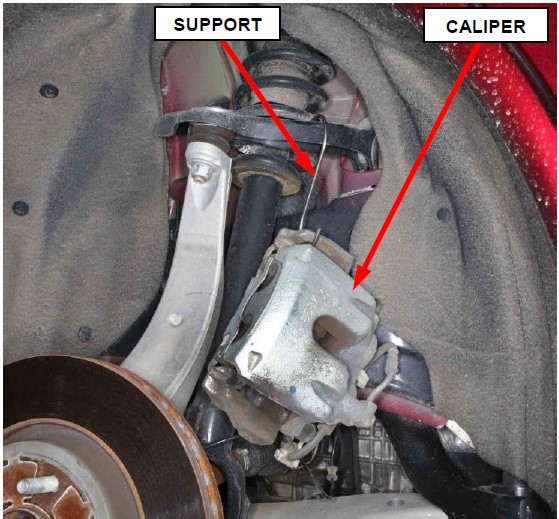

- Remove and support the brake caliper and bracket assemblies. Do NOT allow the brake caliper to hang by the brake hose (Figure 4).

Figure 4 – Support Brake Caliper

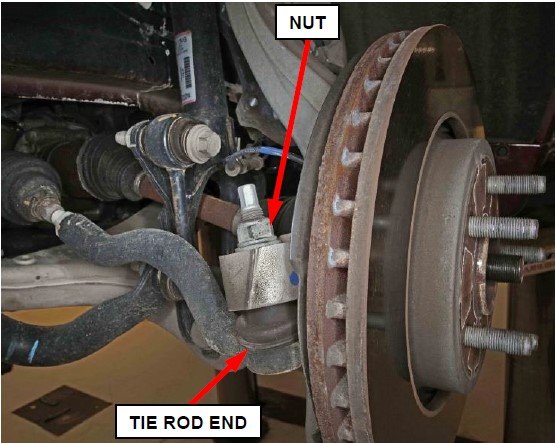

- Remove and DISCARD the tie rod nuts (1) (Figure 5).

Figure 5 – Outer Tie Rod End Nut

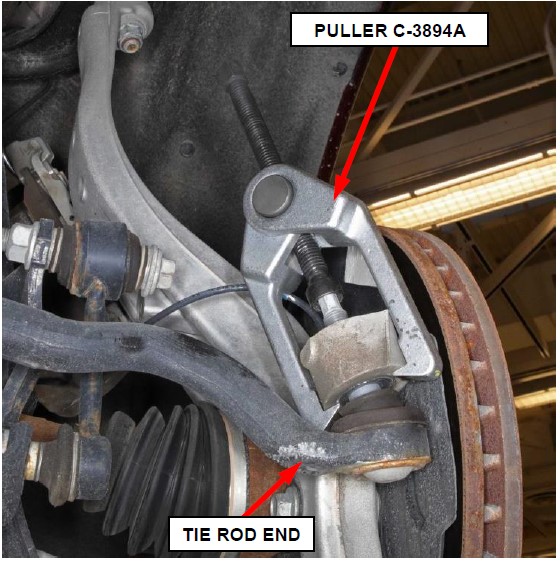

Figure 6 – Separate Outer Tie Rod End

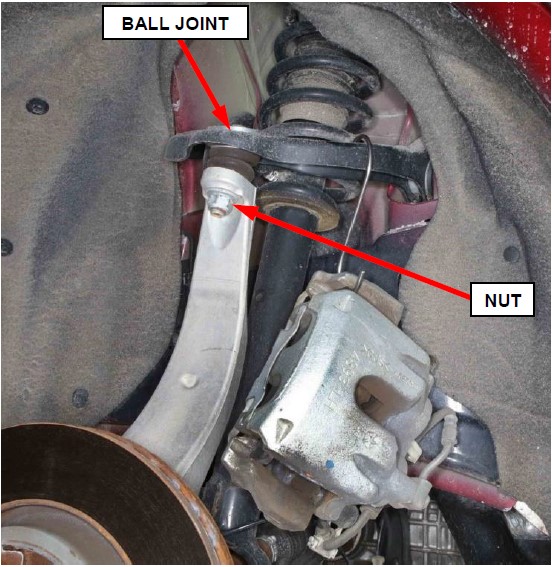

- Remove and DISCARD the upper ball joint nuts (Figure 7).

