| “This site contains affiliate links for which OEMDTC may be compensated” |

NUMBER: 08-016-08

GROUP: Electrical

DATE: April 22, 2008

SUBJECT:

Rough Idle and/or MIL Illumination For Any Of The Following DTC’s: P0300 / P0301 / P0302 / P0303 / P0304 / P0315 / P0335 and/or P0606.

OVERVIEW:

This bulletin involves replacing the terminals in the Crankshaft Sensor (CKP) connector. Some vehicles were built with incorrect (oversize) terminals that may cause an intermittent connection at the (CKP) sensor. Vehicles that exhibit a rough idle and/or any of the above listed DTC’s and are built in the suspect build range will require that all (CKP) connector terminals be replaced.

MODELS:

| 2008 | (JS41) | Sebring/Avenger |

| 2008 | (JS27) | Sebring Convertible |

NOTE: This bulletin applies to models equipped with a 2.0L or 2.4L engine (sales codes ECN, ED3 or EDG) built from November 12, 2007 through December 8, 2007 (MDH 1112XX through 1208XX).

SYMPTOM/CONDITION:

Some customers may experience a rough idle and MIL illumination. Further investigation by the technician may find any of the following DTC’s:

- P0300 – Multiple Cylinder Misfire

- P0301 – Cylinder 1 Misfire

- P0302 – Cylinder 2 Misfire

- P0303 – Cylinder 3 Misfire

- P0304 – Cylinder 4 Misfire

- P0315 – No Crank Sensor Learned

- P0335 – Crankshaft Position Sensor Circuit

- P0606 – Internal ECM Processor

DIAGNOSIS:

Using a Scan Tool (StarSCAN) with the appropriate Diagnostic Procedures available in TechCONNECT, verify all engine systems are functioning as designed. If DTC’s are present other then the ones listed in the Symptom/Condition, record them on the repair order, clear DTC’s and wiggle test wires at crankshaft sensor or test drive vehicle as necessary. If DTC’s return other then the ones listed in the Symptom/Condition, repair as necessary before proceeding further with this bulletin.

If the vehicle operator describes or experiences the Symptom/Condition and any of the DTC’s listed are causing a MIL illumination, perform the Repair Procedure.

PARTS REQUIRED:

| Qty. | Part No. | Description |

|---|---|---|

| 1 | 05183453AB | *Wiring Repair Kit (Use Gold Terminals) |

| 1 | NPN | Rosin Core Solder |

| 1 | NPN | Electrical Tape |

NOTE: *Wiring Repair Kit p/n 05183453AB contains both tin plated and gold plated terminals. The gold plated terminals are in a separate bag marked “GOLD” within the kit. Use the gold plated terminals for the purpose of this repair.

SPECIAL TOOLS/EQUIPMENT REQUIRED:

| 10042 | Miller Crimping Tool (or equivalent) |

| NPN | Soldering Iron |

| NPN | Heat Gun |

| CH9401 | StarSCAN Tool |

| CH9404D | StarSCAN Vehicle Cable |

REPAIR PROCEDURE:

NOTE: The Crankshaft Position Sensor is in the rear of the engine block near the transmission

- Disconnect and isolate the negative battery cable.

- Raise vehicle on a suitable hoist.

- Remove heat shield retaining bolts and move heat shield aside.

- Unlock and disconnect the electrical connector to the crankshaft position (CKP) sensor.

- Lower the vehicle.

- Unlock and disconnect the electrical connector to the downstream Oxygen (O2) sensor (1/2).

- Remove downstream O2 sensor (1/2) wire takeout from retainer clip on transmission mount bracket.

- Remove CKP wire retainer metal clip from crankshaft sensor heat shield.

- Pull wire harness up for easy access during wire repairs.

- Carefully cut the tape from protective wrapping near CKP connector and fold wrapping back.

NOTE: If necessary, refer to the detailed wire splice information available in DealerCONNECT > TechCONNECT under: Wiring Tab > Wiring Diagram Information > Wire > Standard Procedure > Wire Splicing for detailed instructions.

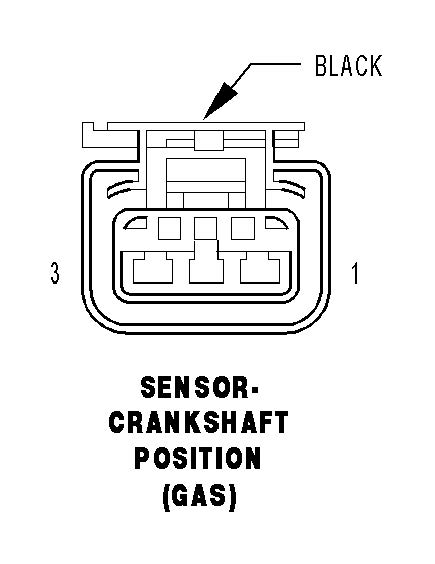

Fig. 1 TERMINAL END VIEW OF CONNECTOR

1 – TERMINAL #1 – PK/YL

2 – TERMINAL #2 – DB/LB

3 – TERMINAL #3 – BR/LB

NOTE: The repair kit contains 3 terminal ends made with standard tin plated ends and 3 terminals (in a separate bag) made with gold plated ends. Use the gold plated ends for this repair.

- Cut the PK/YL wire close to the connector (terminal #1).

- a. Cut one of the new GOLD terminal wires (supplied in kit p/n 05183453AB) to an appropriate length.

- b. Remove 0.5 in (13mm) of insulation from each of the wires.

- c. Place a piece of sealant lined heat shrink tubing, (supplied in kit p/n 05183453AB),on one side of the wire.

- d. Place the strands of wire overlapping each other inside of the splice band.

- e. Using crimping tool, p/n 10042 (or equivalent) crimp the splice band and wirestogether.

- f. Solder the connection together using rosin core type solder only.

- g. Center the heat shrink tubing over the joint and heat using a heat gun, heat the jointuntil the tubing is tightly sealed and sealant comes out of both ends of the tubing.

- Install the new GOLD terminal end into the new CKP connector in cavity #1 ( 1).

- Repeat the above procedure for the DB/LB and install in connector in cavity #2.

- Repeat the above procedure for the BR/LB and install in connector in cavity #3.

- Ensure all terminals are locked into connector by pulling wires gently.

- Pull protective wrap back over CKP wires and tape in place.

- Connect the downstream O2 sensor (1/2) connector until it clicks.

- Connect the downstream O2 sensor (1/2) wire takeout from retainer clip on transmission mount bracket.

- Raise the vehicle.

- Connect the CKP connector to the CKP sensor until it clicks.

- Install the CKP wire retainer metal clip on the heat shield in its original position.

- Install the heat shield and retaining bolts.

- Lower vehicle.

- Connect the negative battery cable.

POLICY:

Reimbursable within the provisions of the warranty.

TIME ALLOWANCE:

| Labor Operation No: | Description | Amount |

|---|---|---|

| 08-94-G3-90 | Crankshaft Sensor – Wire Harness Terminal Replacement – (All 3) (B) | 0.8 Hrs. |

FAILURE CODE:

| ZZ | Service Action |

StarMOBILE DESKTOP CLIENT MAY ALSO BE USED DURING THIS PROCEDURE. StarMOBILE STANDALONE MODE MAY ALSO BE USED DURING THIS PROCEDURE.

Loading...

Loading...