Figure 7 – Upper Ball Joint Nut

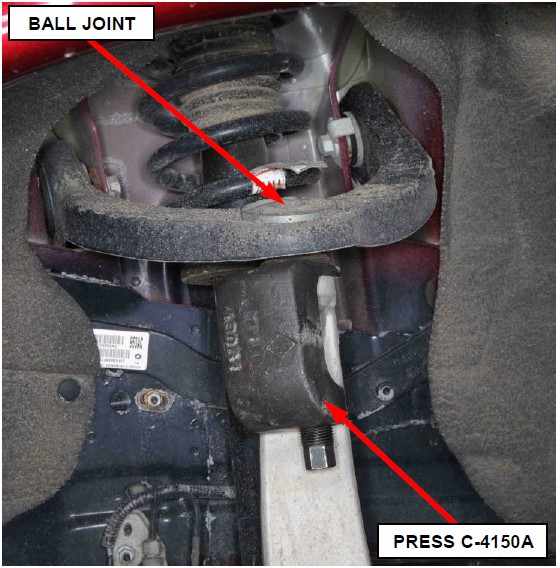

- Using Ball Joint Press C-4150A, separate the ball joints from the steering knuckles (Figure 8).

Figure 8 – Separate Upper Ball Joint

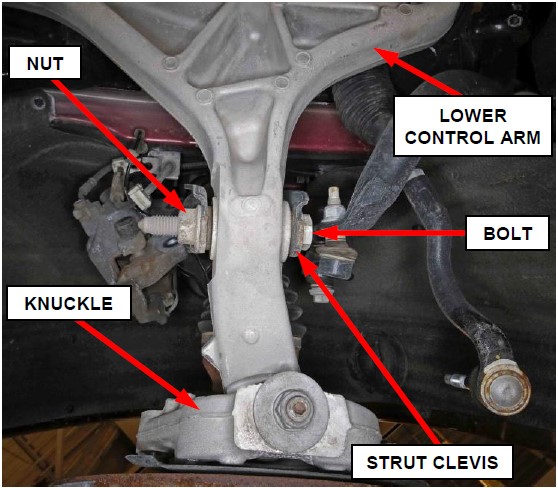

- Remove and DISCARD the front strut clevis bolt and nut (Figure 9).

Figure 9 – Front Strut Clevis Bolt and Nut

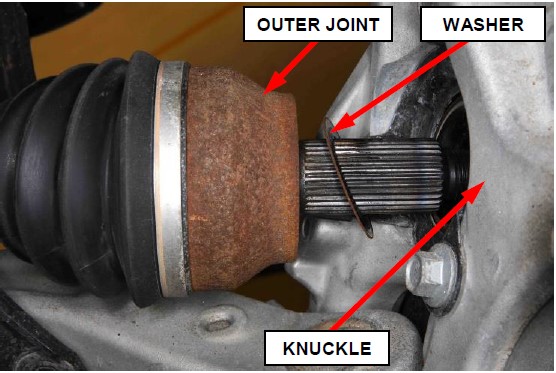

- While positioning the steering knuckle down and away, separate the outer half shaft joint from the hub (Figure 10).

- Remove and DISCARD the washer from between the outer half shaft joint and hub (Figure 10).

Figure 10 – Outer Half Shaft Joint

- Raise the vehicle.

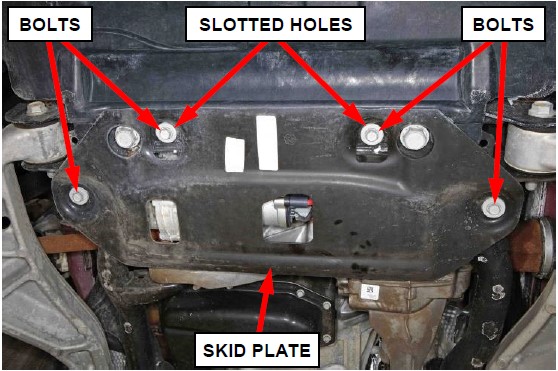

- If equipped: Remove and SAVE the bolts and skid plate from the front suspension cradle (Figure 11).

Figure 11 – Suspension Skid Plate

NOTE: The skid plate forward two holes are slotted, it is not necessary to fully remove the forward bolts. Only the rearward bolts must be fully removed.

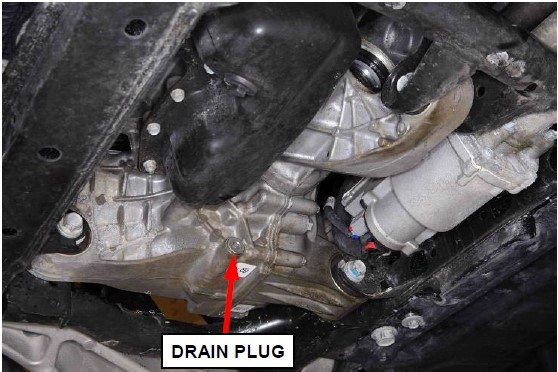

- Drain and properly dispose of the front axle differential lubricant (Figure 12).

Figure 12 – Drain Lubricant

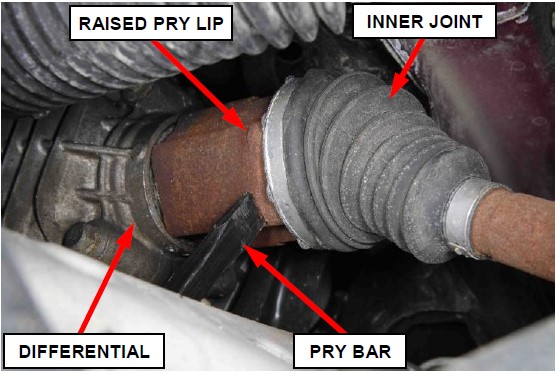

- Using a pry bar, separate the inner half shaft joints from the front differential (Figure 13).

Figure 13 – Inner Half Shaft Joint

NOTE: It is not necessary to completely remove the half shafts from the vehicle, as long as they are fully disengaged from the front differential.

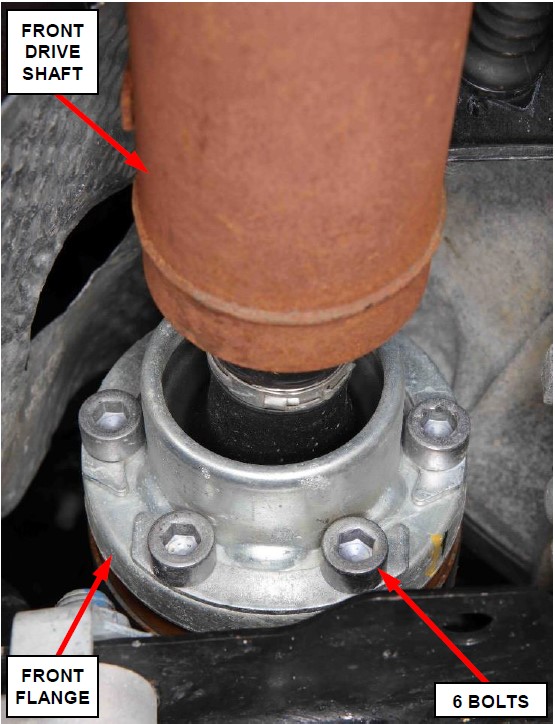

- Remove and DISCARD the six bolts securing the front drive shaft joint flange to the front differential pinion flange (Figure 14).

- Separate the front drive shaft joint flange from the front differential pinion flange (Figure 14).

Figure 14 – Front Drive Shaft Joint

- Support and secure the front differential on a suitable transmission jack.

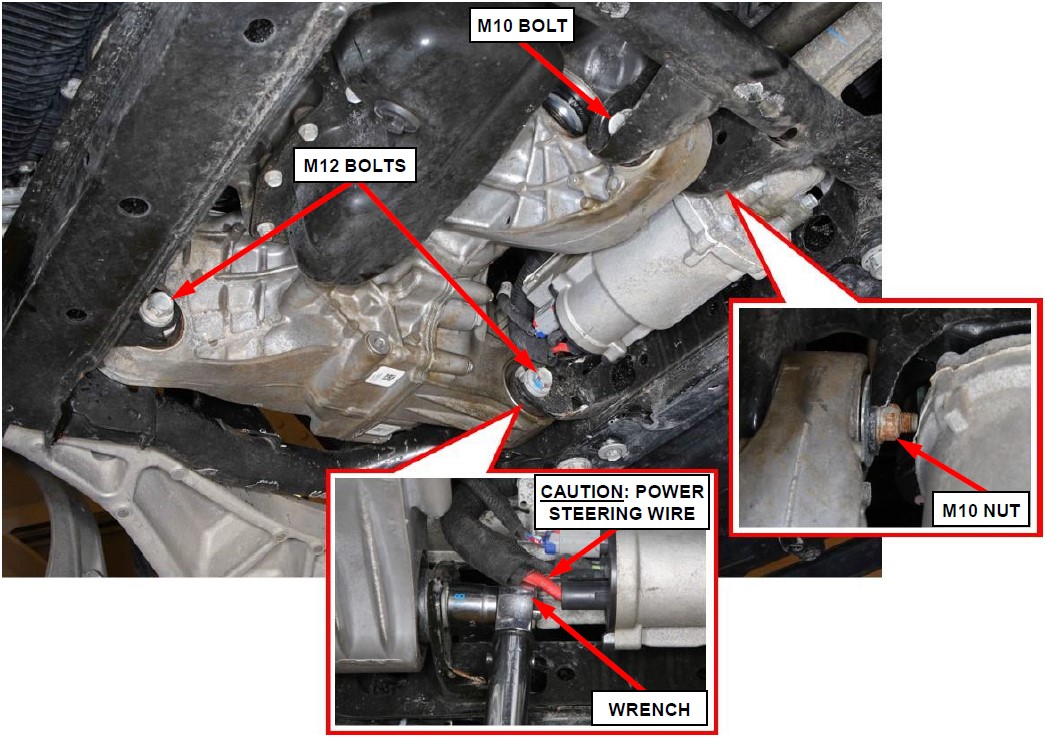

- Remove and DISCARD the nut and three bolts securing the front differential to the suspension cradle (Figure 15).

Figure 15 – Differential Fasteners

CAUTION: Take care to not damage the power steering gear electrical wire insulation during front differential bushing bolt removal.

- Lower the transmission jack while removing the front differential from the vehicle.

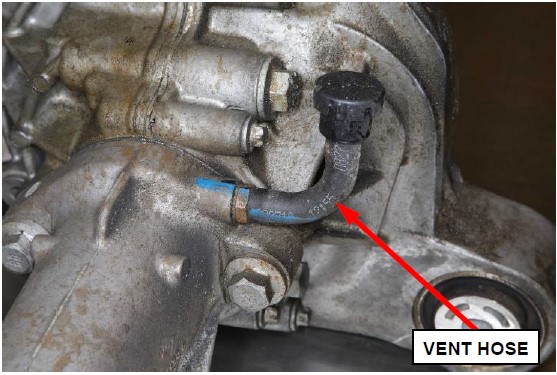

CAUTION: During front differential removal, do not tilt the front differential too much toward the vent hose or the vent internal filter may saturate with differential lubricant rendering it inoperable. If that happens, the vent will require replacement (Figure 16).

- Remove and SAVE the vent hose from the OLD front differential (Figure 16).

- Remove the OLD front differential from the transmission jack and secure the NEW front differential on the transmission jack.

Figure 16 – Differential Vent Hose

- Continue with Section B Front Axle Differential Installation.

B. Front Axle Differential Installation

- Install the vent hose to the NEW front differential (Figure 16).

- Using the transmission jack, raise and position the NEW front differential into the vehicle.

CAUTION: During front differential installation, do not tilt the front differential too much toward the vent hose or the vent internal filter may saturate with differential lubricant rendering it inoperable. If that happens, the vent will require replacement (Figure 16).

- Install NEW fasteners that secure the front differential to the suspension cradle.

Tighten the fasteners to:

- Bolts M12: 118 N·m (87 ft. lbs.) (Figure 15).

- Bolt and Nut M10: 61 N·m (45 ft. lbs.) (Figure 15).

- Remove the transmission jack.

- Ensure vent hose orientation is correct, facing upward (Figure 16).

- Install the front drive shaft joint flange to the front differential pinion flange (Figure 14).

- Install NEW fasteners securing the front drive shaft joint to the front differential pinion flange. Tighten the fasteners to 55 N·m (41 ft. lbs.) (Figure 14).

- Remove the shipping plugs from the NEW front differential (Figure 17).

Figure 17 – Shipping Plugs

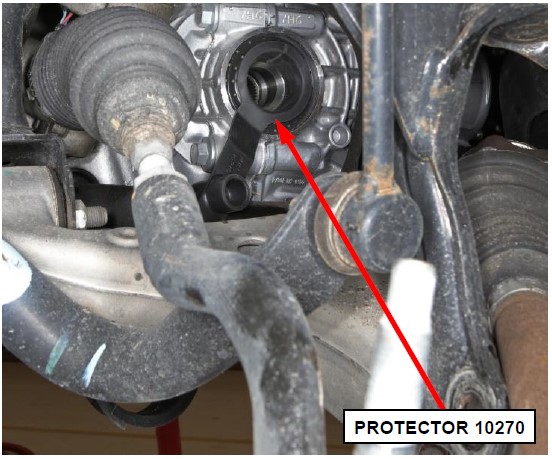

- Using Half Shaft Protector 10270, protect the front differential seals while inserting the inner half shaft joints into the front differential. Ensure the joint is fully inserted and retaining clip is engaged (Figure 18).

Figure 18 – Half Shaft Seal Protector

NOTE: The NEW front differential comes filled with lubricant. It is NOT necessary to check the lubricant level unless lubricant was spilled during shipping or during the installation process. If lubricant loss occurred, Refer to the detailed service procedures available in DealerCONNECT / Service Library under: Service Info > 03 – Differential and Driveline > Front Axle – 195FIA > Standard Procedure – Fluid Drain and Fill.

- If equipped: Install the skid plate to the front suspension cradle. Tighten the fasteners to 28 N·m (21 ft. lbs.) (Figure 11).

- Lower the vehicle slightly to an appropriate working height.

- Install NEW washers between the outer half shaft joint and hub (Figure 10).

- While positioning the steering knuckle down and away, insert the outer half shaft joint into the hub (Figure 10).

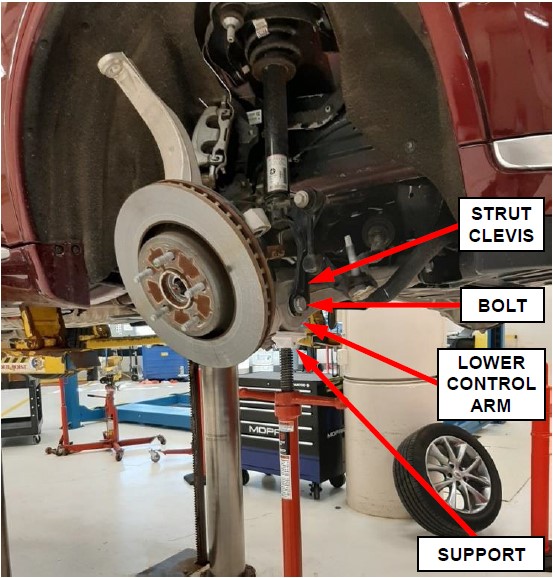

- Raise and support the lower control arm in order to insert the NEW bolt through the front strut clevis bracket and the lower control arm (Figure 19).

- Install the NEW nut to the strut clevis bracket bolt, then raise the lower control arm to vehicle ride height before tightening the strut clevis bracket nut to 255 N·m (188 ft. lbs.) (Figure 9).

- Position the upper control arm ball joint into the steering knuckle then install the NEW nut securing the ball joint. Tighten the nut to 165 N·m (122 ft. lbs.) (Figure 7).

Figure 19 – Support Lower Control Arm

- Remove the support from under the lower control arm.

- Position the tie rod ends into the steering knuckle then install the NEW nut securing the tie rod end. Tighten the nut to 95 N·m (70 ft. lbs.) (Figure 5).

- Install the brake caliper and adaptor bracket assembly into position on the brake rotor and steering knuckle. Ensure the brake hose is properly routed and not twisted (Figure 3).

- Install the bolts securing the brake caliper adaptor bracket to the steering knuckle. Tighten the bolts to 170 N·m (125 ft. lbs.) (Figure 3).

- Install the wheel speed sensor wire harness to the retainers along the brake hose (Figure 2).

NOTE: If the cable tie fastener securing the wheel speed sensor wire to the steering knuckle breaks, use part number 68303208AA as a replacement.

- Install the NEW hub nut to the halfshaft. Tighten the nut to 310 N·m (229 ft. lbs.) (Figure 1).

NOTE: Always install a new hub nut. The original hub nut is one-time use only and should be discarded when removed.

- Install the front tire and wheel assemblies. Tighten the lug nuts in a star pattern to 176 N·m (130 ft. lbs.).

- Pump the brake pedal to ensure the front brakes pads come in contact with the front rotors.

- Connect the battery negative cables.

- Render the old recalled front differential unusable and discard.

- Return the vehicle to inventory or the customer.

Completion Reporting and Reimbursement

Claims for vehicles that have been serviced must be submitted on the DealerCONNECT Claim Entry Screen located on the Service tab. Claims paid will be used by FCA to record recall service completions and provide dealer payments.

Use the following labor operation numbers and time allowances:

| Labor Operation Number | Time Allowance | |

| Replace Front Axle Differential | 02-W2-21-82 | 1.6 hours |

| Floor Plan Reimbursement | 95-95-95-97 | Calculate See Below |

Floor Plan Reimbursement represents the vehicle’s average daily allowance (see table below) multiplied by the number of days the vehicle was in dealer inventory and not available for sale. This reimbursement is limited to the number of days from the date of the stop sale to the date that the remedy was made available. Note: If the vehicle was received by your dealership (KZX date) AFTER the stop sale date, you will use the KZX date instead of the stop sale date. For this Recall, the stop sale was initiated on 04/02/2020 and the remedy was made available on 05/21/2020, therefore, the number of days cannot exceed 49 days.

Add the cost of the recall parts package plus applicable dealer allowance to your claim.

NOTE: See the Warranty Administration Manual, Recall Claim Processing Section, for complete recall claim processing instructions.

Dealer Notification

To view this notification on DealerCONNECT, select “Global Recall System” on the Service tab, then click on the description of this notification.

Owner Notification and Service Scheduling

All involved vehicle owners known to FCA are being notified of the service requirement by first class mail. They are requested to schedule appointments for this service with their dealers. A generic copy of the owner letter is attached.

Vehicle Lists, Global Recall System, VIP and Dealer Follow Up

All involved vehicles have been entered into the DealerCONNECT Global Recall System (GRS) and Vehicle Information Plus (VIP) for dealer inquiry as needed.

GRS provides involved dealers with an updated VIN list of their incomplete vehicles. The owner’s name, address and phone number are listed if known. Completed vehicles are removed from GRS within several days of repair claim submission.

To use this system, click on the “Service” tab and then click on “Global Recall System.” Your dealer’s VIN list for each recall displayed can be sorted by: those vehicles that were unsold at recall launch, those with a phone number, city, zip code, or VIN sequence.

Dealers must perform this repair on all unsold vehicles before retail delivery. Dealers should also use the VIN list to follow up with all owners to schedule appointments for this repair.

Recall VIN lists may contain confidential, restricted owner name and address information that was obtained from the Department of Motor Vehicles of various states. Use of this information is permitted for this recall only and is strictly prohibited from all other use.

Additional Information

If you have any questions or need assistance in completing this action, please contact your Service and Parts District Manager.

Customer Services / Field Operations

FCA US LLC

This notice applies to your vehicle,

[Model Year and Model] VIN XXXXXXXXXXXXXXXXX W22/NHTSA 20V-183

LOGO

VEHICLE PICTURE

YOUR SCHEDULING OPTIONS

- Call the FCA Recall Assistance Center at 1-800-853-1403. An agent can confirm part availability and help schedule an appointment

- Visit recalls.mopar.com, scan the QR code below, or download the Mopar Owner’s Companion App.

QR Code

Get access to recall notifications, locate your nearest dealer, and more through this website or Mopar Owner’s Companion App. You will be asked to provide your Vehicle Identification Number (VIN) to protect and verify your identity. The last eight characters of your VIN are provided above.

DEALERSHIP INSTRUCTIONS

Please reference Safety Recall W22.

IMPORTANT SAFETY RECALL

Front Axle Differential

Dear [Name],

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

FCA US has decided that a defect, which relates to motor vehicle safety, exists in certain [2019 Model Year (WK) Jeep® Grand Cherokee and 2019 Model Year (WD) Dodge Durango] vehicles equipped with a 3.6L engine and four-wheel drive single speed transfer case.

It is extremely important to take steps now to repair your vehicle to ensure the safety of you and your passengers.

WHY DOES MY VEHICLE NEED REPAIRS?

The front axle differential on your vehicle [1] may have been assembled with pinion gears that are not hardened. This may result in the teeth of the gears wearing off, which can cause a loss of engagement between the pinion gears and the side gears. If both pinion gears have their teeth sufficiently worn off, torque cannot be transferred between the front wheels and the driveline. Because the single speed transfer case differential is open, the wheels rotate freely which results in a loss of motive power while the vehicle is in motion and a loss of the PARK function while stationary. In some circumstances, prior to a loss of motive power and/or inadvertent vehicle movement, the operator may notice a gear whine or a grinding noise. A loss of motive power or a loss of PARK function can cause a vehicle crash without prior warning and/or injury to others outside the vehicle.

HOW DO I RESOLVE THIS IMPORTANT SAFETY ISSUE?

FCA US will repair your vehicle [2] free of charge (parts and labor). To do this, your dealer will replace the front axle differential. The estimated repair time is two hours. In addition, your dealer will require your vehicle for proper check-in, preparation, and check-out during your visit, which may require more time. Your time is important to us, so we recommend that you schedule a service appointment to minimize your inconvenience. Please bring this letter with you to your dealership.

TO SCHEDULE YOUR FREE REPAIR,

CALL YOUR CHRYSLER, DODGE, JEEP OR RAM DEALER TODAY

WHAT IF I ALREADY PAID TO HAVE THIS REPAIR COMPLETED?

If you have already experienced this specific condition and have paid to have it repaired, you may visit www.fcarecallreimbursement.com to submit your reimbursement request online. [3] Once we receive and verify the required documents, reimbursement will be sent to you within 60 days. If you have had previous repairs performed and/or already received reimbursement, you may still need to have the recall repair performed.

We apologize for any inconvenience, but are sincerely concerned about your safety. Thank you for your attention to this important matter.

Customer Assistance/Field Operations

FCA US LLC

Mr. Mrs. Customer

1234 Main Street

Hometown, MI 48371

[1] If you no longer own this vehicle, please help us update our records. Call the FCA Recall Assistance Center at 1-800-853-1403 to update your information.

[2] If your dealer fails or is unable to remedy this defect without charge and within a reasonable time, you may submit a written complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Ave., S.E., Washington, DC 20590, or you can call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-4249153), or go to safercar.gov.

[3] You can also mail in your original receipts and proof of payment to the following address for reimbursement consideration: FCA Customer Assistance, P.O. Box 21-8004, Auburn Hills, MI 48321-8007, Attention: Recall Reimbursement.

Note to lessors receiving this recall notice: Federal regulation requires that you forward this recall notice to the lessee within 10 days.

2 Affected Products

Vehicles

11 Associated Documents

ISSUED Owner Notification Letter(Part 577)

RCONL-20V183-8785.pdf 519.174KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577) – Front Axle (Already Remedied)

RCONL-20V183-1035.pdf 519.161KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Dealer Notification re Recall of Jeeps re pinion gears not hardened

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Dealer Notification re New Safety Recall Advanced Communication – W22

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-20V183-1879.PDF 215.797KB

Loading...

Loading...

Recall Acknowledgement

RCAK-20V183-2056.pdf 288.501KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-20V183-3662.pdf 2337.313KB

Loading...

Loading...

Recall Quarterly Report #1, 2020-2

RCLQRT-20V183-8752.PDF 211.141KB

Differential - 2019 Jeep Grand Cherokee & Dodge Durango 21">

Loading...

Differential - 2019 Jeep Grand Cherokee & Dodge Durango 21">

Loading...

Recall Quarterly Report #3, 2020-4

RCLQRT-20V183-9882.PDF 211.326KB

Loading...

Loading...

Recall Quarterly Report #2, 2020-3

RCLQRT-20V183-8649.PDF 211.239KB

Loading...

Loading...

Renotification Notice

RCRN-20V183-9962.pdf 137.437KB

Loading...

Loading...

Latest Recalls Documents

- The only full synthetic premium gear oil in a flexible pouch, making it easer to use and work in tight spaces

- Valvoline Extended Protection Flex fill Full Synthetic Gear Oil offers next-level performance with up to 4X better gear wear protection than our conventional formula to maximize gear life

- Meets the demands of conventional and limited slip rear differentials where API GL-5 is specified, as well as non-synchronized manual transmissions that require API GL-4 or MT-1 fluid

- Outstanding thermal stability and high and low temperature protection

- Mobil 1 Synthetic Gear Lube LS is a supreme performance, synthetic, multipurpose, automotive gear lubricant

- Meet or exceed the highest level of performance requirements of many modern passenger vehicles – including limited slip applications

- Helps protect against thermal and oxidative degradation, wear and corrosion, and viscosity loss associated with premature shearing

- Promotes outstanding power transfer performance - even in some of the most severe driving conditions

- Sold as 6 pack

- Extreme pressure additives deliver outstanding high pressure performance, load carrying capacity and durability for towing and hauling

- Contains a limited slip additive for optimal clutch pack performance

- Daily Protection gear lubricant helps prevent noise and chattering, while protecting gear teeth from wearing out prematurely

- Outstanding high and low temperature protection ranges from -30F to 350F for dependable year-round coverage

- Fights rust and corrosion with corrosion inhibitors and safeguards against impurities, oxidation and thermal breakdown

- Viscosity Rating: Offers a viscosity of 75W-90, ensuring optimal performance in a wide temperature range.

- Full Synthetic Composition: Made from synthetic base oils, providing superior lubrication and thermal stability.

- Improved Wear Protection: Reduces wear on gears and bearings, extending the life of drivetrain components.

- Temperature Stability: Maintains performance in extreme temperatures, preventing breakdown and maintaining viscosity.

- High Load Carrying Capacity: Designed to handle heavy loads, making it ideal for demanding applications.

- Contains extraordinary anti-wear and lubricity agents, ensuring exceptional protection against wear and reducing drag

- Helps to control heat

- Incorporates Lucas cutting-edge additive technology derived from top-rated Lucas Heavy Duty Oil Stabilizer, the number one supplemental oil in the heavy-duty industry

- Available in 1 quart and 1 gallon bottle sizes

- Fit type: Vehicle Specific

- Affordable solutions

- Replaces OEM number: Lucas Oil: 10047

- Excellent for use in limited-slip differentials

- Packaging May Vary

- Mobil 1 Synthetic Gear Lube Ls 75W-90 Mobil 1 Synthetic Gear Lube Ls 75W-90 Is A Supreme Performance, Synthetic, Multi-Purpose, Sae 75W-90 Automotive Gear Lubricant Designed To Meet The Highest Level Of Performance Requirements Of Modern Passenger Vehicles In All Types Of Operating Conditions, Including Limited Slip Applications, As Well As Delivering Outstanding Power Transfer Performance

- Compared To Conventional Hypoid Gear Lubricants, Mobil 1 Synthetic Gear Lube Ls 75W-90 Performs Exceptionally Well Over A Wide Range Of Temperatures

- Through Creativity, Productivity And Innovation - This Brand Continues To Develop The Finest Automotive Accessories

- Model Number : 104361-UNIT

- Heavy duty

- High performance

- Stands up to high temperatures

- Package Dimensions: 30.48 H x 37.465 L x 30.48 W (centimetres)

- Package Weight: 37.3 pounds

- Country of Origin : China

- Fit type: Vehicle Specific

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.